A reversing valve and reversing method for controlling on-off of microfluidic pipeline

A technology of microfluidic control and reversing valve, which is applied in the direction of valve details, valve device, valve operation/release device, etc. It can solve the problems of limited size, large volume, high cost of electromagnetic reversing valve, etc., and achieve manufacturing cost Reduce, reduce the effect of limit size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

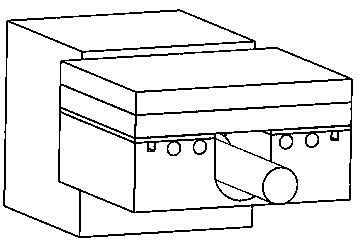

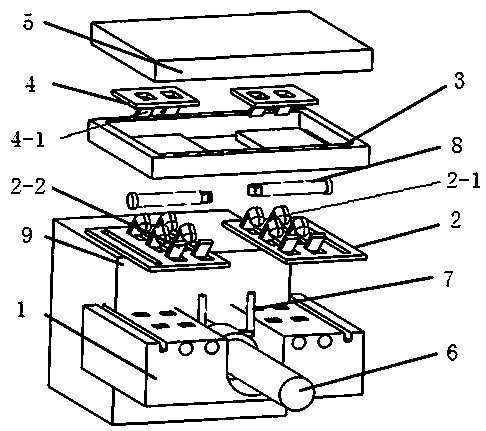

[0029] figure 1 As shown, a push type reversing valve for controlling multi-pipe reversing of the present invention consists of a reversing valve housing part, a cover part, a push rod, an internal splint, a shrapnel plate, a ramp plate, a motor box and a screw rod Stepper motor composition:

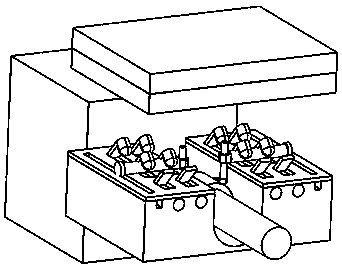

[0030] figure 2 As shown, the horizontal push rod is assembled with the vertical push rod. The horizontal push rod moves inward and outward along the rails on both sides of the shrapnel plate by means of the screw screw. After passing through the shrapnel in the shrapnel state on the shrapnel board, the horizontal push rod presses down the shrapnel. , so the shrapnel enters the hole located on the top of the shell below. The position of the hole is the channel through which the pipeline in the shell passes. The downward pressure of the shrapnel makes the pipeline blocked, and the pipeline is unblocked at the position without the shrapnel, forming a combination of pipeline on-off. , Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com