Cleaning system for digital printing machine conveying mechanism

A technology of digital printing machine and conveying mechanism, applied in the field of cleaning system, which can solve the problems of unsatisfactory cloth lint cleaning effect, reduced service life of conveying belt, no waste water recycling system, etc., so as to avoid work with water and long service life , The effect of less waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

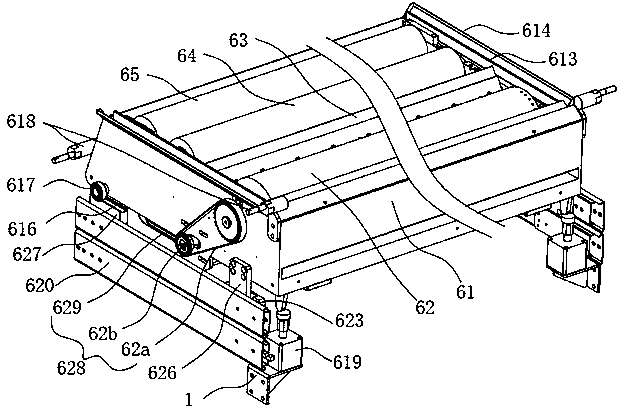

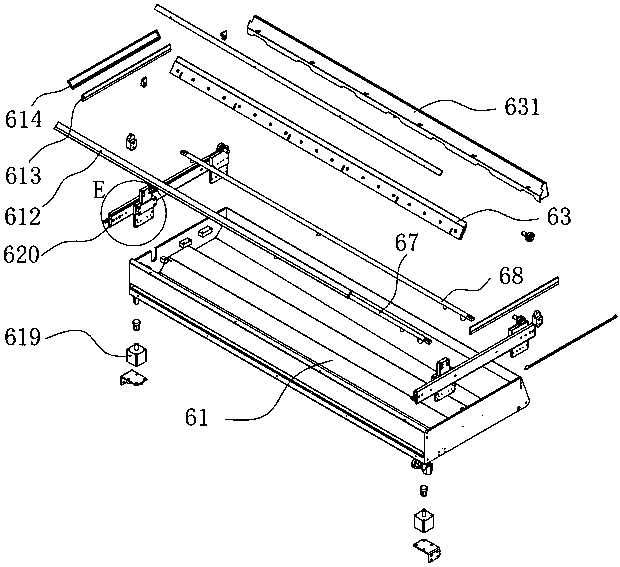

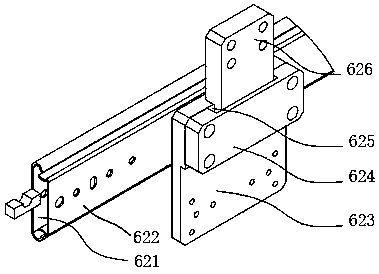

[0037] see Figure 1~Figure 7 , a cleaning system for a conveying mechanism of a digital printing machine preferably implemented in the present invention, including a frame 1, a cleaning mechanism for cleaning the conveying belt 31 of a scanning digital printing machine, and a cleaning water supply system 60 for supplying water to the cleaning mechanism; wherein , the cleaning mechanism can be set up and down on the frame 1, and the cleaning mechanism is located under the conveying belt 31; it is characterized in that the cleaning mechanism includes a cleaning plate 61, a primary brush roller 62, a front sponge roller 64, and a rear sponge roller 65, scraper plate 63, front water spray pipe 67, rear water spray pipe 68, hairbrush driving mechanism 628, air knife 69 for air-drying of conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com