Nickel-cobalt-manganese ternary precursor material and synthetic method thereof

A synthesis method and precursor technology, applied in the field of nickel-cobalt-manganese ternary precursor material and its synthesis, can solve the problem of no synthesis method of precursor material with smaller average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

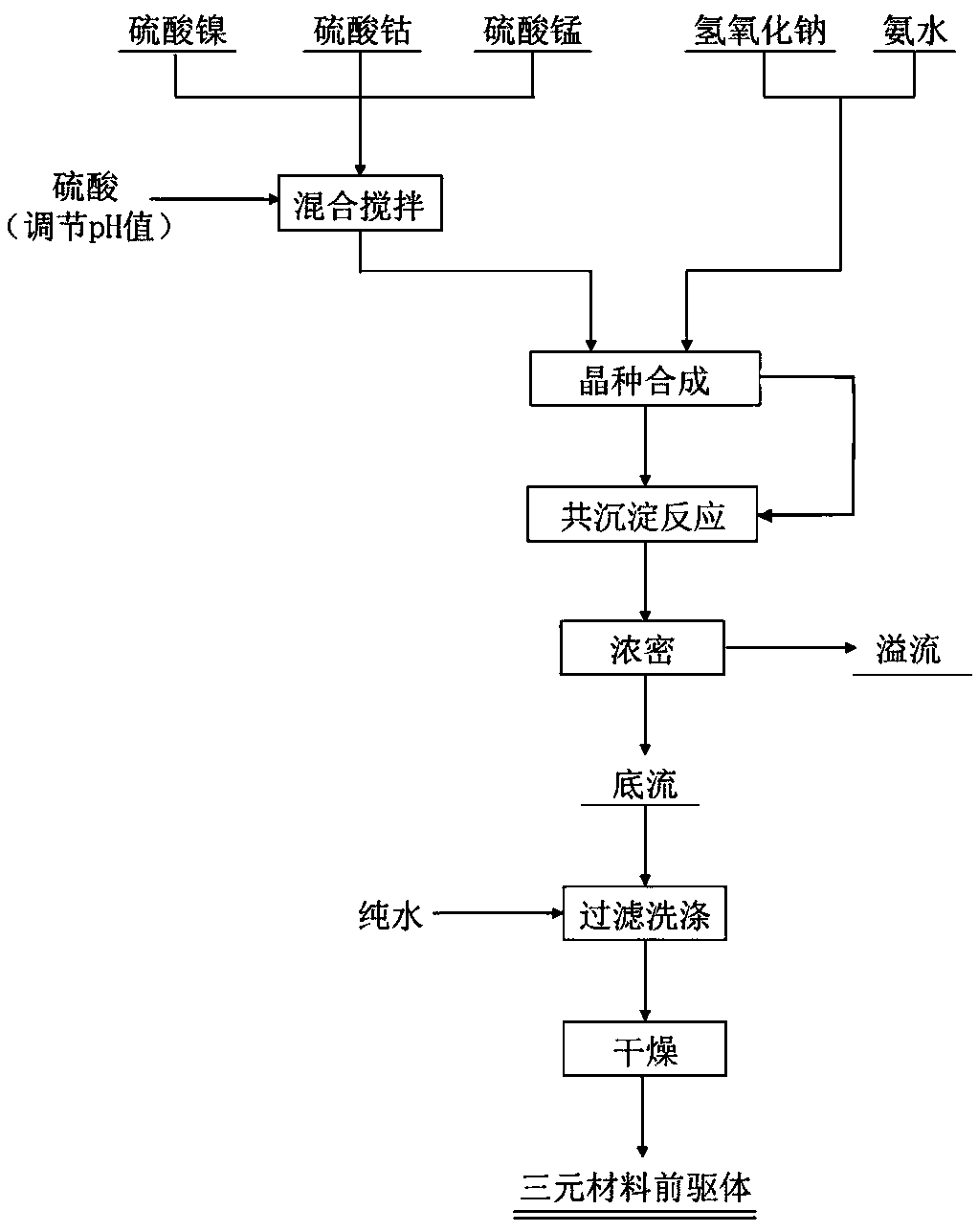

[0031] According to a typical embodiment of the present invention, a method for synthesizing a nickel-cobalt-manganese ternary precursor material is provided. The synthesis method comprises the following steps: preparing a metal salt solution containing nickel sulfate, cobalt sulfate and manganese sulfate, adding the metal salt solution, sodium hydroxide solution and ammonia water into a reactor to synthesize a crystal seed; putting the crystal seed into a co-precipitation reactor The co-precipitation reaction is carried out in the co-precipitation reactor, which contains metal salt solution, sodium hydroxide solution and ammonia water, and the nickel-cobalt-manganese ternary precursor is obtained by controlling the number of seed crystal returns and the reaction time until the particle size reaches a predetermined value. Material.

[0032] Applying the technical solution of the present invention, the synthesized primary particles are used as crystal seeds and added to the pre...

Embodiment 1

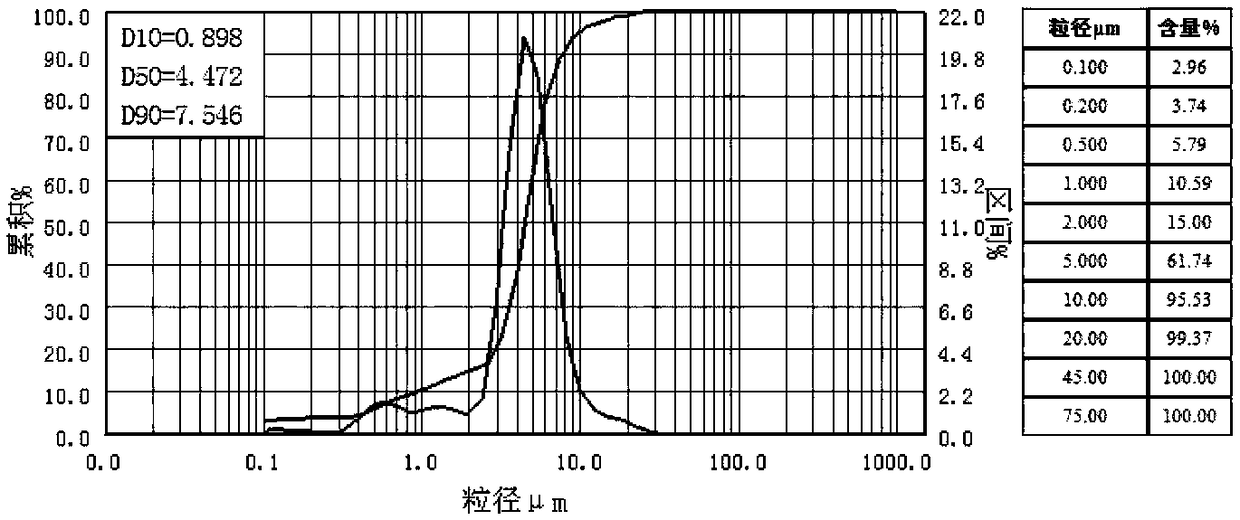

[0045] Prepare nickel sulfate, cobalt sulfate, and manganese sulfate solutions with a concentration of 1.5mol / L according to the prescribed ratio (5:2:3) and mix them uniformly. The concentration of the sodium hydroxide solution is 4mol / L. Mix the metal salt solution, Sodium hydroxide solution and ammonia water (0.5mol / L) are added in the seed crystal synthesis kettle with a certain flow rate. The parameters that need to be controlled during the reaction process are stirring speed (1000r / min), slurry temperature (55°C) and pH value (10.5), etc., and the seed crystal preparation time is 4h. Then add the crystal seeds into the co-precipitation reactor, and return the co-precipitation reaction several times (5 times) in the manner of full seed crystal return. The parameters that need to be controlled in this process include stirring speed (700r / min), reaction temperature (60°C ), pH value (12.0), densely filtered, washed and dried to become a ternary material precursor. The part...

Embodiment 2

[0047] Prepare nickel sulfate, cobalt sulfate, and manganese sulfate solutions with a concentration of 2.5mol / L according to the prescribed ratio (5:2:3) and mix them uniformly. The concentration of the sodium hydroxide solution is 3mol / L. Mix the metal salt solution, Sodium hydroxide solution and ammonia water (1.0mol / L) were added into the seed crystal synthesis kettle at a certain flow rate. The parameters that need to be controlled during the reaction process are stirring speed (800r / min), slurry temperature (60°C) and pH value (11.0), etc., and the seed crystal preparation time is 4h. Then add the crystal seeds into the co-precipitation reactor, and return the co-precipitation reaction several times (4 times) in the way of full seed crystal return. The parameters that need to be controlled in this process are stirring speed (600r / min), reaction temperature (58 ℃ ), pH value (11.5), densely filtered, washed and dried to become a ternary material precursor. The particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com