Method for extracting cobalt and nickel from manganese, cobalt and nickel waste residue

A manganese-cobalt-nickel, cobalt-nickel technology, applied in the field of heavy metal extraction, can solve the problems of high recovery rate of cobalt and nickel, unutilized nickel and cobalt, environmental pollution, etc., and achieves high recovery rate, simple production conditions, and low consumption. Effect

Active Publication Date: 2014-05-07

GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

View PDF2 Cites 35 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is to provide a method for extracting cobalt and nickel from waste slag of manganese, cobalt and nickel. The production conditions are relatively simple, efficient grouping is possible, and the recovery rate of cobalt and nickel is high, which can solve the problem of electrolytic manganese production. The problem of waste of resources and environmental pollution caused by the failure to utilize the valuable elements nickel and cobalt in the waste residue

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

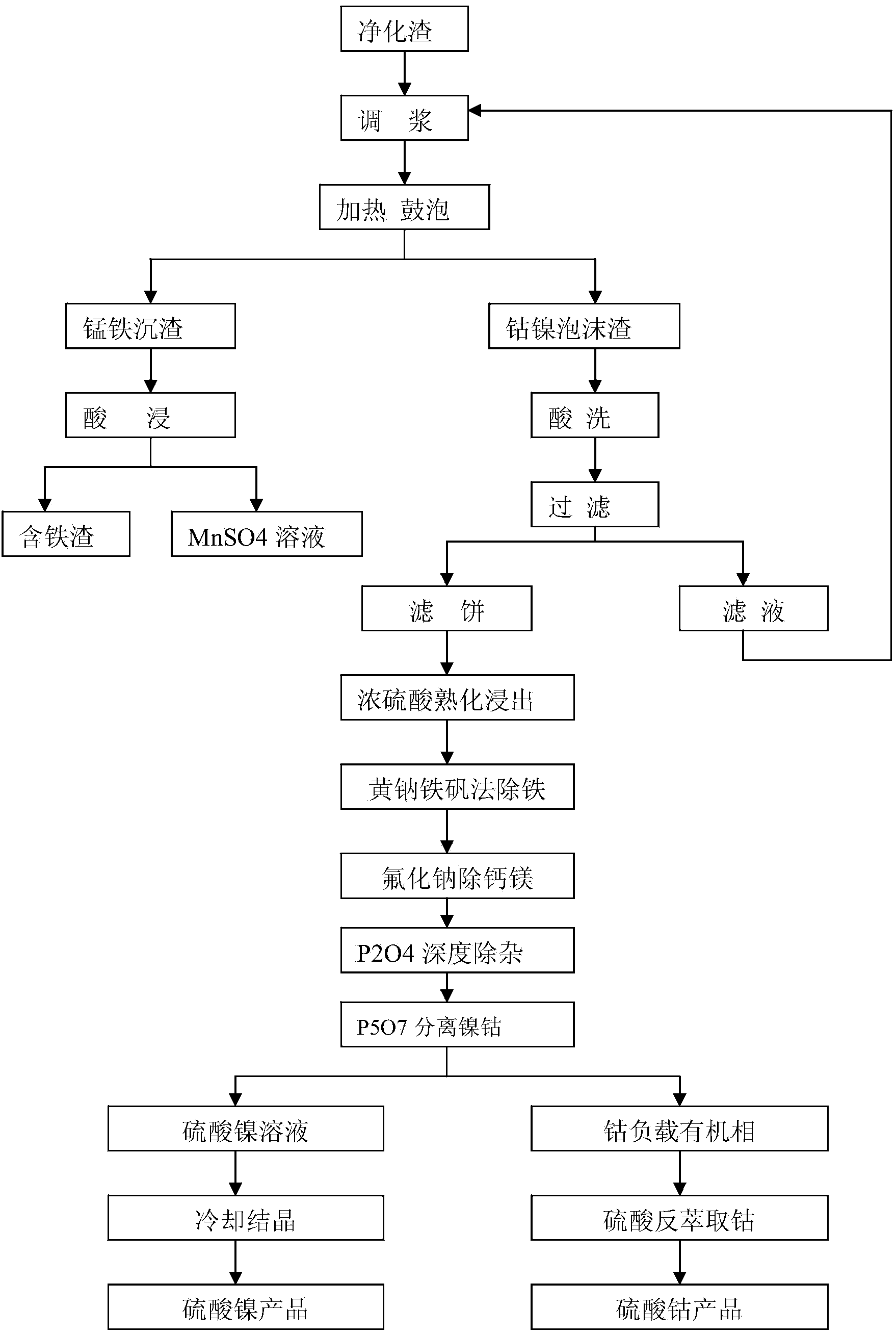

[0023] figure 1 It is a process flow chart of extracting nickel from manganese, cobalt and nickel waste slag in the embodiment of the present invention.

[0024] See figure 1 The method for extracting cobalt and nickel in the manganese-cobalt-nickel waste slag provided by the invention comprises the following steps:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

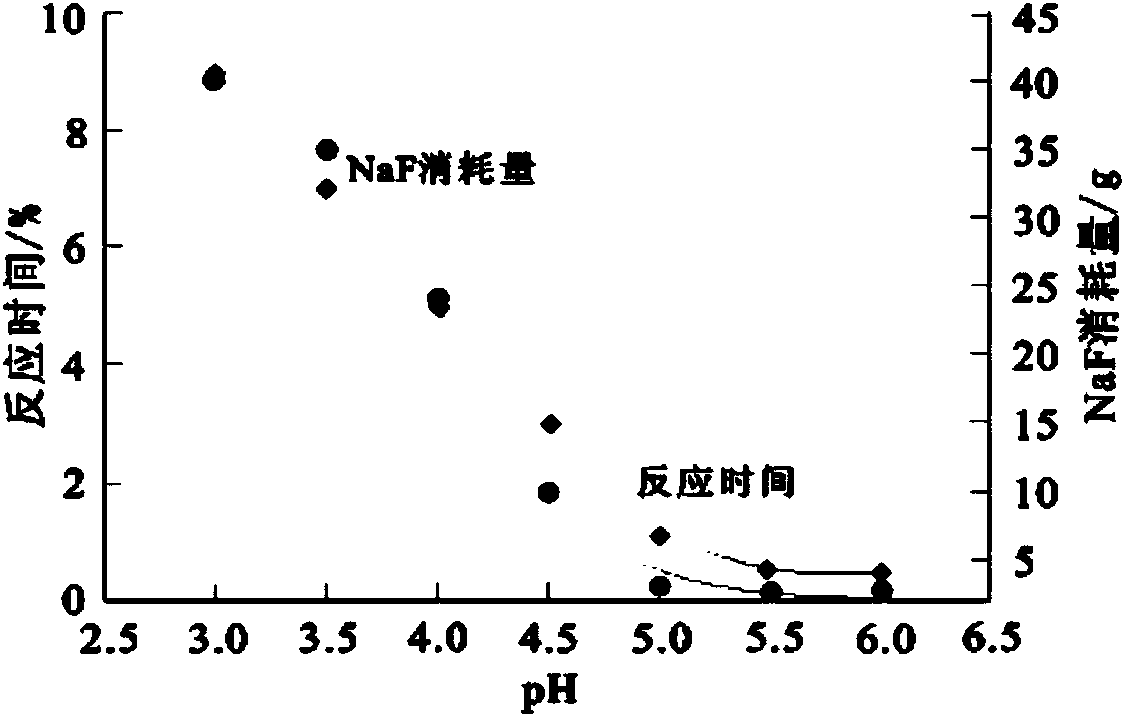

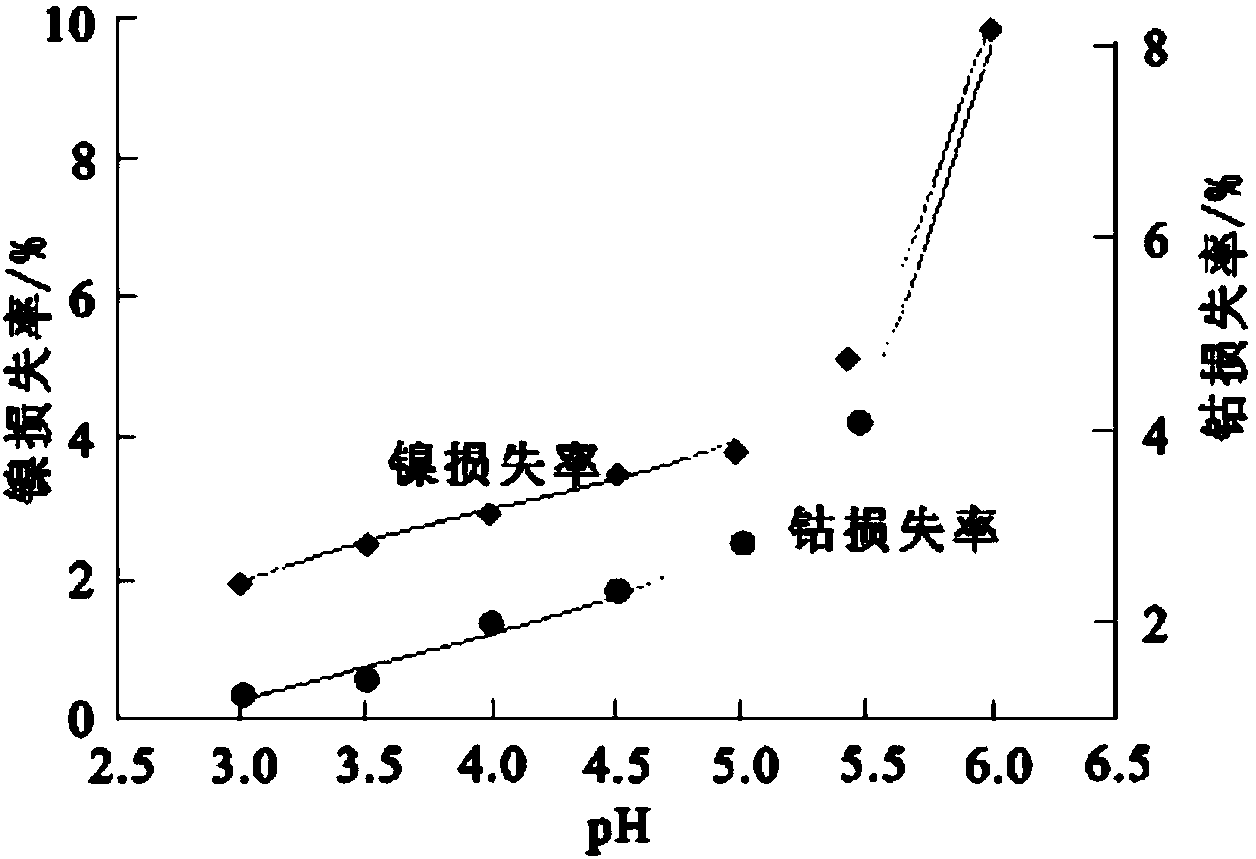

The invention discloses a method for extracting cobalt and nickel from a manganese, cobalt and nickel waste residue. The method sequentially comprises the following steps: a) adding water into the manganese, cobalt and nickel waste residue in a solid-to-liquid ratio of 1:(2-5) to size, and heating and bubbling under stirring to obtain cobalt and nickel foaming slags and ferromanganese sediments; b) heating, pickling and filtering the cobalt and nickel foaming slags to obtain a cobalt and nickel filter cake; c) curing and leaching the cobalt and nickel filter cake by concentrated sulfuric acid to obtain cobalt and nickel liquor; d) removing impurities in the cobalt and nickel liquor to remove impurities such as copper, iron, calcium, magnesium, manganese and zinc, wherein the mass concentration of impurities in the liquor is reduced to below 0.01g / L; e) extracting and separating the cobalt and nickel liquor without impurities by a P507 extractant to obtain nickel sulfate liquor and a cobalt-loaded organic phase; and f) cooling and crystallizing the nickel liquor, and recovering a nickel sulfate product, and carrying out reverse extraction on the cobalt-loaded organic phase by sulfuric acid to obtain cobaltous sulfate liquor. According to the invention, the production condition is relatively simple, efficient grouping is realized, and the recovery rate of cobalt and nickel is high.

Description

technical field [0001] The invention relates to a method for extracting heavy metals, in particular to a method for extracting cobalt and nickel from waste slag of manganese, cobalt and nickel. Background technique [0002] Cobalt and nickel are important non-ferrous metal resources that are in short supply in my country. Most of the manganese ores in southern China, especially in Guangxi, contain cobalt and nickel. [0003] When hydrometallurgy is used to produce electrolytic metal manganese, electrolytic manganese dioxide, manganese sulfate and other products, cobalt and nickel in manganese ore will enter the leaching solution in the first step together with manganese. During the leaching process of manganese ore, when the pH of the leaching end point is controlled to be 5 to 5.4, most of the impurity elements such as Fe can be removed, but Co and Ni still remain in the solution and must be recovered. At present, the method of deeply purifying impurity elements such as Co...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B7/00C22B23/00

CPCY02P10/20

Inventor 陈奇志万维华李学锋高峰周克盛陆超

Owner GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com