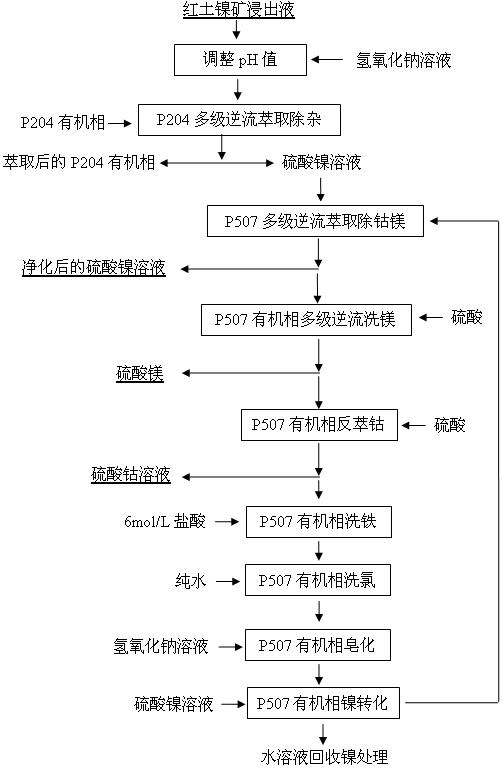

Method for treating red soil nickel ore leaching liquid

A technology of laterite nickel ore and treatment method, which is applied in the field of extraction and separation of nickel, cobalt and magnesium, which can solve the problems of large consumption, high operating cost and inability to separate nickel and cobalt, and achieve the effects of low cost, simple process and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] After the laterite nickel ore is leached with sulfuric acid at atmospheric pressure, impurity removal of yellow sodium iron vanadium, solid-liquid separation, concentration and acid dissolution, the pH value of the solution is adjusted to 3.5, and the organic extractant containing 10% P204 and 90% sulfonated kerosene, Under the condition that the volume ratio of the organic phase to the aqueous phase is O / A=1:5, iron, manganese, copper, zinc and other impurities are removed by 12-stage countercurrent solvent extraction, and the obtained raffinate components are: Fe, Mn, Cu, Zn is less than 0.001g / L; cobalt 0.48g / l, magnesium 6.62g / l, nickel 70.36g / l. The raffinate is extracted with an organic extractant containing 10% P507 and 90% sulfonated kerosene under the condition that the volume ratio of the organic phase to the aqueous phase is O / A=1:5, and the cobalt Magnesium is extracted into the P507 organic phase and nickel remains in the aqueous phase. The treatment steps...

Embodiment 2

[0034] After the laterite nickel ore is leached with sulfuric acid under atmospheric pressure, impurity removal of yellow sodium iron vanadium, solid-liquid separation, concentration and acid dissolution, the pH value of the solution is adjusted to 5.5, and the organic extractant containing 25% P204 and 75% sulfonated kerosene, Under the condition that the volume ratio of the organic phase to the aqueous phase O / A=1:1, iron, manganese, copper, zinc and other impurities were removed by three-stage countercurrent solvent extraction, and the raffinate components obtained were: Fe, Mn, Cu, Zn is less than 0.001g / L; cobalt 0.55g / l, magnesium 7.5g / l, nickel 68.62g / l. The raffinate is extracted with an organic extractant containing 25% P507 and 75% sulfonated kerosene under the condition that the volume ratio of the organic phase to the aqueous phase is O / A=1:1, and the cobalt Magnesium is extracted into the P507 organic phase and nickel remains in the aqueous phase. The treatment s...

Embodiment 3

[0036] After the laterite nickel ore is leached with sulfuric acid under atmospheric pressure, impurity removal of yellow sodium iron vanadium, solid-liquid separation, concentration and acid dissolution, the pH value of the solution is adjusted to 4.5, and the organic extractant containing 15% P204 and 85% sulfonated kerosene, Under the condition that the volume ratio of the organic phase to the aqueous phase is O / A=1:3, iron, manganese, copper, zinc and other impurities are removed by 10-stage countercurrent solvent extraction, and the raffinate components obtained are: Fe, Mn, Cu, Zn is less than 0.001g / L; cobalt 0.41g / l, magnesium 5.62g / l, nickel 75.31g / l. The raffinate is extracted with an organic extractant containing 15% P507 and 85% sulfonated kerosene under the condition that the volume ratio of the organic phase to the aqueous phase is O / A=1:4, and the cobalt Magnesium is extracted into the P507 organic phase, and nickel remains in the aqueous phase. The treatment s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com