Method for preparing thin-layer lithium metal anode for all-solid-state lithium-ion battery based on PVD

A lithium-ion battery, metal lithium technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of the limit energy density of all-solid-state lithium-ion batteries, limit the industrialization process of all-solid-state lithium-ion batteries, and the thickness of metal lithium foil. Large and other problems, to achieve the effect of strong bonding, safety assurance, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

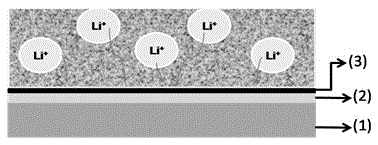

[0023] Such as figure 1 As shown, the thin-layer metal lithium-based negative electrode structure for all-solid-state lithium-ion batteries prepared by PVD method includes a current collector copper foil 1 for commercial lithium-ion battery negative electrodes, a metal lithium-based negative electrode material deposition layer 2, and a protective metal layer 3. In solid-state batteries The protective layer metal is in direct contact with the solid electrolyte in the structure. Concrete preparation steps are as follows:

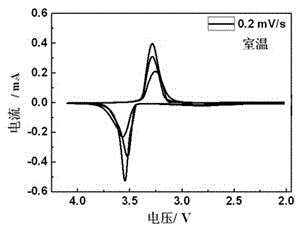

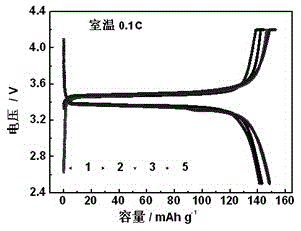

[0024] Using vacuum evaporation technology, a thin layer of lithium metal and a protective layer of metal indium were evaporated successively on the surface of the copper foil of the negative electrode collector of commercial lithium-ion batteries. The thickness of the metal indium protective layer was 20nm, and the thickness of the metal lithium thin layer was 80nm. Solid electrolyte, lithium iron phosphate positive electrode, assembled all-solid-state lithi...

Embodiment 2

[0026] Using magnetron sputtering technology, a thin layer of metal lithium-indium alloy and a protective layer of metallic copper were evaporated successively on the surface of the copper foil of the negative electrode collector of a commercial lithium-ion battery. The thickness of the metallic copper protective layer was 15nm, and the thickness of the metallic lithium-indium alloy thin layer was 65nm, LLZO inorganic solid electrolyte, lithium cobalt oxide positive electrode, assembled all-solid-state lithium-ion battery, the first discharge specific capacity of the battery reaches 135mAhg -1 , Coulombic efficiency reaches 96.4%.

Embodiment 3

[0028] Using ion plating and coating technology, a thin layer of metal lithium-tin alloy and a protective layer of metal indium are evaporated successively on the surface of the copper foil of the negative electrode collector of commercial lithium-ion batteries. The thickness of the metal indium protective layer is 20nm, and the thickness of the metal lithium-tin alloy thin layer is 75nm. , with LAGP inorganic solid-state electrolyte, lithium iron phosphate positive electrode, assemble all-solid-state lithium-ion battery, charge and discharge cycle test at room temperature, the battery's first discharge capacity is 145mAhg -1 , 85% capacity retention after 100 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com