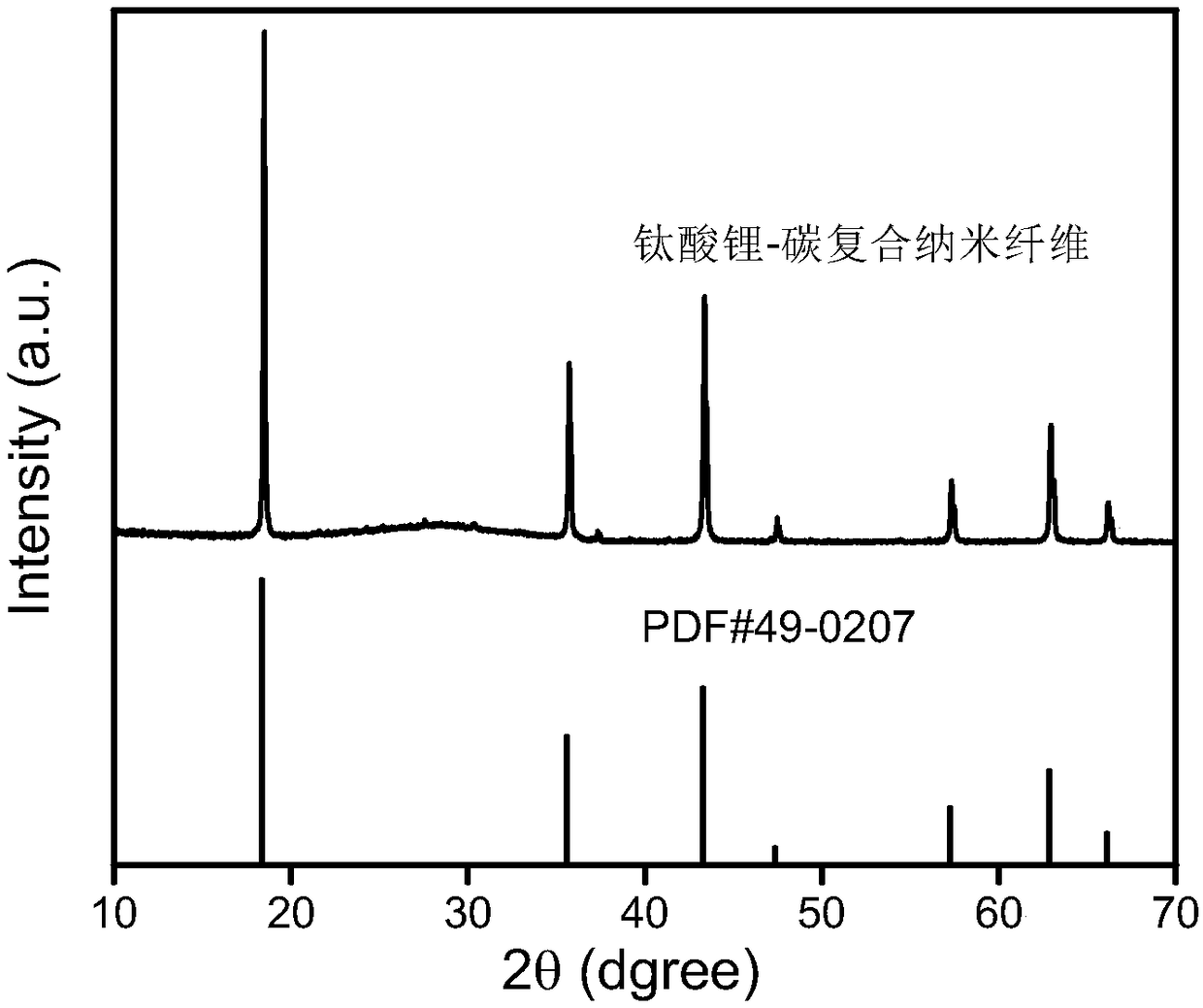

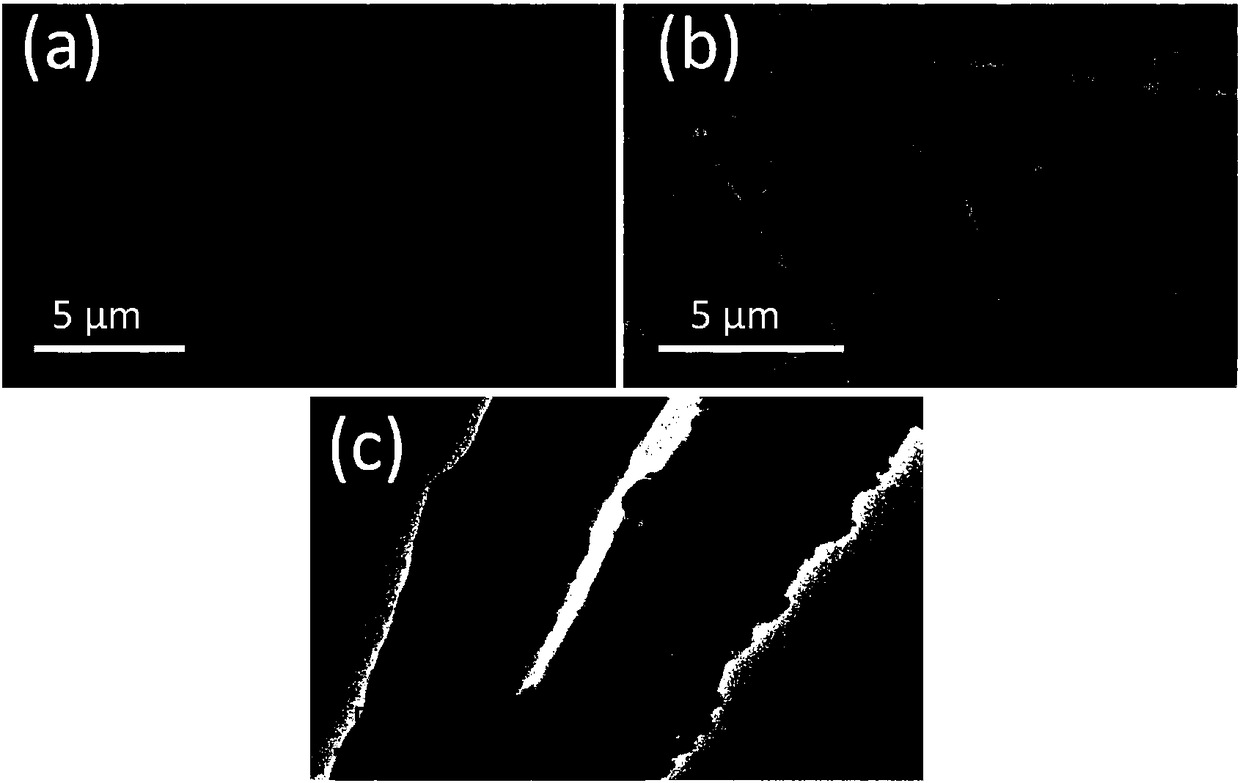

Lithium titanate-carbon nanometer fiber flexible non-woven fabric, preparation method and applications thereof

A carbon nanofiber, lithium titanate technology, applied in microfiber electrodes, active material electrodes, electrical components, etc., can solve the problems of easy aggregation and shedding of lithium titanate particles, lower specific mass capacity, battery capacity attenuation, etc. Ensure cycle stability, improve specific mass capacity, and avoid the effects of agglomeration and shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] In this embodiment, the titanium source compound is metatitanic acid, and the lithium source compound is lithium hydroxide. Include the following steps:

[0040] (1) Accurately measure 40ml of metatitanic acid dispersion liquid with a concentration of 3M in a beaker, add 2.3g of lithium hydroxide, ultrasonicate at a frequency of 60KHz for 1 hour, and then stir at a rotating speed of 600 revs for 6 hours to obtain the first mixed solution ;

[0041] (2) in the step (1), the first mixed solution is transferred to the reactor of 50mL, the hydrothermal reaction is kept at 120 degrees for 8 hours, and cooled to room temperature;

[0042] (3) washing the product obtained by the hydrothermal reaction in step (2) with water 3 times, and placing it in a vacuum oven at 70 degrees to dry for 12 hours to obtain lithium titanate precursor nanoparticles;

[0043] (4) taking 900 mg of the lithium titanate precursor nanoparticles obtained in step (3) and dispersing them in 4 g of dim...

Embodiment 2

[0065] Take the lithium titanate-carbon nanofiber flexible non-woven fabric prepared in Example 1, roll it with a roller press, and directly cut it as a lithium ion battery negative pole piece and a lithium sheet to assemble a lithium ion half battery.

Embodiment 3

[0072] In this embodiment, the titanium source compound is titanium dioxide, and the lithium source compound is lithium carbonate. Include the following steps:

[0073] (1) accurately measure 80ml of titanium dioxide dispersion liquid with a concentration of 0.5M in a beaker, add 1.5g of lithium carbonate, ultrasonicate at a frequency of 30KHz for 2 hours, and then stir at a rotating speed of 800 revs for 2 hours to obtain the first mixed solution;

[0074] (2) in the step (1), the first mixed solution is transferred to the reactor of 100mL, the hydrothermal reaction is kept at 160 degrees for 12 hours, and cooled to room temperature;

[0075] (3) washing the product obtained by the hydrothermal reaction in step (2) with water twice, and placing it in a vacuum oven at 60 degrees for drying for 24 hours to obtain lithium titanate precursor nanoparticles;

[0076] (4) taking 500 mg of the lithium titanate precursor nanoparticles obtained in step (3) and dispersing in 4 g of dim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com