Carbon fiber-zinc oxide nanorod composite material as well as preparation method and application thereof

A technology of zinc oxide nanorods and composite materials, applied in the field of carbon fiber-zinc oxide nanorod composite materials and their preparation, can solve the problems of complicated mixing process and increased battery cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

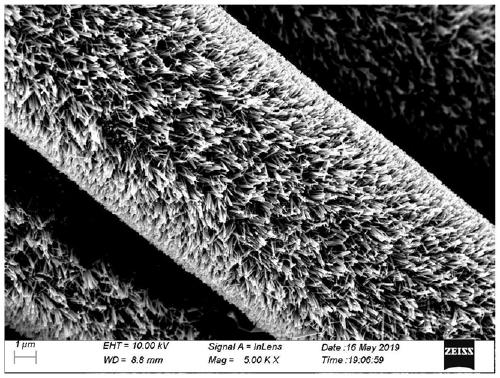

[0035] The invention provides a method for preparing a carbon fiber-zinc oxide nanorod composite material, comprising the following steps:

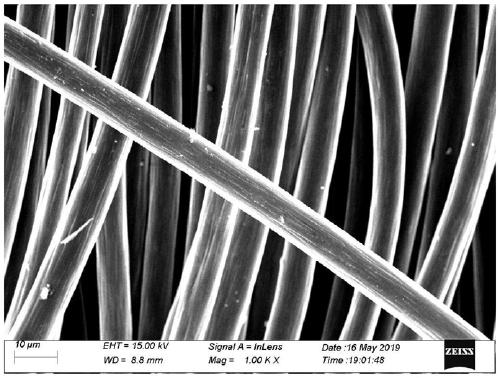

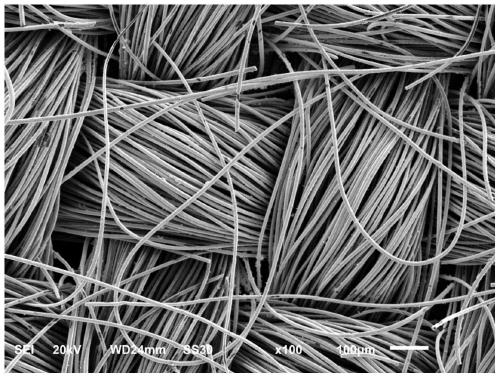

[0036] Magnetron sputtering is used to sputter a zinc oxide seed layer on the surface of the conductive carbon cloth to obtain a conductive carbon cloth with a zinc oxide seed layer;

[0037] Annealing the conductive carbon cloth with the zinc oxide seed layer to obtain annealed conductive carbon cloth;

[0038] The annealed conductive carbon is arranged in a precursor solution containing a zinc source, and subjected to hydrothermal treatment to obtain the carbon fiber-zinc oxide nanorod composite material.

[0039] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0040]The invention adopts magnetron sputtering to sputter a zinc oxide seed crystal layer on the surface of the conductive carbon cloth to obtain the conductive carbo...

Embodiment 1

[0058] The WOS1002 hydrophilic carbon cloth was heated up to 300°C at a heating rate of 10°C / s. After annealing for 20 minutes, it was washed with acetone and absolute ethanol for 20 minutes under ultrasonic conditions, and dried at 70°C for 30 minutes to obtain pretreatment. conductive carbon cloth;

[0059] The pretreated conductive carbon cloth is fixed on the magnetron sputtering disc, and the magnetron sputtering chamber is vacuumed. When the chamber vacuum reaches 5×10 -4 At Pa, turn on the power supply of the heating plate and set the temperature to 300°C, heat the carbon cloth substrate, set the gas flow meter to the cleaning mode to remove the residual gas in the pipeline, and then set the gas flow to 20 sccm and O respectively. 2 The flow rate was 10 sccm, and the gas was started to be introduced into the chamber. Adjust the manual gate valve to stabilize the pressure in the chamber at 2Pa, turn on the radio frequency power supply and adjust the radio frequency pow...

Embodiment 2

[0064] The WOS1002 hydrophilic carbon cloth was heated up to 300°C at a heating rate of 10°C / s. After annealing for 20 minutes, it was washed with acetone and absolute ethanol for 20 minutes under ultrasonic conditions, and dried at 70°C for 30 minutes to obtain pretreatment. conductive carbon cloth;

[0065] The pretreated conductive carbon cloth is fixed on the magnetron sputtering disc, and the magnetron sputtering chamber is vacuumed. When the chamber vacuum reaches 5×10 -4 At Pa, turn on the power supply of the heating plate and set the temperature to 300°C, heat the carbon cloth substrate, set the gas flow meter to the cleaning mode to remove the residual gas in the pipeline, and then set the gas flow to 20 sccm and O respectively. 2The flow rate was 10 sccm, and the gas was started to be introduced into the chamber. Adjust the manual gate valve to stabilize the pressure in the chamber at 2Pa, turn on the radio frequency power supply and adjust the radio frequency powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com