Flexible electrode fibrous membrane, flexible electrode plate, and manufacturing method and application thereof

A flexible electrode and manufacturing method technology, which is applied in the manufacture of hybrid/electric double layer capacitors, active material electrodes, electrode carriers/collectors, etc., can solve the capacity decay of energy storage devices, active materials, conductive agent binders, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

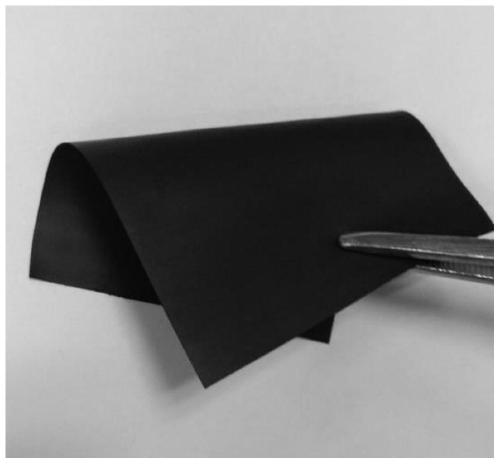

Image

Examples

Embodiment 1

[0043] The negative electrode sheet is produced through the following process:

[0044] Graphene, acetylene black, and polytetrafluoroethylene powder were mixed uniformly in a high-speed mixer in sequence according to the mass ratio of 90:2:8. Add isopropanol with a mass ratio of 200% to the above homogeneously mixed material, set the stirring speed of the high-speed mixer to 10000 rpm, and the time is 60 minutes to obtain a paste. Transfer the above paste to the screw extruder, the screw speed is 100rpm, and the heating temperature is 60°C; the material passes through the rotary propulsion device of the screw extruder and reaches the jetting die head of the slit drafting device, and is jetted into silk The hole diameter of the die head is 10μm, and the material is sprayed out from the spinneret hole to form a filament filled with fibrous thermoplastic binder, and then the filament is cooled and drawn by the airflow of the slit-type drafting device, and then reaches the convey...

Embodiment 2

[0048] The positive electrode sheet is produced through the following process:

[0049] Lithium iron phosphate, acetylene black, Ketjen black, and polytetrafluoroethylene powder were mixed in a high-speed mixer in sequence according to the mass ratio of 80:4:1:15. Add N-methylpyrrolidone with a mass ratio of 220% to the above homogeneously mixed materials, set the stirring speed of the high-speed mixer to 15000 rpm, and the time is 45 minutes to obtain a paste. Transfer the above paste to the screw extruder, the screw speed is 50rpm, and the heating temperature is 80°C; the material passes through the rotary propulsion device of the screw extruder and reaches the jet forming die head of the slit drafting device, and is sprayed into silk The hole diameter of the die head is 25μm, and the material is sprayed out from the spinneret hole to form a filament filled with fibrous thermoplastic binder, and then the filament is cooled and drawn by the airflow of the slit-type drafting d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com