Interconnected hollow nanostructures containing high capacity active materials for use in rechargeable batteries

A technology for active materials, nanostructures, applied at high surface areas. field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

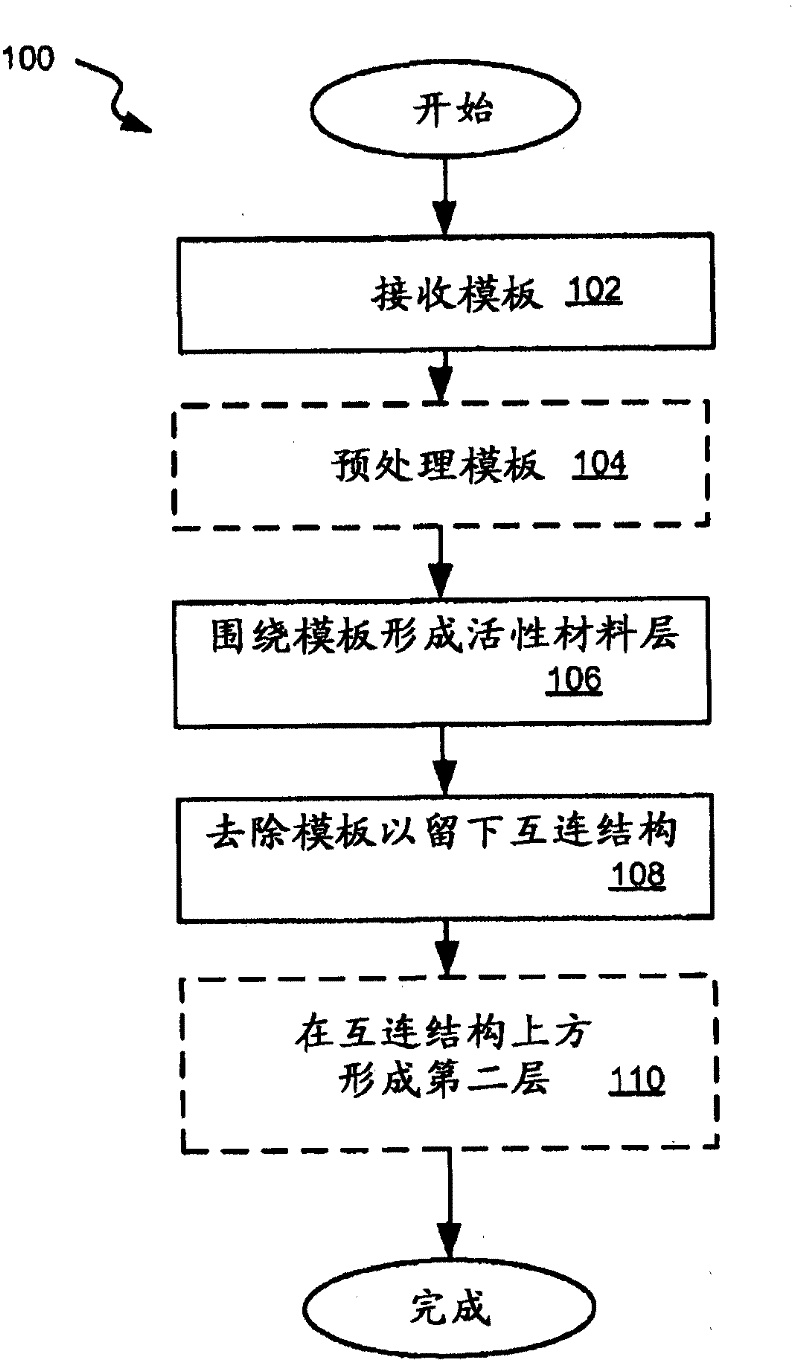

Method used

Image

Examples

example

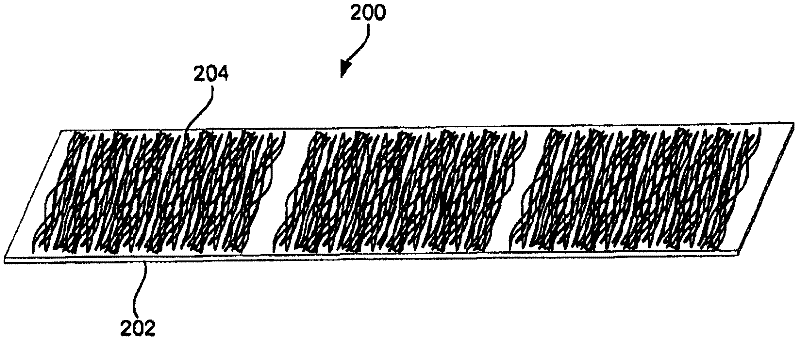

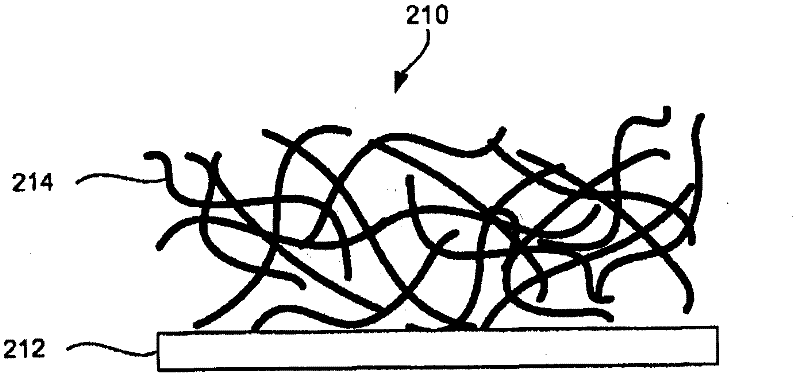

[0082] The above-described process can be used to prepare electrode layers of interconnected hollow nanostructures containing high-capacity active materials. Hollow nanostructures can have the shape of hollow spheres, tubes, or other shapes (regular and irregular). The cavity of the hollow nanostructure may have a maximum internal cross-sectional dimension (e.g., the inner diameter of a circular structure) of about 1 nanometer to 1000 nanometers, or, more specifically, about 5 nanometers to 500 nanometers, or even about 10 nanometers to 100 nanometers . The cavity provides free space for the active material to expand into without causing significant disturbance (eg, jostling) to other nanostructures or pulverization of the nanostructure itself. In particular embodiments, the cross-sectional dimensions and / or dimensions of the openings of some or all of the hollow nanostructures (e.g., at least about 50% of them) in the hollow cavities are critical for electrolyte infiltration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com