Preparation method of nitrogen and oxygen co-doped carbon nanofiber material, product and application

A carbon nanofiber and co-doping technology, which is applied in the field of nanomaterials, can solve the problems of time-consuming, complicated preparation methods, restrictions on the commercial application of nitrogen and oxygen co-doped carbon nanofiber materials, and achieve simplified preparation methods and shapes. The effect of uniform appearance and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

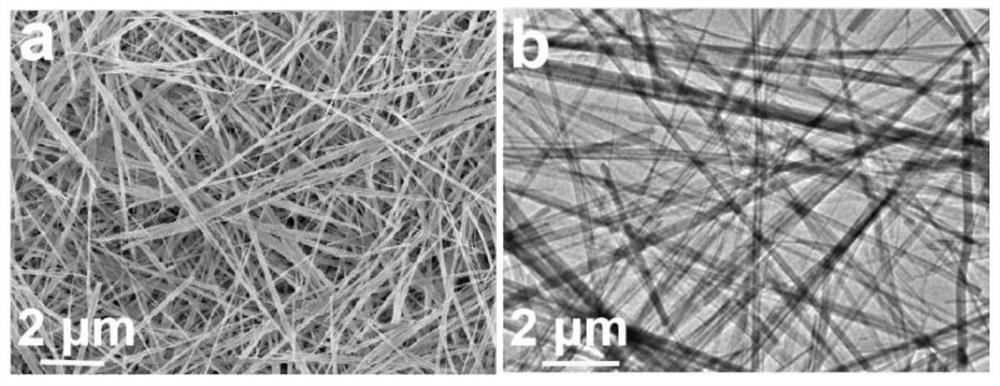

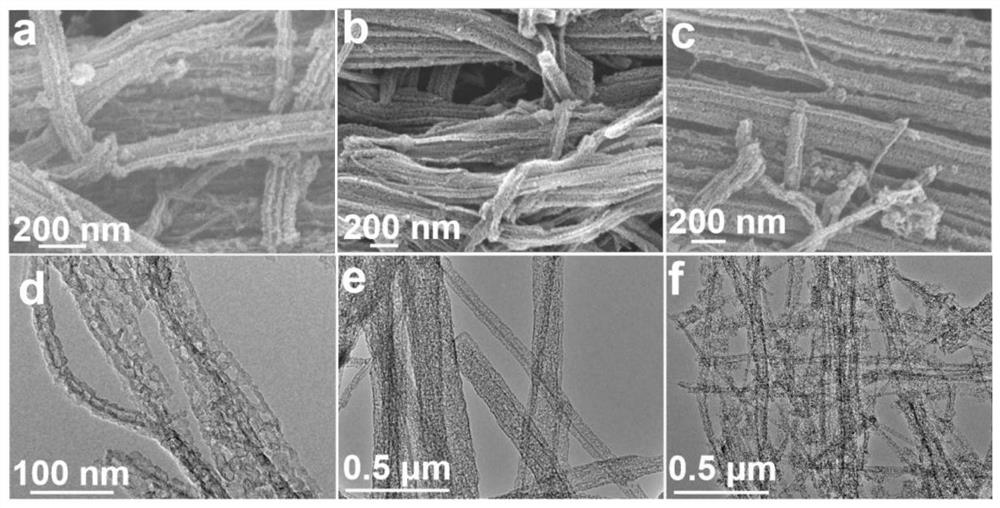

[0052] The preparation of nitrogen and oxygen co-doped carbon nanofiber material specifically comprises the following steps:

[0053] (1) At room temperature, add 1.2 g of manganese chloride and 0.9 g of nitrilotriacetic acid into 30 mL of isopropanol, stir magnetically for 10 minutes, then add 10 mL of deionized water and stir magnetically for 30 minutes to form Clear solution. The above solution was transferred to a 50mL stainless steel reaction kettle and sealed. The reaction kettle was placed in an oven, heated at 180°C for 6 hours, washed with water and ethanol three times, and dried in an oven at 60°C for 6 hours to obtain a white precursor.

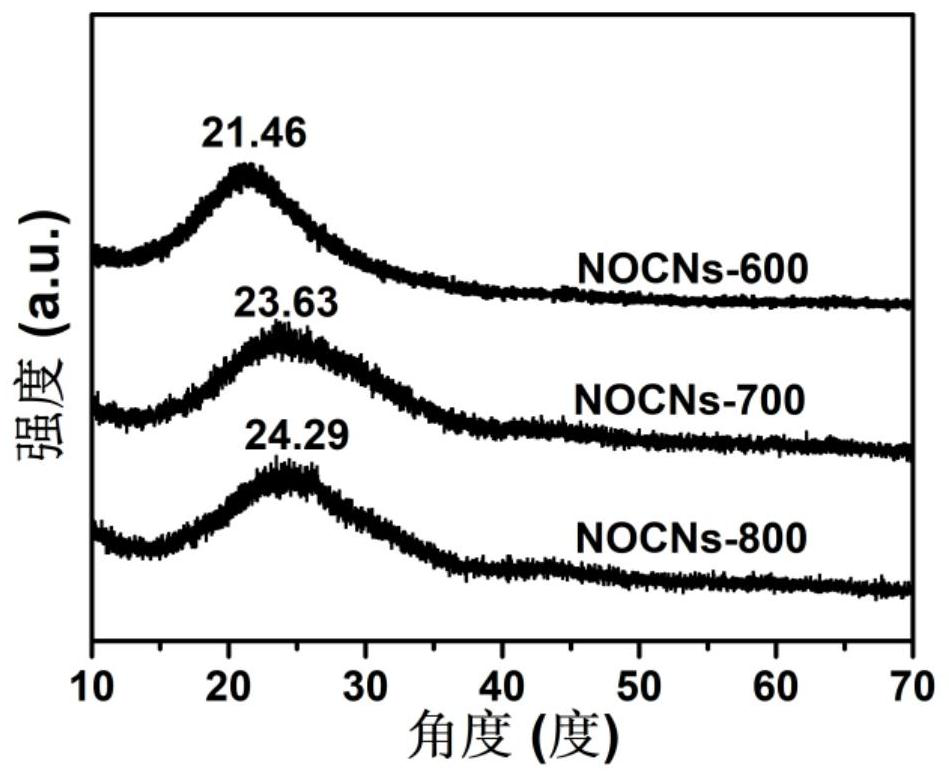

[0054] (2) The above precursors were then placed in a tube furnace fed with nitrogen, calcined at 600°C, 700°C and 800°C for 2 hours, and cooled naturally to room temperature to prepare ultrafine MnO nanoparticles embedded with nitrogen-doped porous carbon. crystal (MnO@NC), finally, the dried sample was etched with 3mol / L hydroc...

Embodiment 2

[0063] Adopt the nitrogen and oxygen co-doped carbon nanofiber material in embodiment 1 to prepare potassium ion battery negative electrode material, specifically comprise the following steps:

[0064] Mix nitrogen and oxygen co-doped carbon nanofiber materials with acetylene black and polyvinylidene fluoride PVDF in a mass ratio of 80:10:10 to make a slurry, and then coat the slurry on a copper foil at 80°C After drying in a special oven, the copper foil is cut into a circular electrode sheet with a diameter of 14mm, which is the negative electrode material of the lithium-ion battery.

Embodiment 3

[0066] Potassium ion battery is prepared by adopting the negative electrode material of potassium ion battery in Example 2, specifically comprising the following steps:

[0067] The electrode sheet in Example 1 is used as the positive electrode, and the circular metal potassium sheet with a diameter of 14mm is used as the negative electrode, and the mixture containing ethylene carbonate EC and diethyl carbonate DEC in a mass ratio of 1:1 is composed of A mixed solution of 3mol / L difluorosulfonimide potassium salt KFSI was used as the electrolyte, and a circular polypropylene film with a diameter of 16mm was used as a diaphragm, and a button cell was assembled in a glove box protected by an argon atmosphere as a test Battery.

[0068] Test it with a battery test system for a Neware BTS-610.

[0069] Determination result: if Figure 8 It is shown that at a current density of 100mA / g, after 200 cycles, the discharge capacity remains at 553.99mAh / g; as Figure 9 As shown, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com