Wire structure carbon fiber / MoS2 / MoO2 flexible electrode material and preparation method thereof

A flexible electrode and carbon fiber technology, used in microfiber electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of poor stability of molybdenum sulfide, fast energy decay, etc., to improve energy density and power density, improve stability and conductivity. properties, improved electrical conductivity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

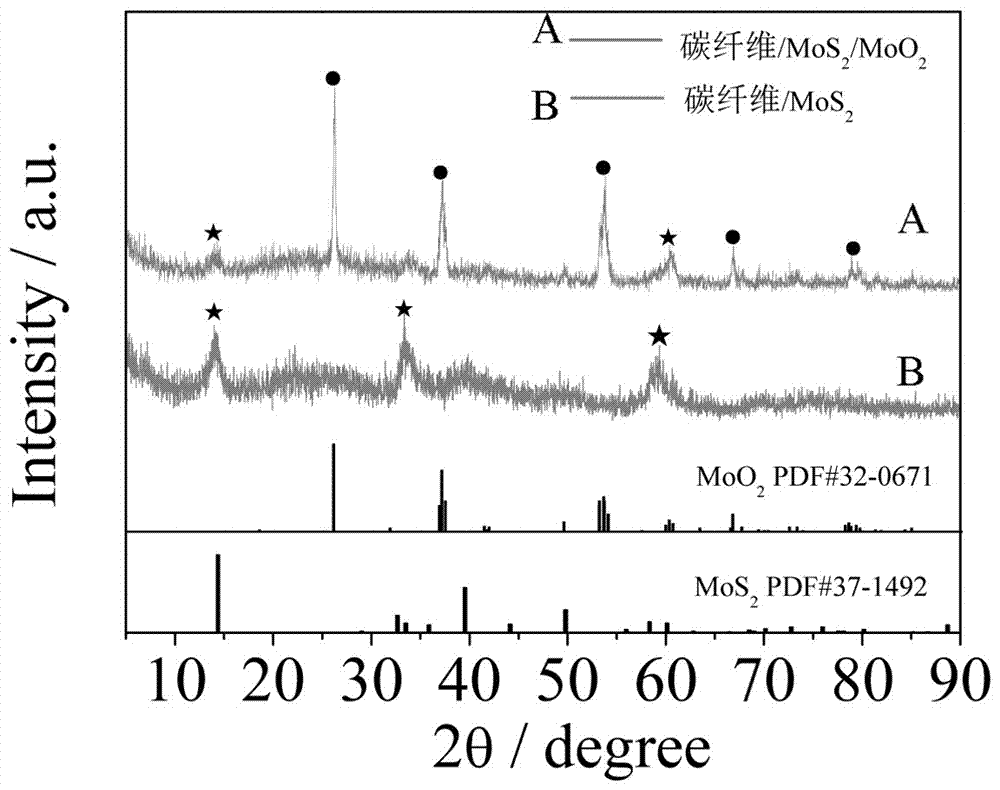

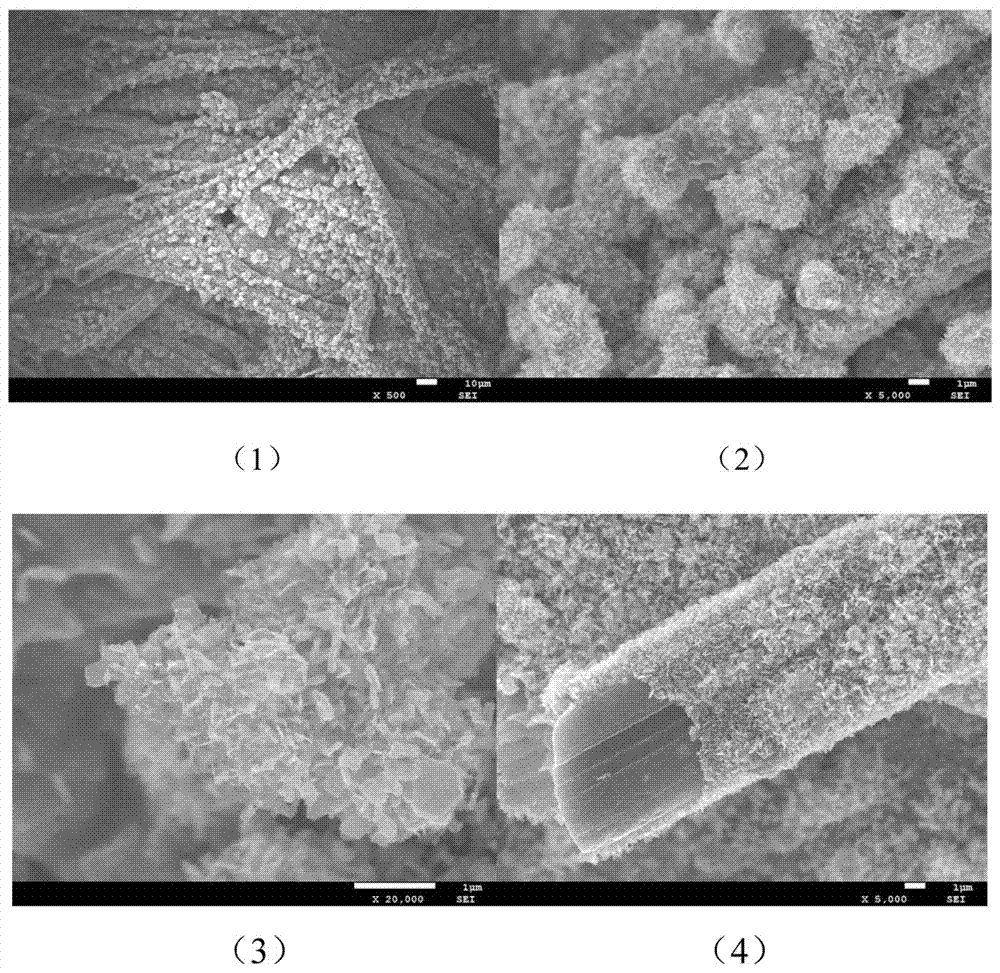

[0022] Example 1: Wire Structure Carbon Fiber / MoS 2 / MoO 2 Flexible electrode material Ⅰ

[0023] Wet paper towel in 1 mol L -1 Soak in dilute hydrochloric acid for 12 hours, then transfer the wet paper towel to a mixed solution of absolute ethanol / acetone with a volume ratio of 1:1 and soak for 6 hours, then wash the obtained wet paper towel with absolute ethanol and deionized water for 3-5 times , and then put it in a drying oven at 60°C for 12h to get the treated wet tissue and then calcined it in a tube furnace at 800°C for 4h, then put it in a hydrothermal kettle with 0.24g sodium molybdate and 0.76g thiourea 200 ℃ water heating for 24h. Formation of MoS from sodium molybdate and thiourea during hydrothermal process 2 Coated on the surface of carbon fiber to obtain flexible carbon fiber / MoS 2 flexible material. Finally, the material was calcined in oxygen at 500°C for 1 h at a low temperature to form a wire-structured carbon fiber / MoS 2 / MoO 2 Flexible electrode m...

Embodiment 2

[0024] Example 2 Wire Structure Carbon Fiber / MoS 2 / MoO 2 Flexible electrode material Ⅱ

[0025] Wet paper towel in 1 mol L -1 Soak in dilute hydrochloric acid for 12 hours, then transfer the wet paper towel to a mixed solution of absolute ethanol / acetone with a volume ratio of 1:1 and soak for 6 hours, then wash the obtained wet paper towel with absolute ethanol and deionized water for 3-5 times , and then dried in a 60°C drying oven for 12h. The treated wet tissue was calcined in a tube furnace at 800°C for 4h, and then placed in a hydrothermal kettle with 0.24g sodium molybdate and 0.76g thiourea in 200°C water Heat for 24 hours. Formation of MoS from sodium molybdate and thiourea during hydrothermal process 2 Coated on the surface of carbon fiber to obtain flexible carbon fiber / MoS 2 flexible material. The material was then calcined at 600 °C for 1 h in oxygen to form a wire-structured carbon fiber / MoS 2 / MoO 2 Flexible electrode material. The electrode material t...

Embodiment 3

[0026] Example 3 Wire Structure Carbon Fiber / MoS 2 / MoO 2 Flexible Electrode MaterialsⅢ

[0027] Put wet paper towel in 1mol L -1 Soak in dilute hydrochloric acid for 12 hours, then transfer the wet paper towel to a mixed solution of absolute ethanol / acetone with a volume ratio of 1:1 and soak for 6 hours, then wash the obtained wet paper towel with absolute ethanol and deionized water for 3-5 times , and then put it in a drying oven at 60°C for 12h to get the treated wet tissue and then calcined it in a tube furnace at 800°C for 4h, then put it in a hydrothermal kettle with 0.24g sodium molybdate and 0.76g thiourea 200 ℃ water heating for 24h. Formation of MoS from sodium molybdate and thiourea during hydrothermal process 2 Coated on the surface of carbon fiber to obtain flexible carbon fiber / MoS 2 flexible material. The material was then calcined at 400 °C in oxygen for 1 h to form a wire-structured carbon fiber / MoS 2 / MoO 2 Flexible electrode material. The electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com