Preparation method and application of transition metal sulfide/nitrogen-sulfur co-doped carbon composite fiber electrode material

A nitrogen-sulfur co-doping, transition metal technology, applied in microscopic fiber electrodes, active material electrodes, nanotechnology for materials and surface science, etc. Complex problems, etc., to achieve excellent electrochemical performance, ease volume expansion, and strong applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

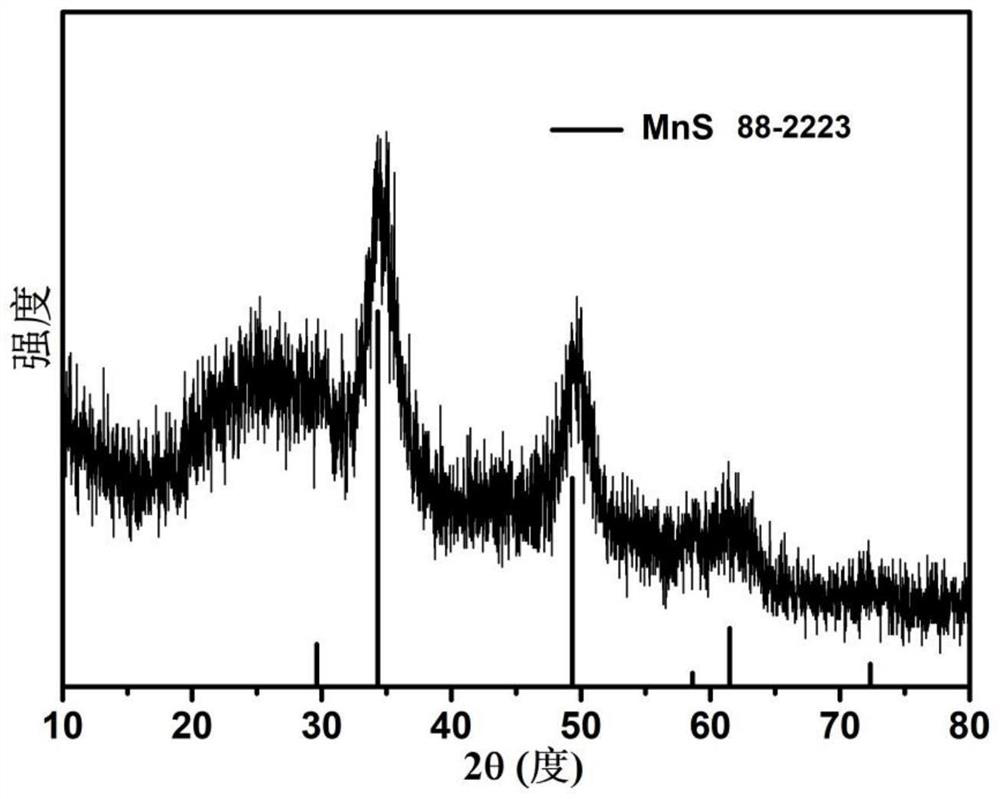

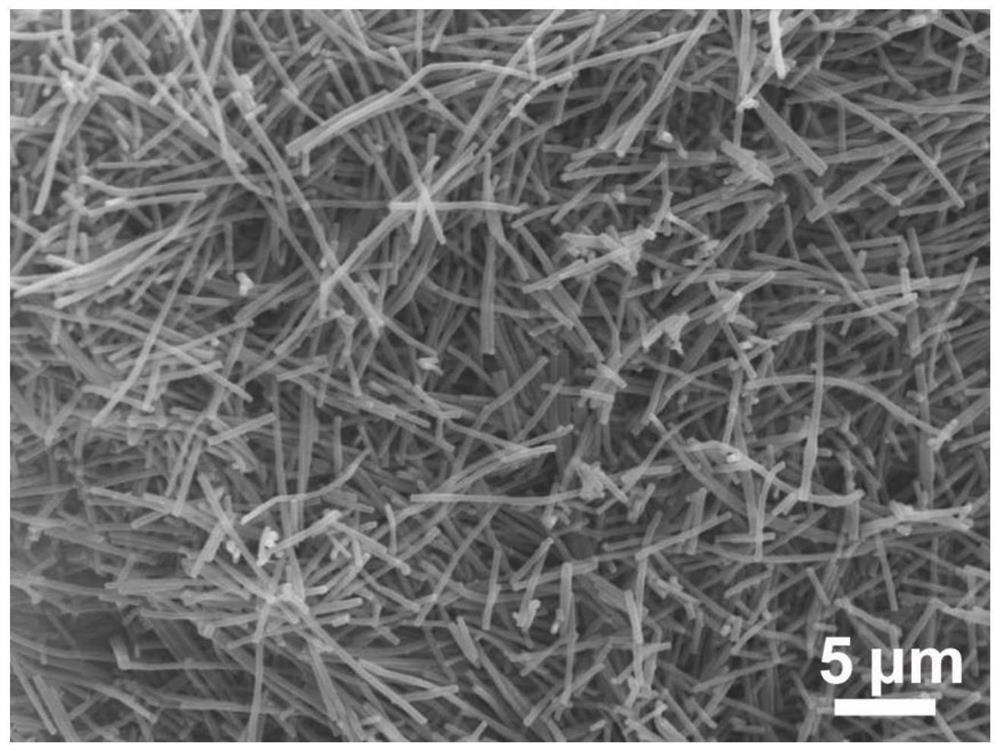

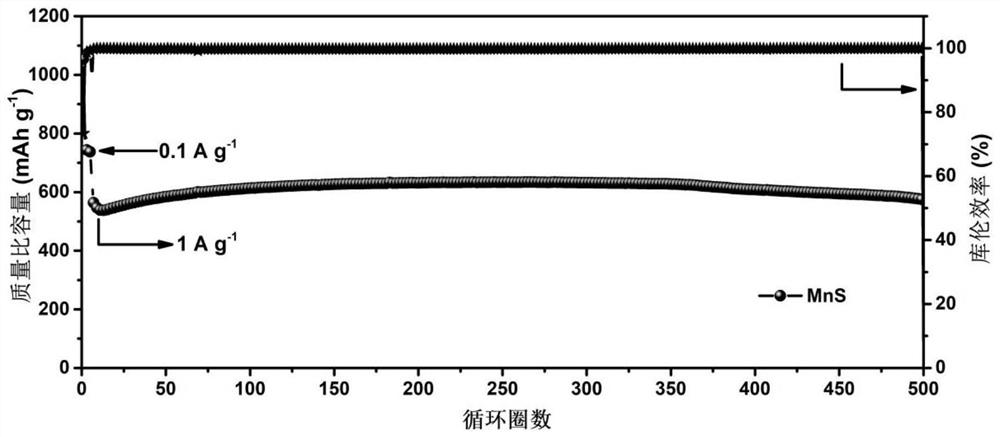

Embodiment 1

[0037] The first step is the preparation of electrospinning solution, the specific steps are as follows:

[0038] Dissolve 0.253g of manganese acetylacetonate (0.001mol) in 2mL (1.89g) of N,N-dimethylformamide, then add 0.192g (0.006mol) of sulfur powder and stir at 50°C until the reaction is complete, and finally Add 0.12 g of polyacrylonitrile (Mw=150000) and stir until completely dissolved to form a uniform and viscous spinning solution.

[0039] Second step is the preparation of polyacrylonitrile fiber, concrete steps are as follows:

[0040] Take 2mL of the prepared spinning solution and place it in the electrospinning device (Yunfan DP30 basic type), set the spinning voltage to 10kV, the receiving distance to 15cm, the inner diameter of the electrospinning needle to 0.6mm, and the flow rate of the spinning solution to 1mL / h, collect the fiber cloth received on the aluminum foil for later use.

[0041] The third step is the pre-oxidation and carbonization of polyacrylo...

Embodiment 2

[0045] The first step is the preparation of electrospinning solution, the specific steps are as follows:

[0046] Dissolve 0.263g of zinc acetylacetonate in 2mL of N,N-dimethylformamide solution, then add 0.128g of sulfur powder and stir at 50°C until the reaction is complete, and finally add 0.12g of polyacrylonitrile (Mw=150000) Stir until completely dissolved to form a uniform viscous spinning solution.

[0047] Second step is the preparation of polyacrylonitrile fiber, concrete steps are as follows:

[0048] Take 2mL of the prepared spinning solution and place it in the electrospinning device, set the spinning voltage to 10kV, the receiving distance to 15cm, the inner diameter of the electrospinning needle to 0.51mm, and the flow rate of the spinning solution to 1.5mL / h. The received fibers are collected for later use.

[0049] The third step is the pre-oxidation and carbonization of polyacrylonitrile fibers, the specific steps are:

[0050] The obtained polyacrylonitri...

Embodiment 3

[0053] The first step is the preparation of electrospinning solution, the specific steps are as follows:

[0054] Dissolve 0.256g of nickel acetylacetonate in 2mL of N,N-dimethylformamide solution, then add 0.128g of sulfur powder and stir at 50°C until the reaction is complete, and finally add 0.12g of polyacrylonitrile (Mw=150000) Stir until completely dissolved to form a uniform viscous spinning solution.

[0055] Second step is the preparation of polyacrylonitrile fiber, concrete steps are as follows:

[0056] Take 2mL of the prepared spinning solution and place it in the electrospinning device, set the spinning voltage to 10kV, the receiving distance to 15cm, the inner diameter of the electrospinning needle to 0.6mm, and the flow rate of the spinning solution to 1mL / h. The fibers are collected for later use.

[0057] The third step is the pre-oxidation and carbonization of polyacrylonitrile fibers, the specific steps are:

[0058] The obtained polyacrylonitrile fibers ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com