Non-noble metal catalyst for oxygen reduction, and preparation and application of catalyst

A non-precious metal, catalyst technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of easy-to-collapse graphene rearrangement, and achieve rich pore structure, good mass transfer performance, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

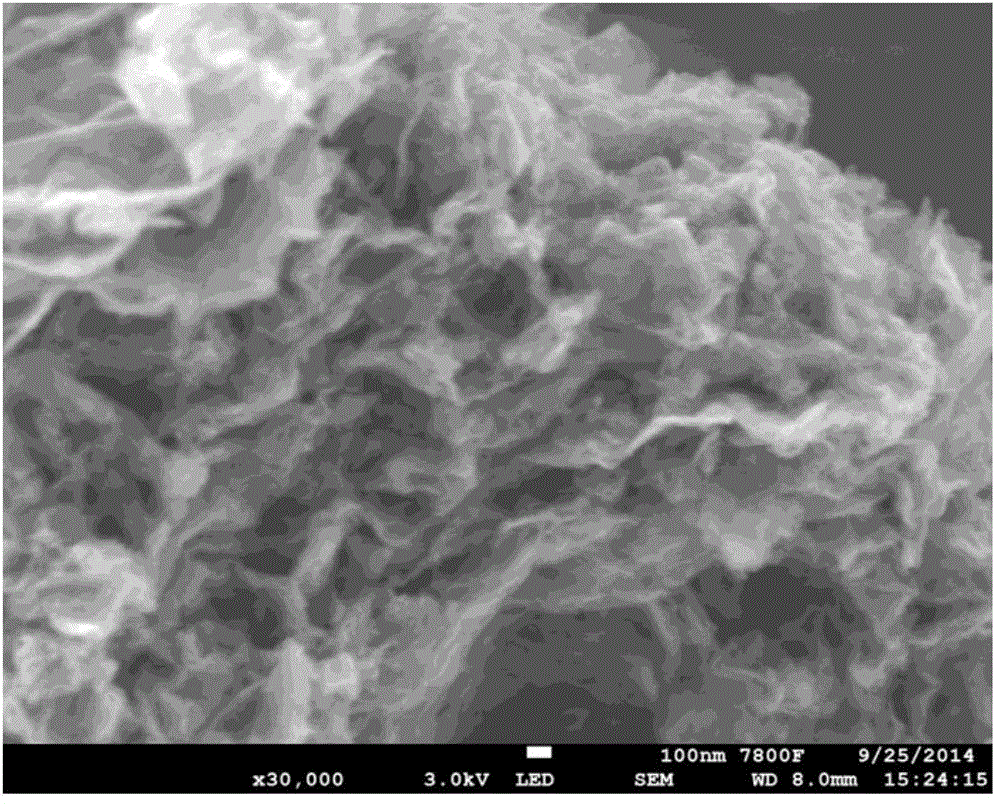

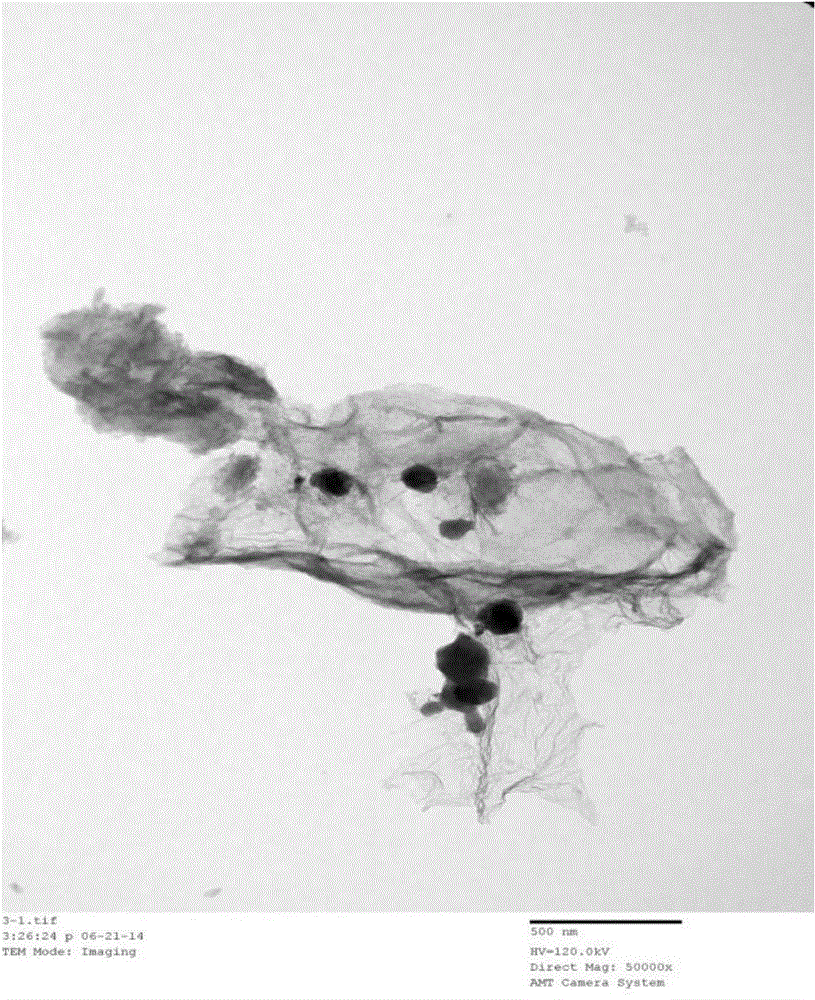

[0034] Example 1: 50 mg of graphite oxide was dispersed in 100 mL of water, ultrasonicated for 4 hours to obtain a uniform graphite oxide solution, 26.8 mg of hexahydrate and ferric chloride were added, ultrasonicated for 1 hour, left standing for 24 hours, and 277.5 mg of 5% Solution and 0.25mL aniline, stirred at 5°C for 1h, added 0.6257g ammonium persulfate, stirred at 5°C for 36h, evaporated the solvent at 90°C to make the solid content to 5%, freeze-dried for 48h, and obtained airgel. Put the airgel in a quartz boat, raise the temperature to 900°C at 5°C / min under the protection of nitrogen, keep it warm for 1h, cool naturally, then treat it in 0.5mol / L sulfuric acid solution at 80°C for 6h, wash and dry, and then Put it in a quartz boat for the first time and raise the temperature to 900°C at 5°C / min under the protection of nitrogen, keep it warm for 3h, and cool naturally to obtain a non-precious metal oxygen reduction catalyst.

[0035] Weigh the catalyst 5mg of the g...

Embodiment 2

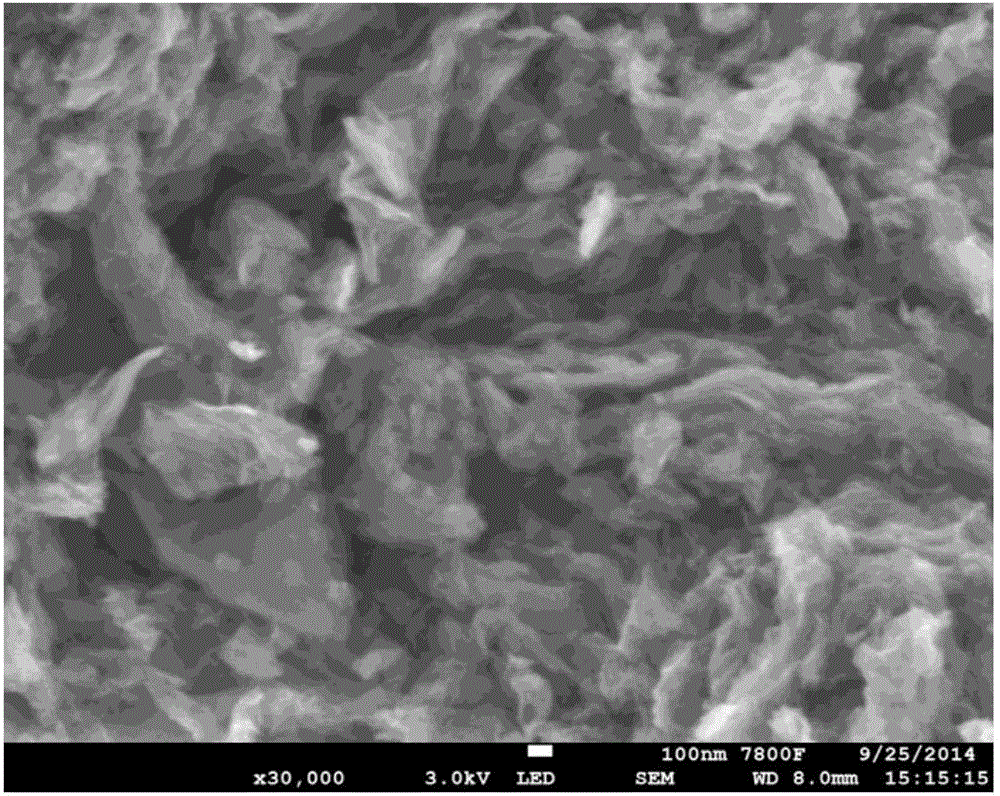

[0036] Embodiment 2: added 5% The amount of the solution is 1.11g, and all the other conditions are the same as in Example 1.

Embodiment 3

[0037] Embodiment 3: added 5% The amount of the solution is 3.33g, and all the other conditions are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com