Preparation method of auto-doped carbon catalysis material based on activated sludge domestication

An activated sludge and self-doping technology, applied in biochemical fuel cells, electrical components, battery electrodes, etc., can solve the problems of difficult disposal and utilization of activated sludge, secondary pollution, etc., and achieve aerobic reduction catalytic performance, cycle The effects of stability, poisoning resistance, and strong electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

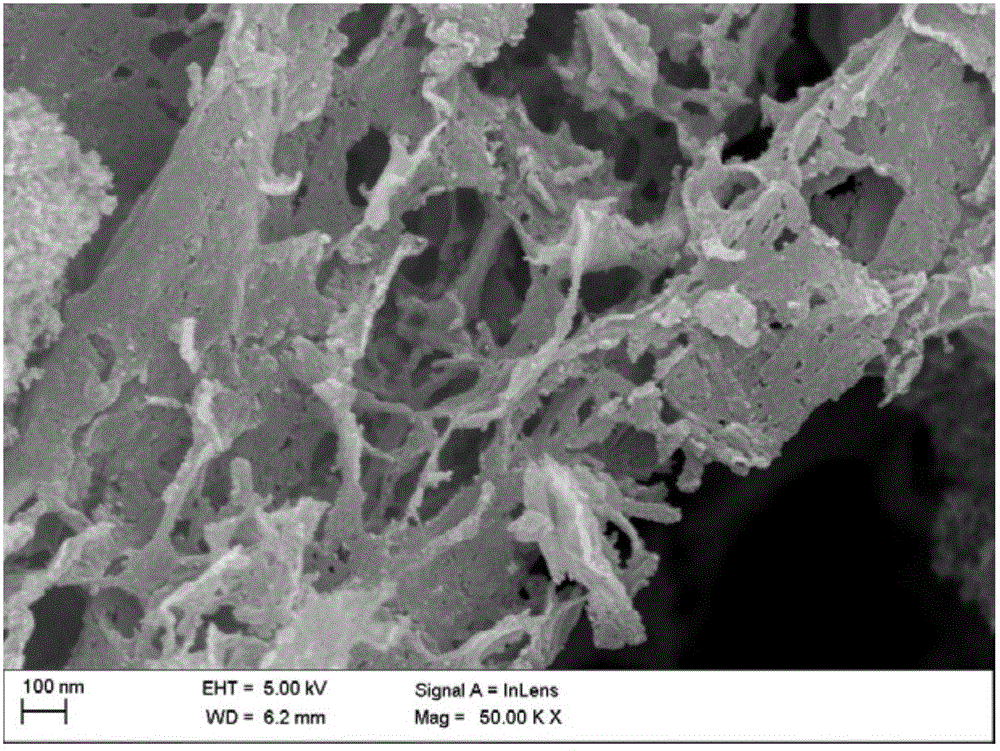

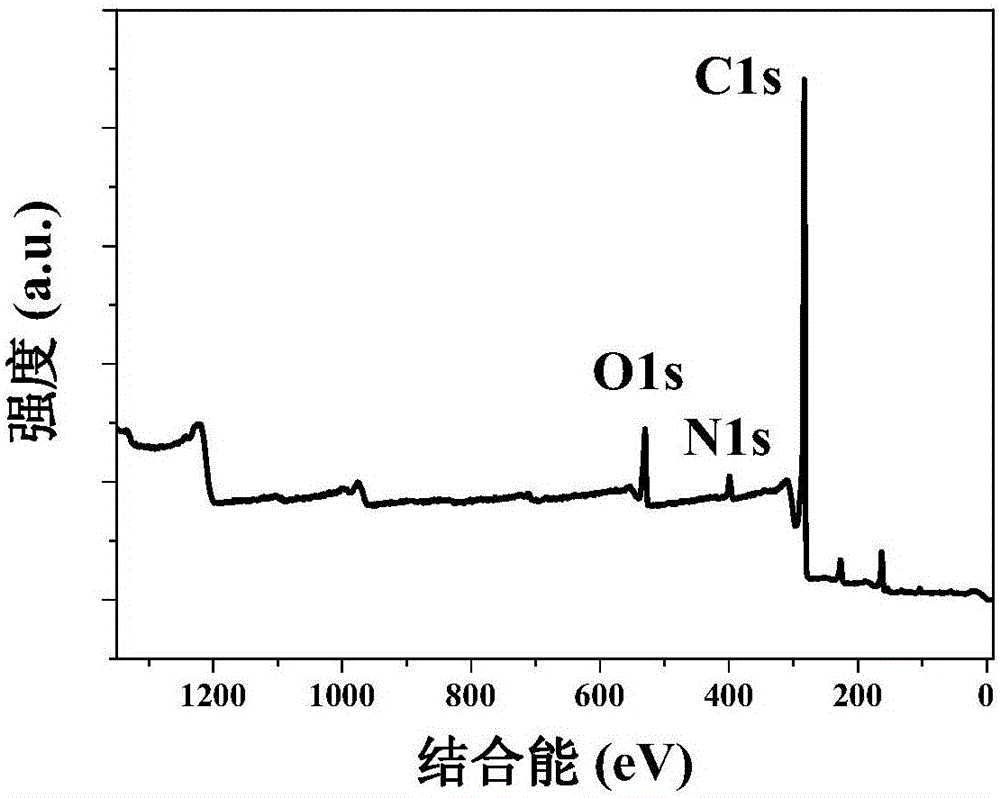

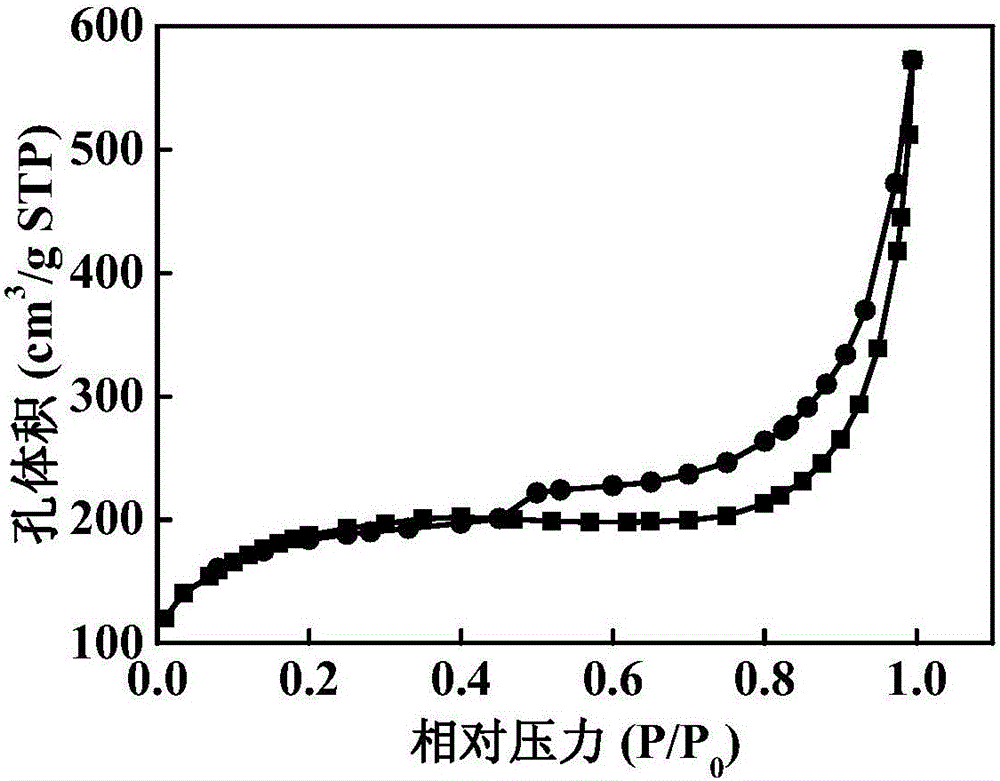

[0046] Get 10 grams of nitrification domesticated autotrophic activated sludge (the mass percentage of carbon element in this sludge is 23.04%, the mass percentage of nitrogen element is 6.39%, oxygen element The mass percentage is 28.56%) and dried at 60°C for 6 hours, taken out, ground, passed through a 100-mesh sieve, and then calcined at 800°C for 2 hours under a nitrogen atmosphere at a heating rate of 10°C per minute. The powder is treated with hydrochloric acid, washed with distilled water until neutral, dried at 60°C and passed through a 300-mesh sieve to obtain a self-doped porous sludge carbon material powder, that is, a self-doped carbon catalytic material.

[0047] The nitrification acclimation is specifically:

[0048] The activated sludge is in the nitrification acclimation solution, and the air flow rate is 1-3L / min for aerobic acclimatization and cultivation, and the MLSS is controlled at 3-6g / L to obtain autotrophic activated sludge floes with nitrifying bacte...

Embodiment 2

[0067] Get 10 grams of phenol domestication heterotrophic activated sludge (the mass percentage of carbon element in this sludge is 24.06%, the mass percentage of nitrogen element is 4.72%, oxygen element The mass percentage is 29.16%) and dried at 60°C for 6 hours, taken out, ground, passed through a 100-mesh sieve, and then calcined at 800°C for 2 hours under a nitrogen atmosphere at a heating rate of 5°C per minute, and treated with hydrochloric acid Afterwards, it was washed with distilled water until neutral, dried at 60° C. and passed through a 300-mesh sieve to obtain a self-doping porous sludge carbon material powder, that is, a self-doping carbon catalytic material.

[0068] The phenol domestication of the present embodiment is specifically:

[0069] The activated sludge is in the phenol acclimation solution, and the air flow rate is 1-3L / min for aerobic acclimatization culture; the MLSS is controlled at 3-6g / L; the heterotrophic activated sludge floes with phenol-deg...

Embodiment 3

[0076] Get 10 grams of the nitrification acclimation self-supporting type activated sludge (the mass percent of nitrogen element in this sludge is 6.39%, the mass percent of oxygen element is 28.56%) by the nitrification and acclimation autotrophic activated sludge of aerobic pool sludge domestication and cultivation of Shaogang coking waste water project in 60 Dry at ℃ for 6 hours, take it out, grind it, pass through a 100-mesh sieve, and then calcinate at 900℃ for 2 hours under nitrogen atmosphere at a heating rate of 10 degrees Celsius per minute, wash with distilled water until neutral after being treated with hydrochloric acid, and then After drying at 60°C, pass through a 300-mesh sieve to obtain a self-doping porous sludge carbon material powder, that is, a self-doping carbon catalytic material.

[0077] Subsequent experimental conditions are the same as in Example 1, and the CV scanning results are as follows: Figure 9 It is shown that it has excellent oxygen reductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com