Preparation method of covalent organic framework material derivative carbon skeleton loaded metallic monatomic composite material

A covalent organic framework and metal-loaded technology, which is applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that metal active components are easy to aggregate into nanoparticles, The types of single-atom metals cover a narrow range of problems, such as single atoms are easy to fall off from the carrier, and the reaction process conditions are easy to control, the synthesis time is short, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

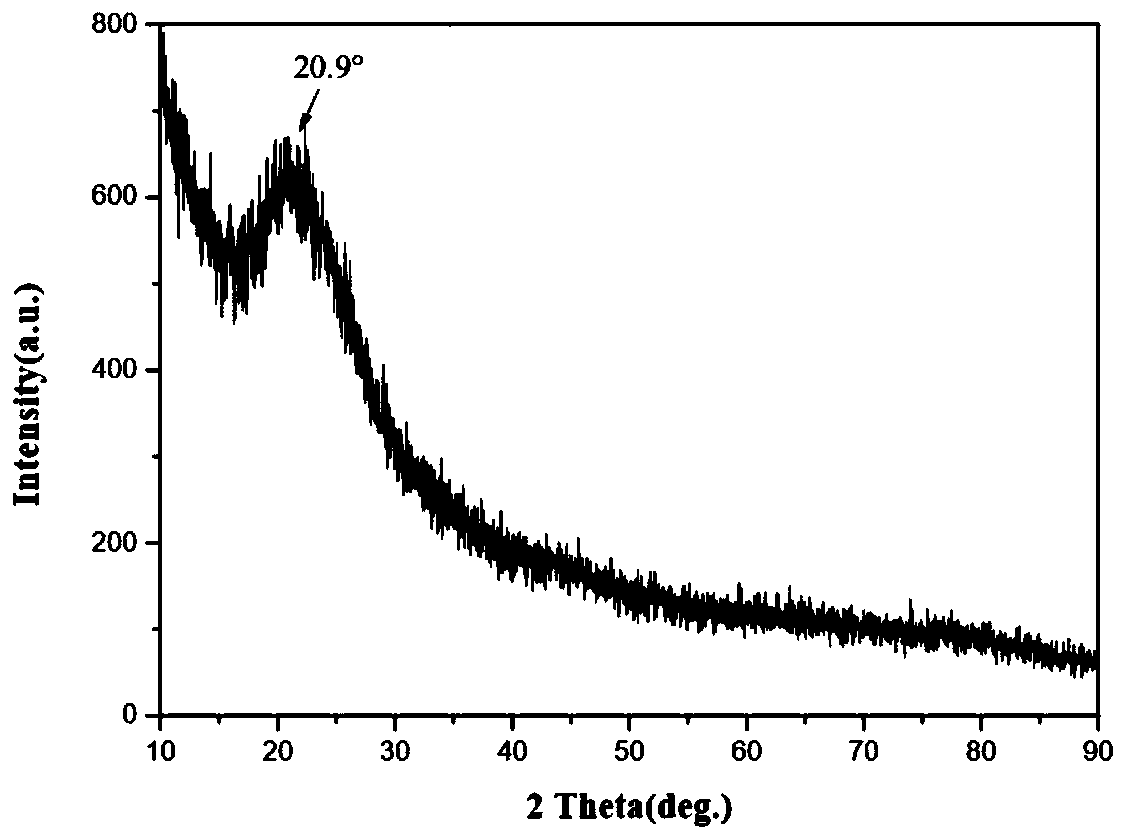

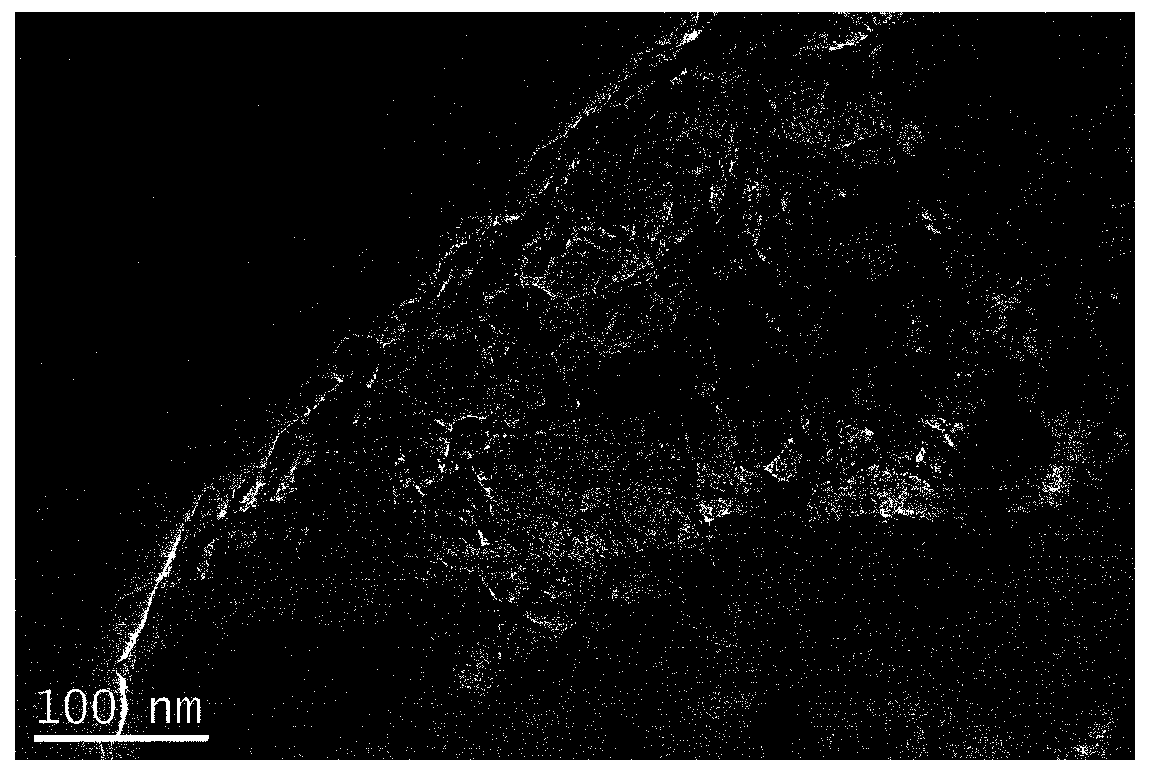

[0027] Preparation of Fe@COFs-2-700 Fe@COFs-2-700, a covalent organic framework material-derived carbon skeleton-loaded single-atom iron composite:

[0028] Step 1: Weigh 32mg of p-phenylenediamine (0.3mmol) and 95mg of 2,4,6-triformylphloroglucinol (0.45mmol), place them in a mortar and grind them evenly, then add 2 drops of 1,3,5-Trimethylbenzene, dioxane and acetic acid in a volume ratio of 1:1:0.01 mixed solution, continue to grind evenly; the obtained product is centrifuged and cleaned 3 times with dichloromethane as a solvent (centrifuge speed is 2500r / min, each centrifugation time is set to 8min), then collected by methanol, and then dried in an oven at 60°C. The dried powder was placed in a tube furnace, heated to 180°C at a rate of 2°C / min under a nitrogen atmosphere with a flow rate of 0.1mL / min, and kept at a constant temperature for 24 hours; after the reaction was completed, it was cooled in a nitrogen atmosphere to At room temperature, the dark red target produ...

Embodiment 2

[0035] Preparation of Fe@COFs-1-700 Fe@COFs-1-700, a covalent organic framework material-derived carbon skeleton-loaded single-atom iron composite:

[0036] The preparation method of this embodiment is the same as that of Embodiment 1, the only difference is that 80 mg of anhydrous ferric chloride is weighed in step 2.

[0037] It has been demonstrated that in this example, monoatomic iron is uniformly dispersed in the carbon skeleton derived from the high-temperature carbonization of the covalent organic framework material, and the composite material has high dispersion of catalytic active sites and high catalytic stability.

Embodiment 3

[0039] Preparation of Fe@COFs-0.5-700 Fe@COFs-0.5-700, a covalent organic framework material-derived carbon skeleton-loaded single-atom iron composite:

[0040] The preparation method of this embodiment is the same as that of embodiment 1, the only difference is that step 2 weighs 40 mg of anhydrous ferric chloride.

[0041] It has been demonstrated that the monoatomic iron in this example is highly dispersed and stably embedded in the carbon skeleton derived from the covalent organic framework material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com