Patents

Literature

33results about How to "Facilitate the realization of industrial application" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

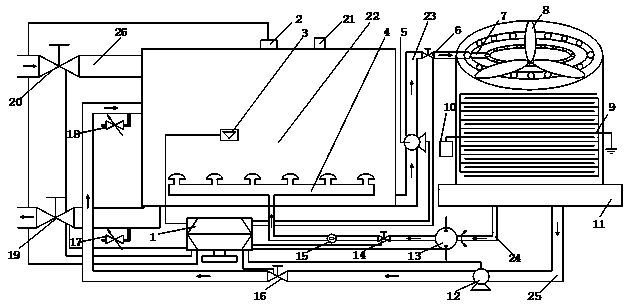

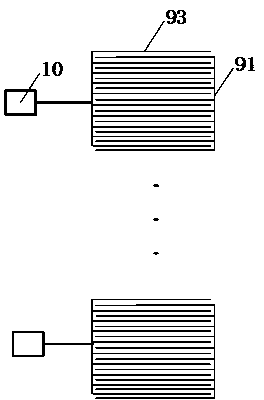

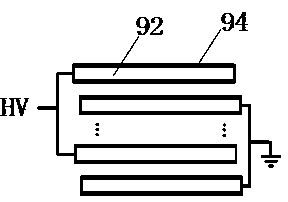

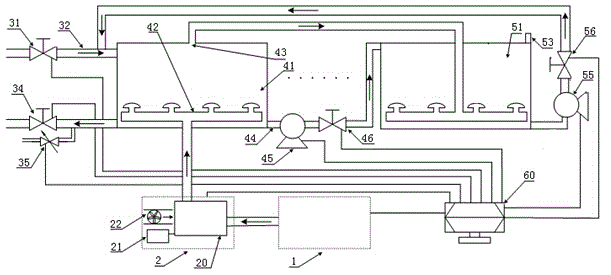

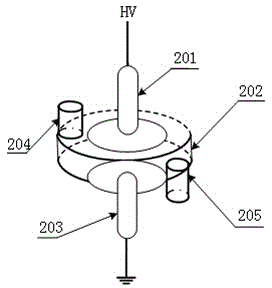

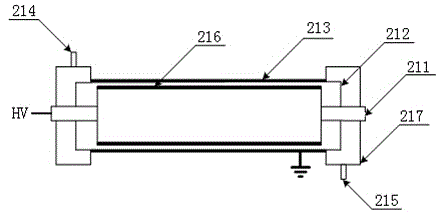

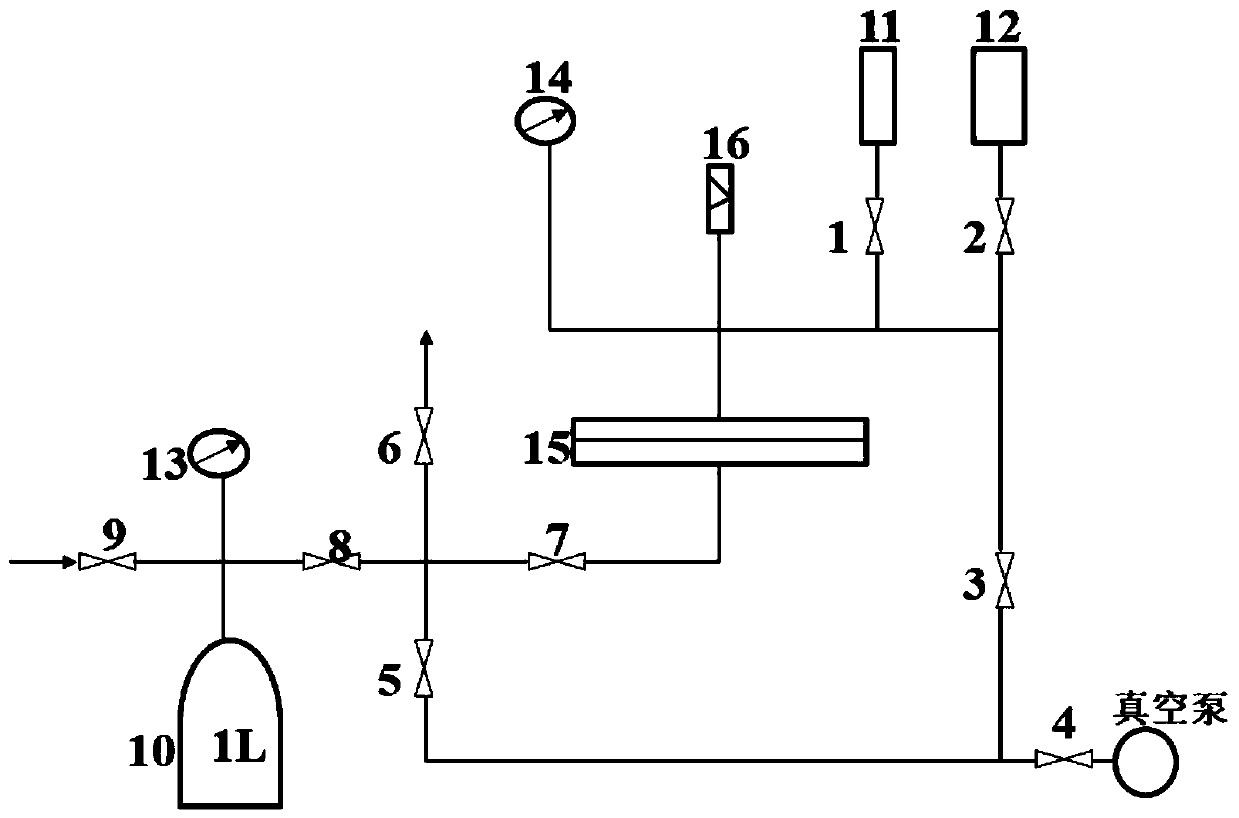

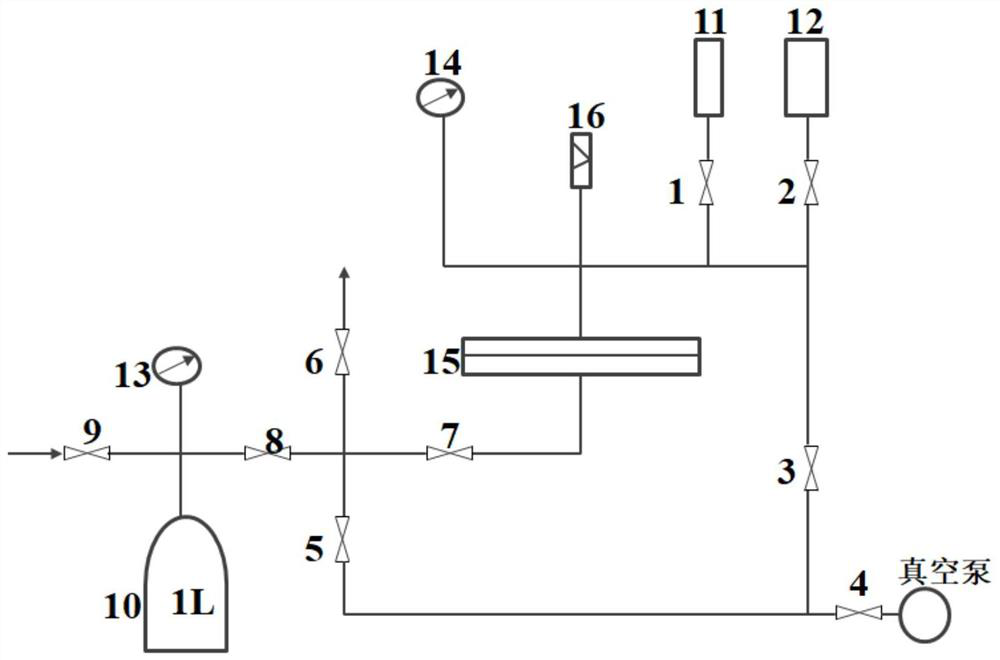

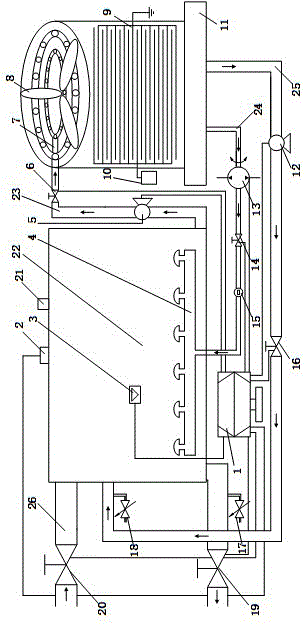

High-pressure atomizing dielectric barrier discharge plasma water treatment device

ActiveCN103693714AFully degradedImprove decomposition efficiencyWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationVapor–liquid separatorHigh pressure water

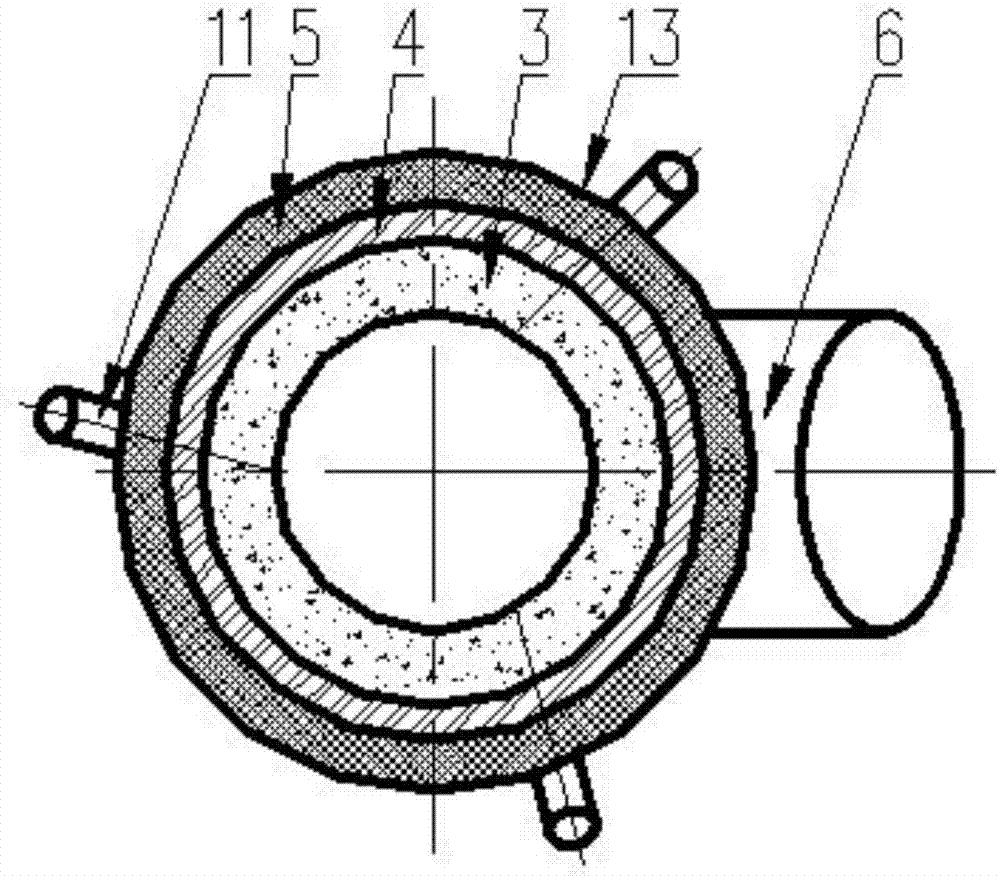

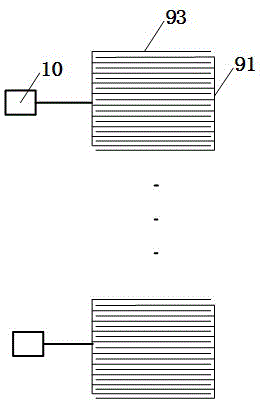

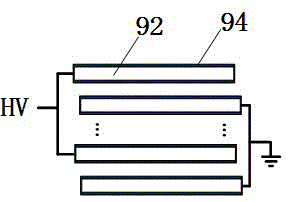

The invention relates to a high-pressure atomizing dielectric barrier discharge plasma water treatment device which comprises a sewage treatment cavity and a discharge reaction chamber, wherein a sewage outlet II is formed in the side wall of the sewage treatment cavity, and a dosing device for feeding ferrous sulfate into the sewage treatment cavity and a gas outlet are arranged in the top wall; the sewage outlet II is communicated with one end of a sewage pipe I; an array type high-pressure atomizing spray head is arranged at the other end of the sewage pipe I and positioned at the top of the discharge reaction chamber; a high-pressure water pump is arranged on the sewage pipe I; a fan for blowing the high-pressure atomized sewage into the discharge reaction chamber is arranged at the top of the discharge reaction chamber, and the bottom is communicated with a gas-liquid mixture inlet of a gas-liquid separator; the gas-state substance (mixture of air and ozone) and liquid-state substance (sewage and hydrogen peroxide) separated by the gas-liquid separator are fed into the sewage treatment cavity respectively. The device provided by the invention makes full use of the incomplete-reaction strong-oxidizing substances, increases the contact area between sewage and plasma, improves the sewage treatment efficiency and reduces the operation cost.

Owner:CHONGQING UNIV

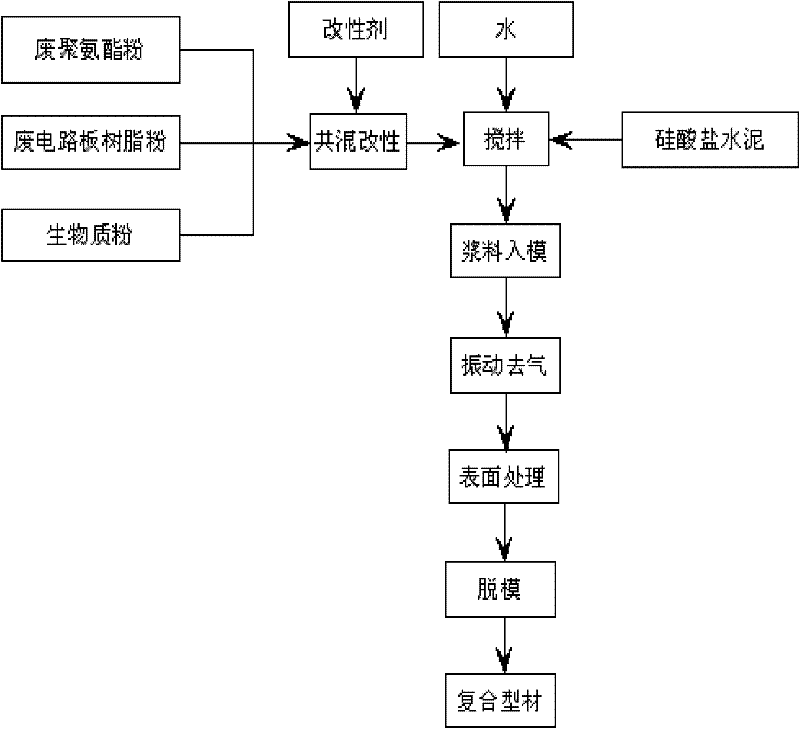

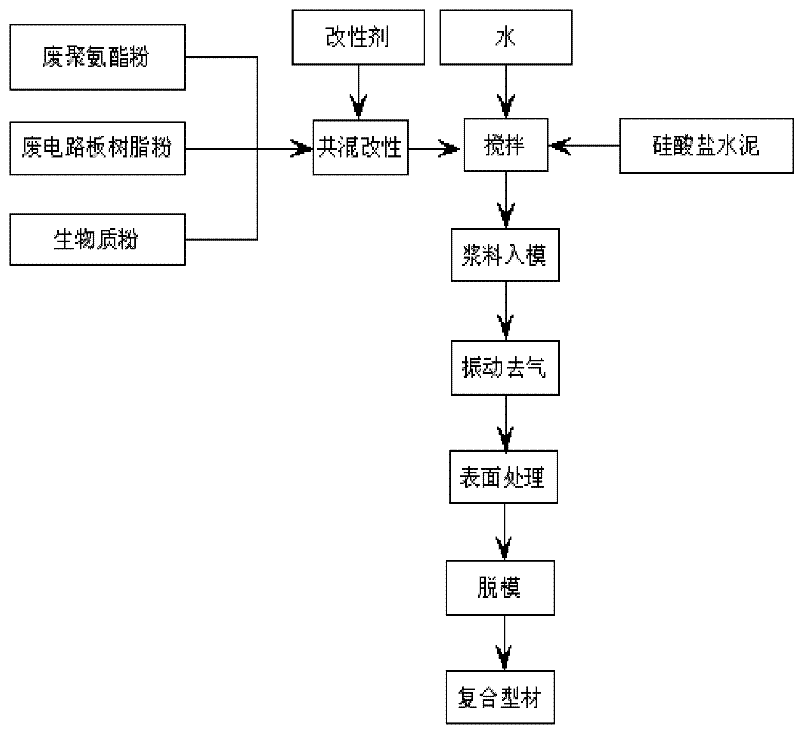

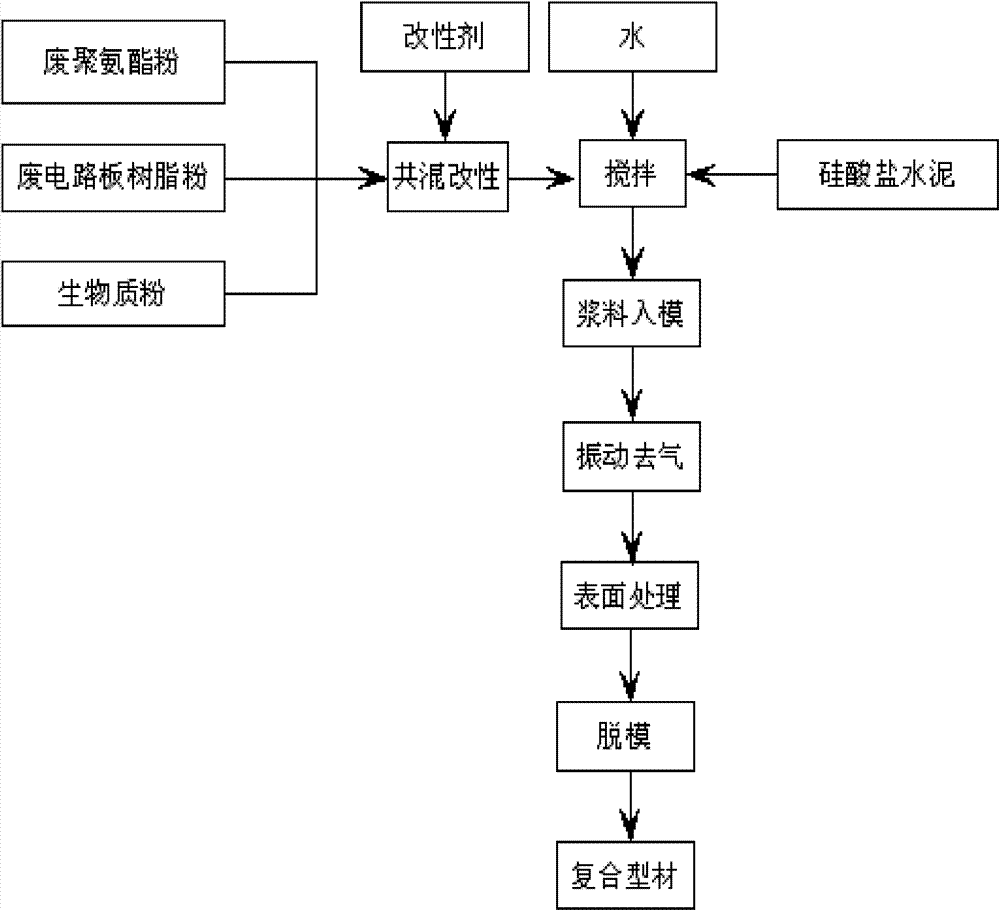

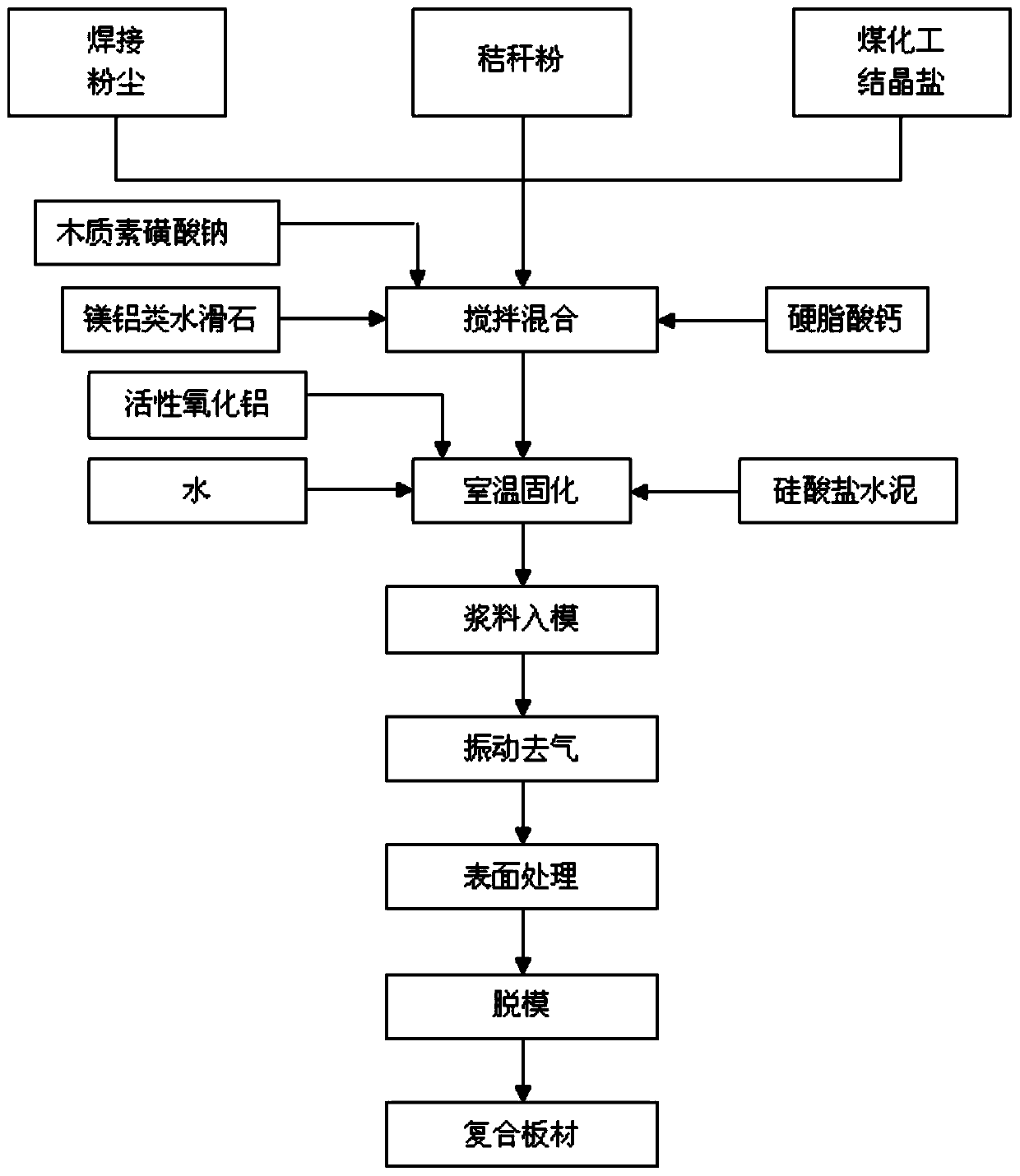

Manufacturing method of composite enhanced insulating section bar

The invention discloses a manufacturing method of a composite enhanced insulating section bar. According to the invention, with a modification technology and a room temperature solidification technology, waste circuit board resin powder, waste polyurethane powder and biomass powder are solidified into a section bar under room temperature. Specific steps of the method are that: after a sieving process, waste circuit board resin powder with a granularity range of 0.5 to 5mm, waste polyurethane powder with a granularity range of 1 to 20 mm, and biomass powder with a granularity range of 1 to 10mm are blended-modified, and cemented; the slurry is injected into a testing mold, and is shaped; the testing mold with injected slurry is placed on a vibrating machine to be vibrated for 1 to 5min, such that air bubbles are removed, and a hydro-thermal synthesizing reaction of the gel material is accelerated; the material is then processed through a surface treatment process that the surface of the slurry is flattened; the slurry is stood for 24 hours, and is demolded; the resulting material is dried, such that the composite enhanced section bar is obtained. According to the invention, no pollution is brought to the manufacturing processes. The technology is simple; the cost is low; the produced section bars have great application value; and low-carbon, environment protection and resource re-utilization are realized.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

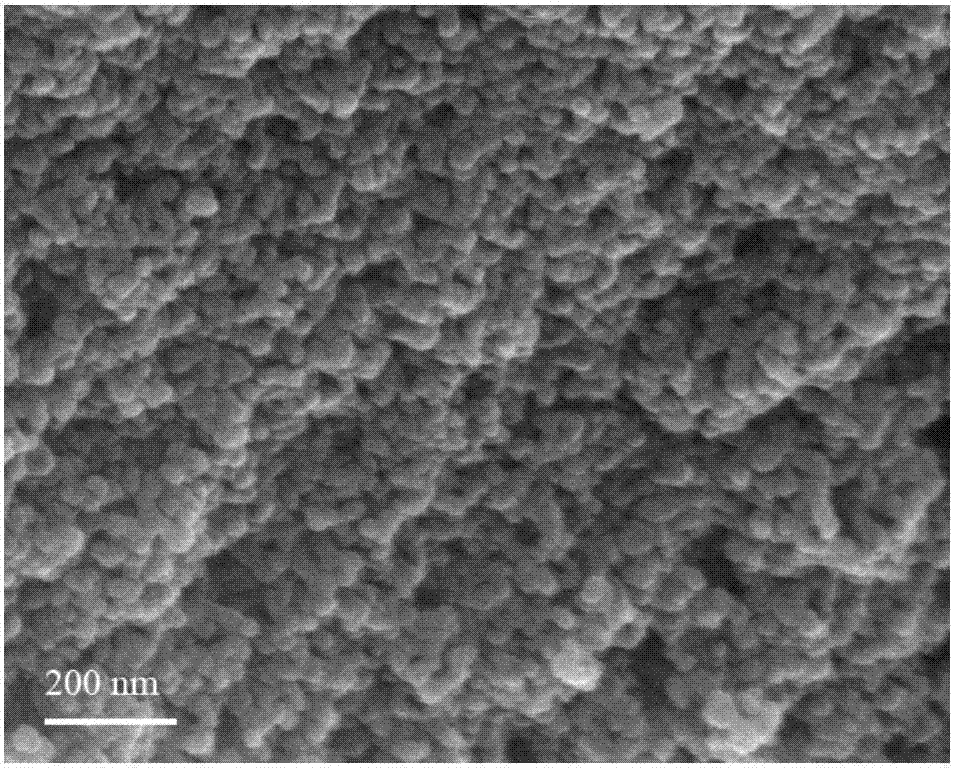

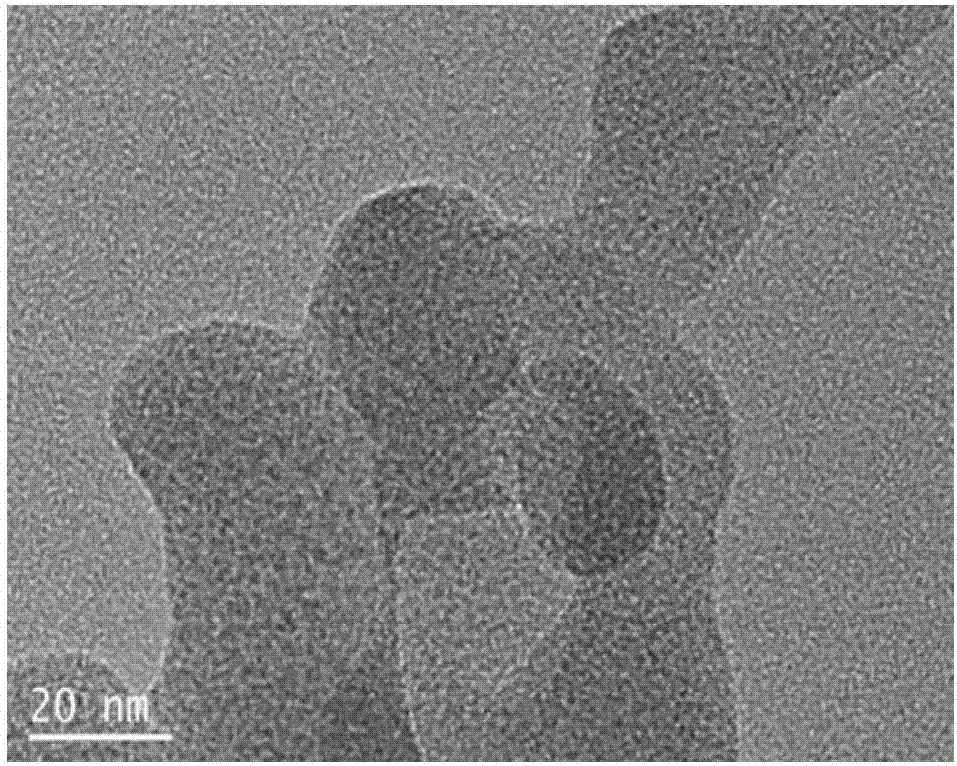

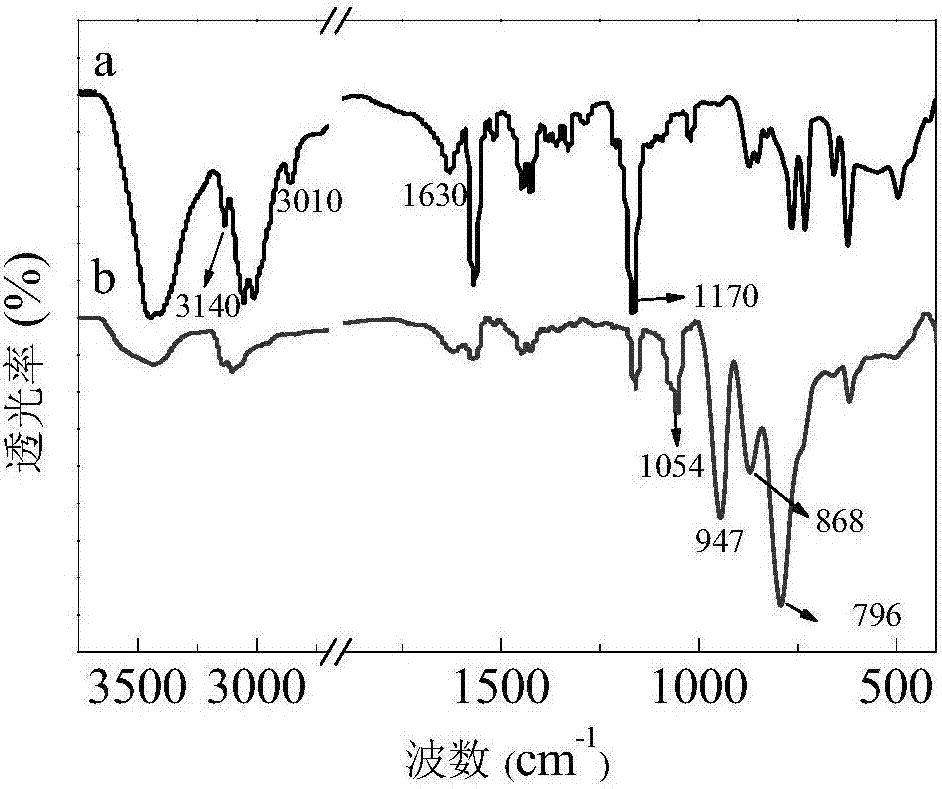

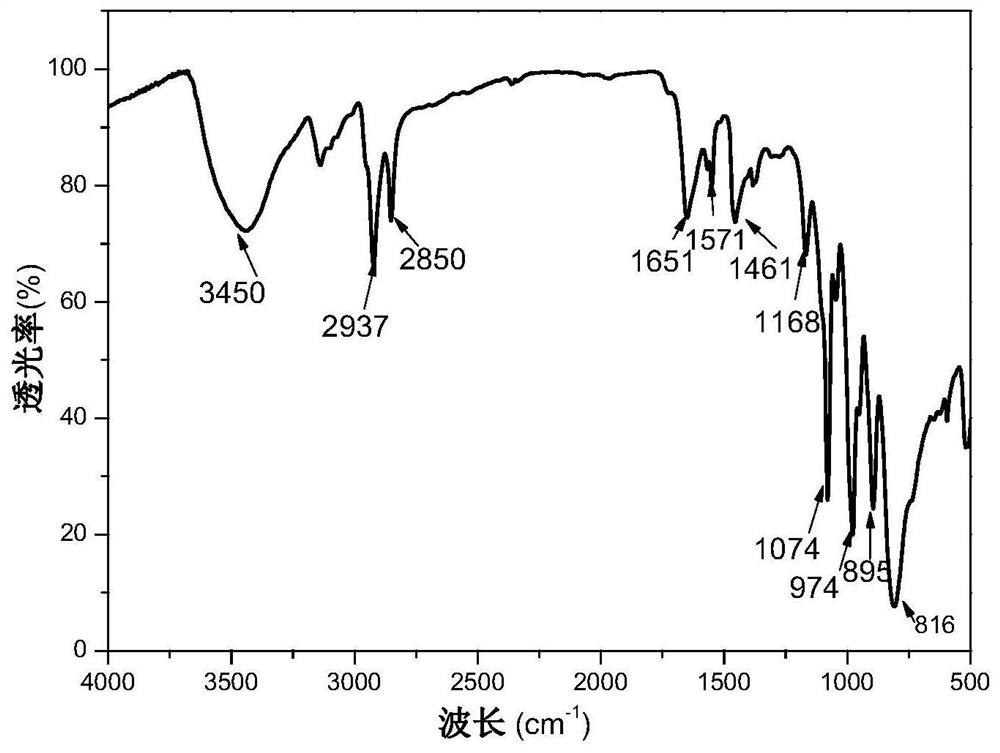

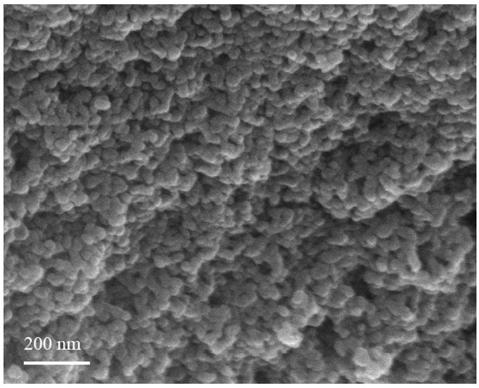

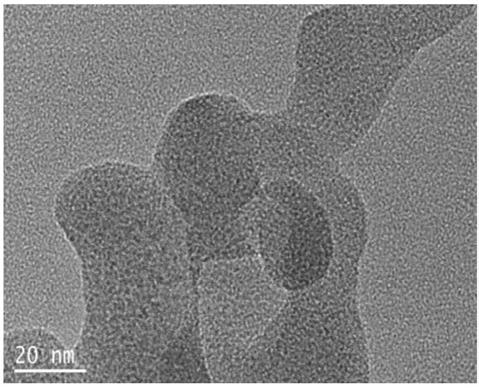

Mesoporous ion liquid heteropolyacid salt catalyst for benzene hydroxylation reaction, preparation method and applications thereof

InactiveCN107188849AEasy to manufactureHigh catalytic activityOrganic chemistryOrganic compound preparationCompound (substance)Hydrothermal synthesis

The present invention relates to the technical field of chemical catalysis, particularly to a mesoporous ion liquid heteropolyacid salt catalyst for a benzene hydroxylation reaction, a preparation method and applications thereof. The mesoporous ion liquid heteropolyacid salt catalyst is prepared by using a hydrothermal synthesis method, wherein the preparation method comprises: adding H5PMo10V2O40 heteropolyacid to a xylene-coupled imidazole ion liquid aqueous solution, carrying out a reaction, filtering, washing, and drying. According to the present invention, the prepared mesoporous ion liquid heteropolyacid salt catalyst is used in the reaction for phenol preparation through benzene oxidation; the catalysis performance of the mesoporous ion liquid heteropolyacid salt catalyst is improved through the mesoporous structure hydrophobic microenvironment so as to effectively improve the selectivity of phenol; the mesoporous ion liquid heteropolyacid salt catalyst has characteristics of simple preparation, low cost, convenient recovery, and stable reuse performance; and the preparation method has characteristics of rapid reation, mild condition and less environmental pollution, and is suitable for industrial production.

Owner:SHANDONG UNIV OF TECH

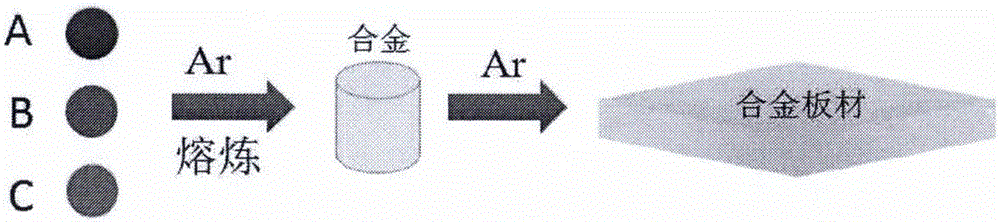

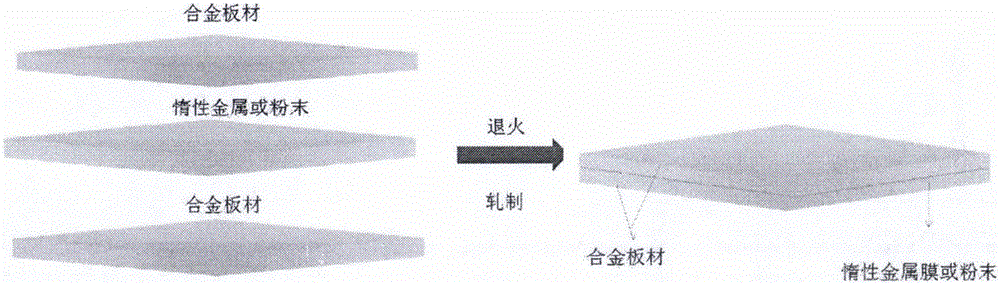

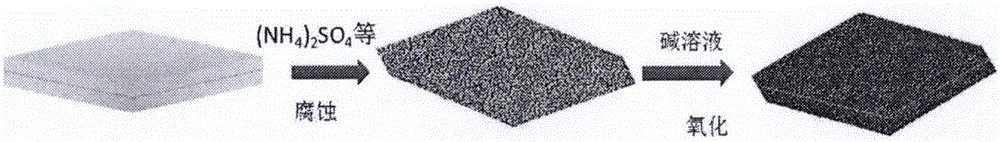

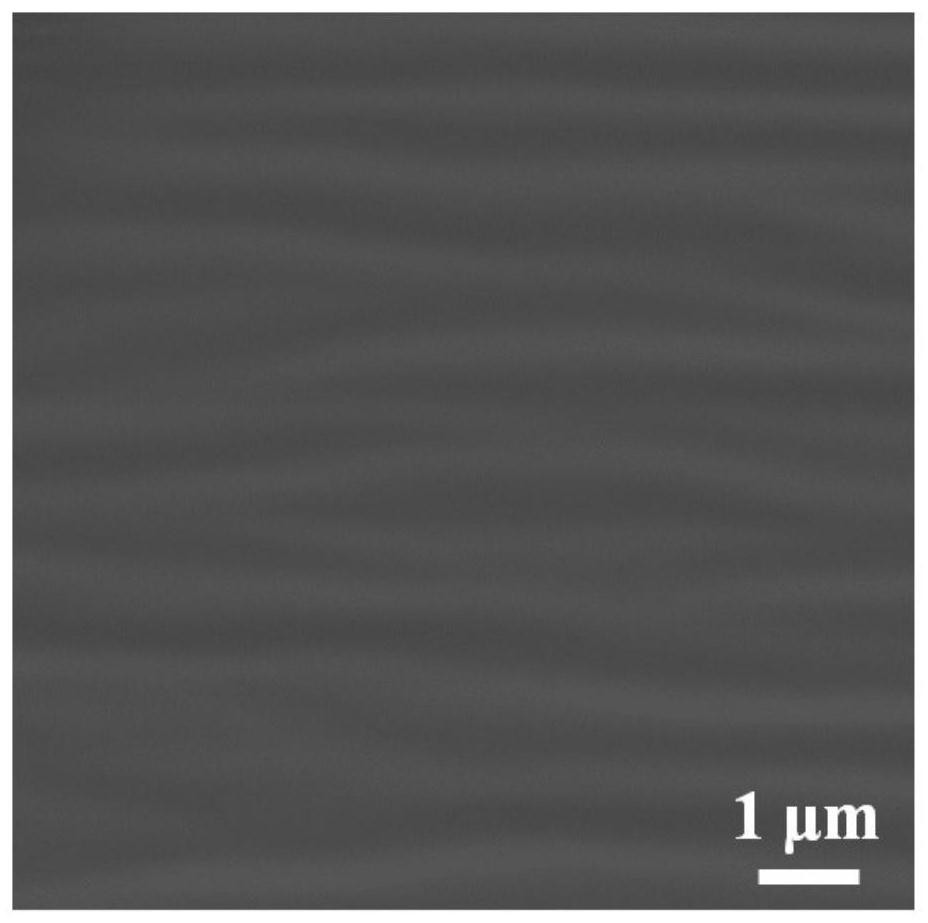

Flexible manometer porous metal foil electrode and preparation method thereof

ActiveCN106025247AImprove conductivityGood flexibilityCell electrodesNanotechnologyMetal alloyAlloy composite

The invention relates to a flexible manometer porous metal foil electrode. The flexible manometer porous metal foil electrode comprises a flexible conductive metal layer in the middle and metal alloy layers on the two sides, and the metal alloy layers on the two sides are of a manometer porous structure. The invention further relates to a preparation method of the electrode. The preparation method includes the steps that 1, metal alloy plates with uniform structural constituents are prepared; 2, the two layers of metal alloy plates and the flexible conductive metal layer in the middle are prepared into a three-layer alloy composite plate; 3, the alloy composite plate is subjected to annealing treatment; 4, the annealed alloy composite plate is subjected to hot rolling or cold rolling; 5, the step 3 and the step 4 are repeatedly carried out till the alloy composite plate reaches a preset thickness; 6, the obtained alloy composite plate is subjected to surface grinding; 7, finish rolling is carried out till the needed thickness is reached; 8, the obtained alloy composite plate is subjected to chemical and electrochemical corrosion treatment, and the manometer porous structure is formed on the surface metal alloy layers; 9, an obtained electrode is subjected to polarization or low-temperature annealing treatment to achieve partial self-oxidation of the electrode.

Owner:宁波杰士兄弟工具有限公司

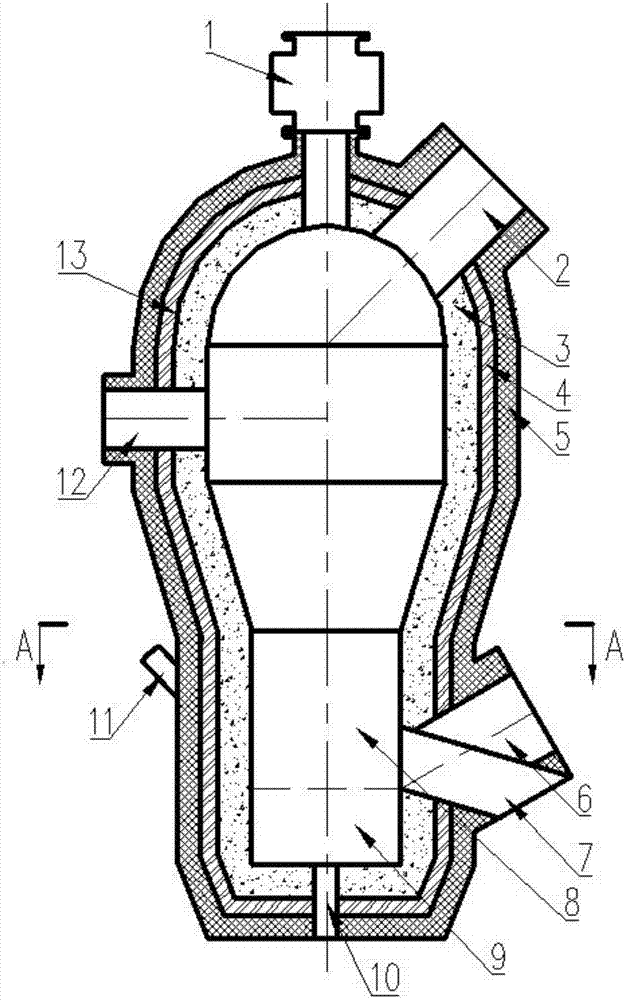

Water treatment system based on simultaneous production of ozone and hydrogen peroxide

ActiveCN104310534BLow application costYield maximizationWater/sewage treatment by electrochemical methodsWater/sewage treatment apparatusWater treatment systemSewage treatment

Owner:CHONGQING UNIV

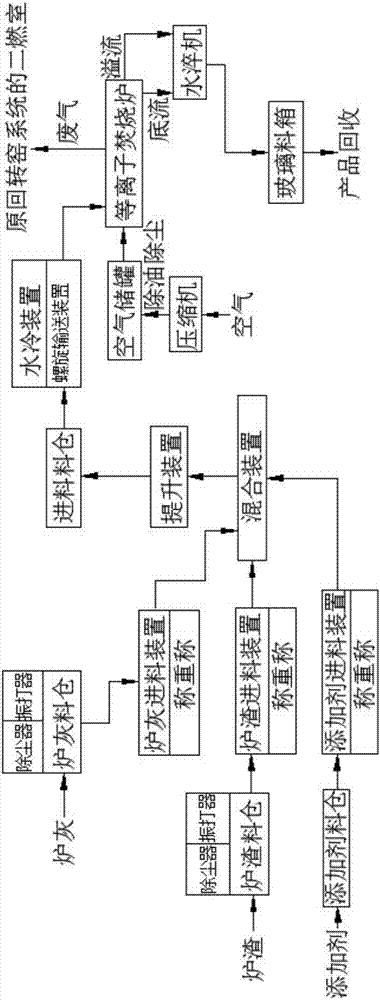

Plasma incinerating and melting system for disposing furnace ash and furnace slag and method for disposing furnace ash and furnace slag by use of plasma incinerating and melting system

PendingCN107504500ASave resourcesPromote environmental protectionIncinerator apparatusAutomatic controlSlag

The invention relates to a plasma incinerating and melting system for disposing furnace ash and furnace slag. The plasma incinerating and melting system comprises a dust catcher, a furnace slag stock bin, a furnace ash stock bin, an additive stock bin, a furnace slag feeding device, a furnace ash feeding device, an additive feeding device, a mixing device, a lifting device, a feeding stock bin, a spiral conveyor, a plasma incineration furnace, a water quenching machine, a glass body material box, a compressor and an air storage tank. The plasma incinerating and melting system can perform harmless and recycling treatment on the furnace ash and the furnace slag of a hazardous waste incinerator, and the furnace ash and the furnace slag, which are hazardous waste products, at the tail part of a hazardous waste treatment rotary kiln form nontoxic and harmless glass bodies which can serve as construction and building materials to be recycled, so that resources are saved, and environmental protection is facilitated. Therefore, the plasma incinerating and melting system can be widely applied to harmless and recycling treatment of furnace slag and fly ash at the tail part of the rotary kiln, and can realize whole-course automatic control.

Owner:AEROSPACE ENVIRONMENTAL ENG

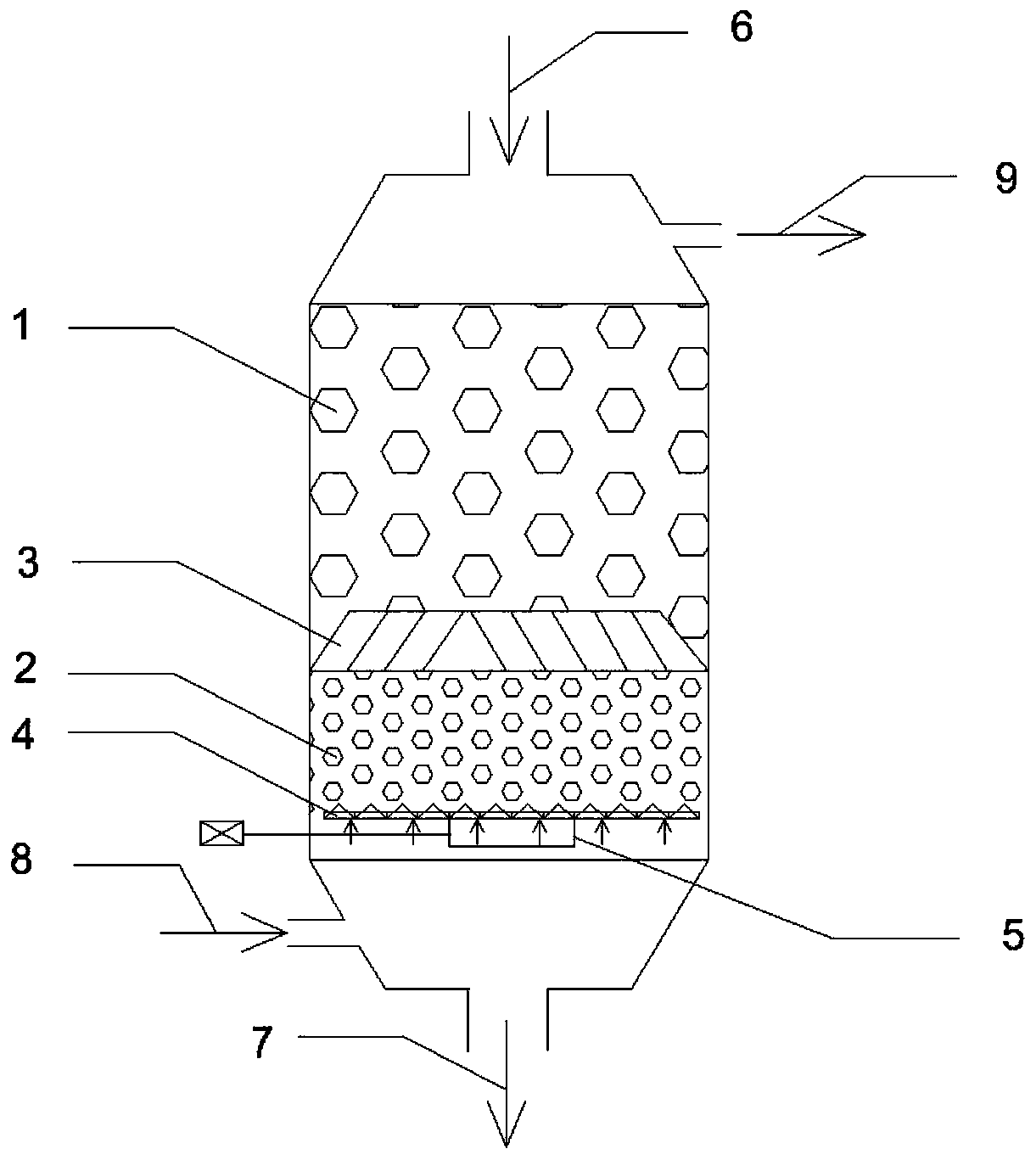

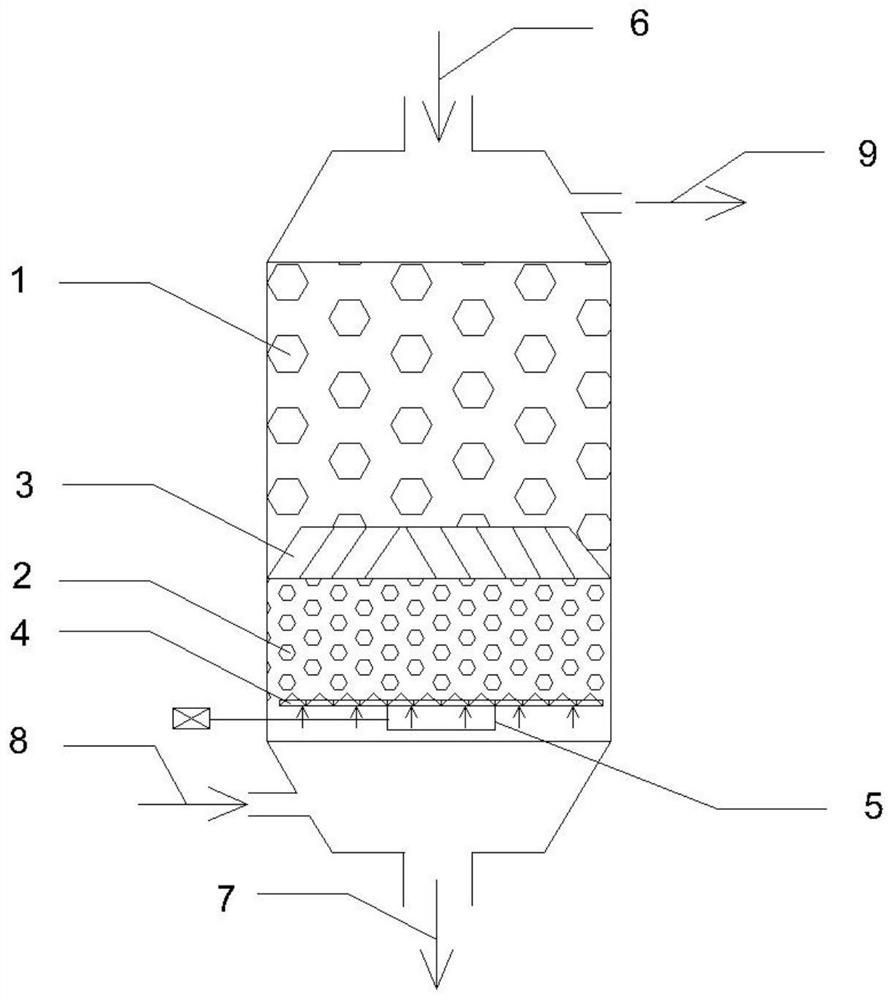

Method and device for desulfurization of high-temperature flue gas through forced grinding and on-line decomposition CaCO3

ActiveCN110639355ASimple processLow costGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention discloses a method and a device for desulfurization of high-temperature flue gas through forced grinding and on-line decomposition CaCO3. According to the invention, CaCO3 is adopted asa desulfurizing agent and is decomposed into CaO on line through heat energy of high-temperature flue gas, and CaO reacts with SO2; and in the desulfurization process, a grinding disc is adopted for rotary grinding so as to break a CaSO3 product shell layer wrapping the surfaces of CaO particles, so obstruction in the further reaction of CaO and SO2 is eliminated. A desulfurization reaction is carried out in an integrated reactor which comprises a CaCO3 decomposition zone, a desulfurization section, a grate bridge and the grinding disc; high-temperature flue gas which is not desulfurized enters the desulfurization section for the desulfurization reaction; and the desulfurized high-temperature flue gas enters the CaCO3 decomposition zone to continue decomposition of CaCO3 and then is discharged through a flue gas outlet to enter a subsequent process link. According to the invention, online decomposition of CaCO3 is carried out by utilizing the high-temperature flue gas, and surface updating of CaO is realized by utilizing forced grinding, so the desulfurizing agent, namely CaCO3 is fully utilized, desulfurization efficiency is greatly improved, the purity of the desulfurization product gypsum is guaranteed, and desulfurization cost is reduced; and the device is simple in structure and convenient to implement.

Owner:XIANGTAN UNIV

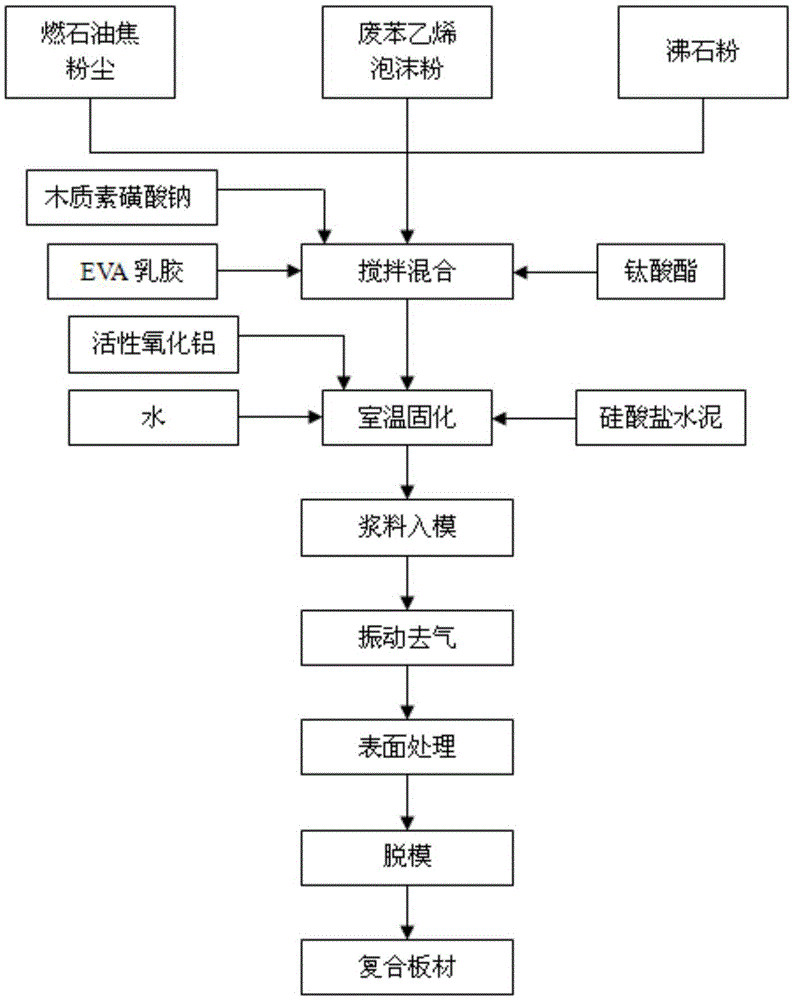

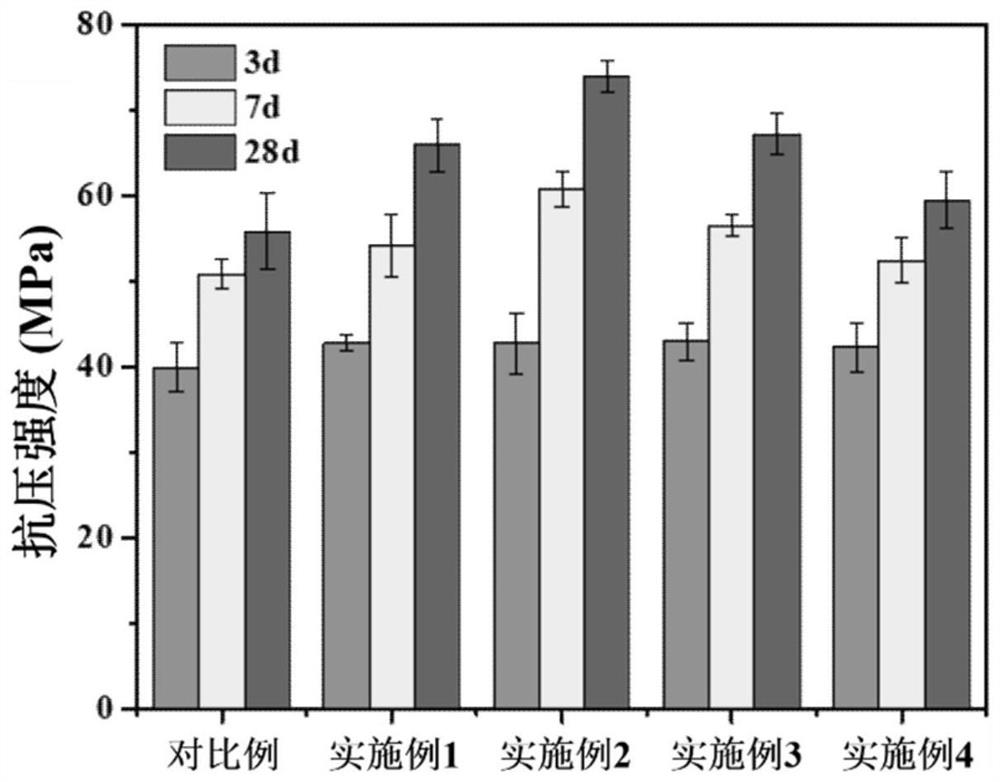

Resourceful treatment method for petroleum coke burning dust

The invention provides a resourceful treatment method for petroleum coke burning dust. The petroleum coke burning dust, waste styrene foam powder and zeolite are solidified into a composite board at normal temperature through surface modification, cement solidification and powerful adhesion, the petroleum coke burning dust with the particle size range of 100 micrometers or below, the waste styrene foam powder with the particle size range of 5-10 mm and the zeolite powder with the particle size range of 1-5 mm are subjected to auxiliary adding, stirring and mixing, room temperature solidifying, molding by casting, bubble removing, surface treatment, demolding and drying, and the composite board is obtained. No pollution is caused in the manufacturing process, the technology is simple, cost is low, the prepared board is high in practical value, and resourceful utilization of the petroleum coke burning dust is achieved.

Owner:BEIJING JINGCHUANGDA SCI & TECH

Formaldehyde-free flame-retardant magnesium oxychloride cement-based wood adhesive and preparation method thereof

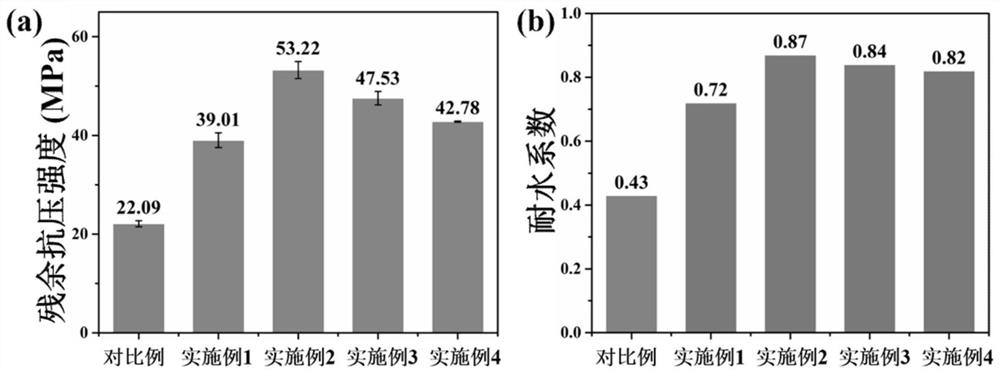

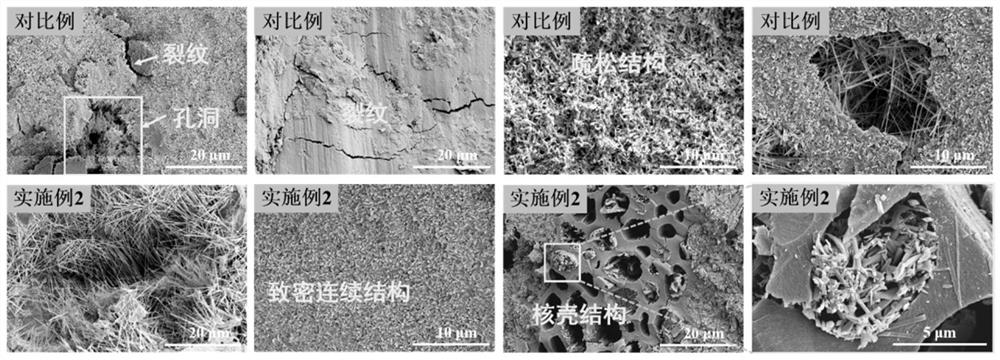

PendingCN114525079ASolve pollutionAddress fire hazardsNon-macromolecular adhesive additivesSolid waste managementHydration reactionCompressive resistance

The invention relates to the technical field of inorganic adhesives, in particular to a formaldehyde-free flame-retardant magnesium oxychloride cement-based wood adhesive and a preparation method thereof. The adhesive is prepared from the following components in parts by weight: 100 to 150 parts of light calcined magnesia, 60 to 100 parts of magnesium chloride hexahydrate and 5 to 40 parts of charcoal. The adhesive provided by the invention has the characteristics of good water resistance, high compressive strength, flame retardance, no formaldehyde release, high bonding strength and low cost, can relieve a wood filtration effect, realizes structural regulation and control of magnesium oxychloride cement at a wood bonding interface, eliminates a weak interface layer, and can meet process requirements and practical performance of the adhesive.

Owner:BEIJING FORESTRY UNIVERSITY

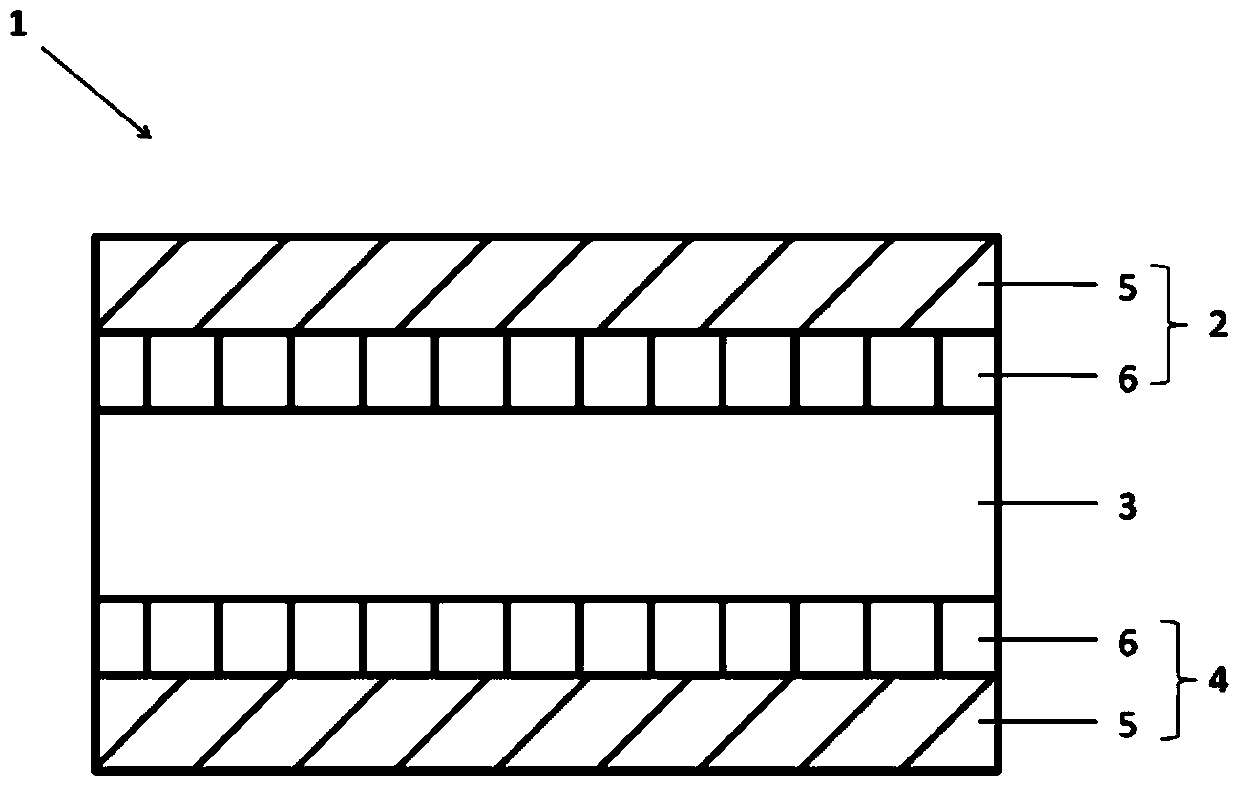

Tarpaulin with high strength as well as preparation method and application thereof

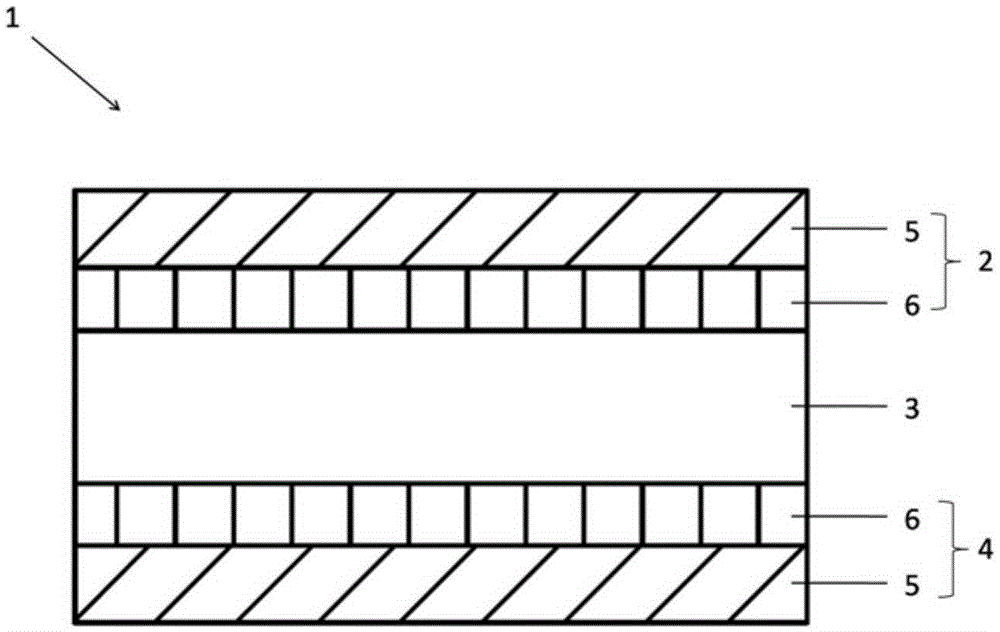

ActiveCN106881913AImprove mechanical propertiesGood flame retardancyLaminationLamination apparatusSurface layerHigh intensity

The invention provides a piece of tarpaulin with high strength as well as a preparation method and an application thereof. The tarpaulin with high strength comprises a surface layer, a core layer and a bottom layer; the surface layer and the bottom layer are prepared from non-woven fabrics with resin coated on one side, and the core layer is prepared by a fiber enhanced thermoplastic resin prepreg. The preparation method of the tarpaulin with high strength comprises the following steps: two or more fiber enhanced thermoplastic resin prepreg tapes are laminated and laid on the other side of the non-woven fabrics with resin coated on one side where the resin material is not coated layer by layer in a 0 degree and 90 degrees alternated mode, the other non-woven fabric with resin coated on one side is laid on an uncombined surface of the fiber enhanced thermoplastic resin prepreg tape which is laid at last, so that the other side of the non-woven fabric with resin coated on one side where the resin material is not coated and the uncombined surface are attached, and after post processing, the tarpaulin with high strength is obtained. The tarpaulin with high strength not only has good strength, and has flame retardation, aging resistance, other performances, and long service life; in addition, the preparation method has simple process and high production efficiency.

Owner:上海昶勤实业有限公司

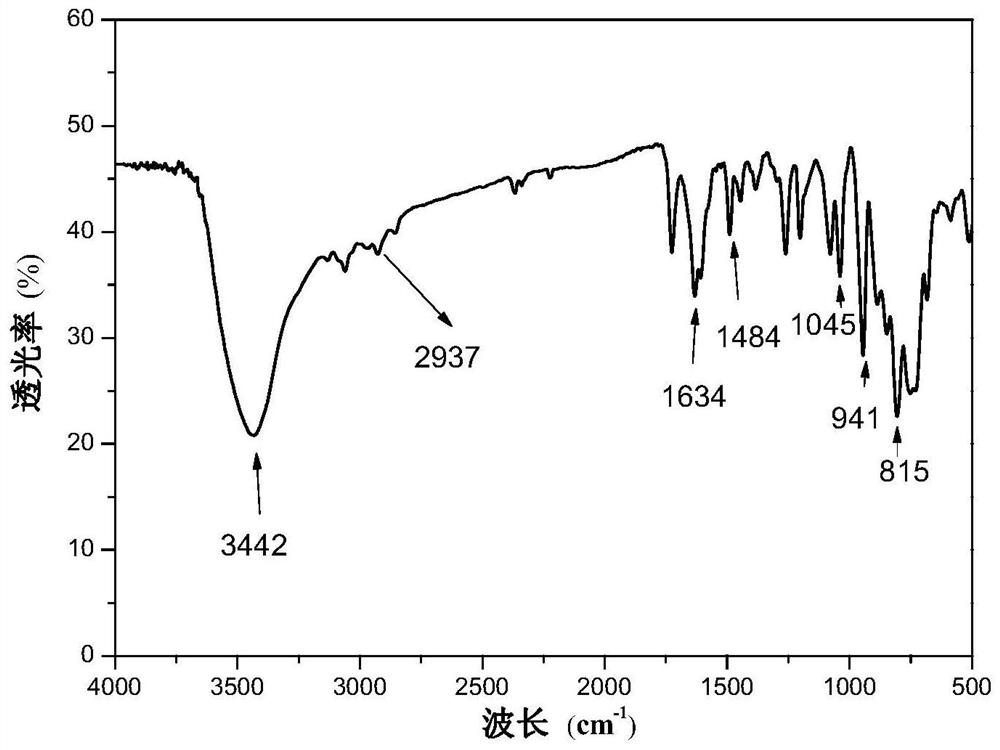

Polyionic liquid-based heteropolyacid catalyst for olefin epoxidation reaction, preparation method and application thereof

ActiveCN108465487AIncrease profitMild reaction conditionsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationIon exchange

The invention relates to a polyionic liquid-based heteropolyacid catalyst for olefin epoxidation reaction, a preparation method thereof and application thereof, and belongs to the field of chemical catalysis. The preparation method of the catalyst provided by the invention comprises the steps of: adding H3PW12O40 heteropolyacid to a piperidine-functionalized polyionic liquid solution to obtain a white solid particle by ion exchange reaction, and the polyionic liquid-based heteropolyacid catalyst is obtained by filtration, washing and drying of the white solid particle. The obtained catalyst isused in the olefin epoxidation reaction, reaction results are detected by GC, the conversion rate is up to 100%, and the selectivity is up to 97%. The catalyst has the advantages that piperidine-functionalized ionic liquid cations are combined with heteropolyanions, charge transfer in catalyst molecules can be effectively increased, the reaction is accelerated, the yield of an epoxy compound is improved, the catalyst is insoluble in the system in the reaction, and can be reused by simple filtration, and the catalyst has high catalytic activity and long life.

Owner:SOUTHEAST UNIV CHENGXIAN COLLEGE

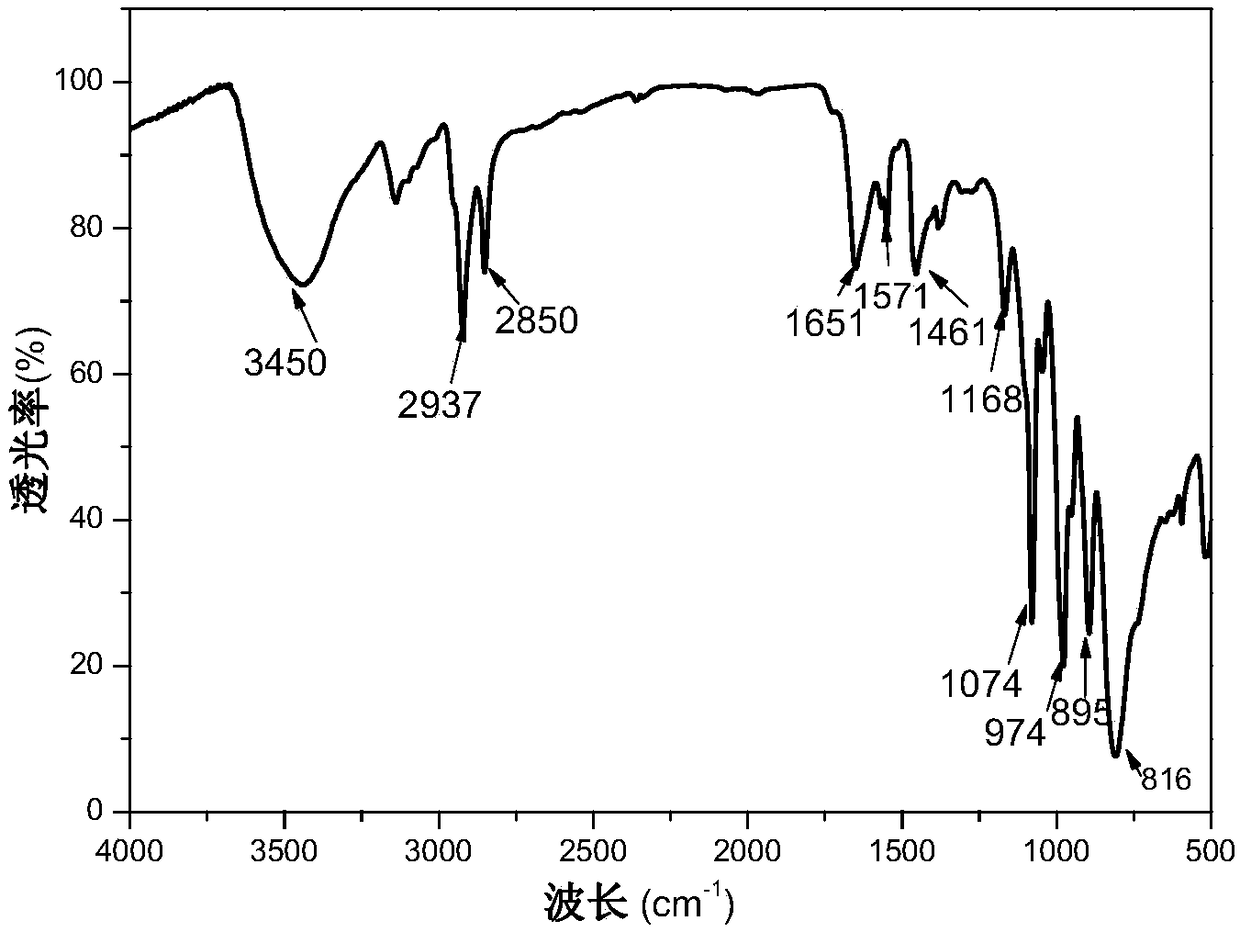

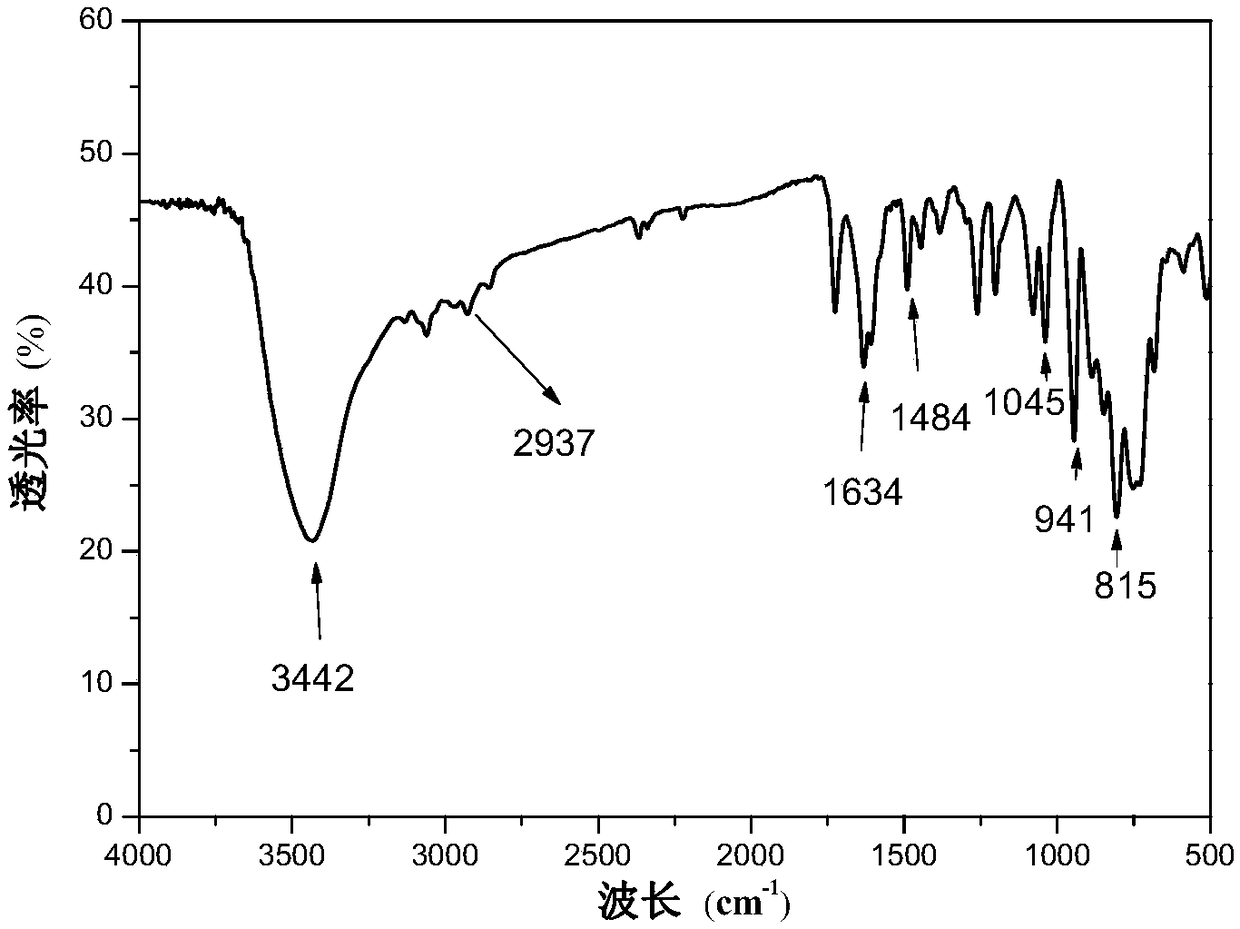

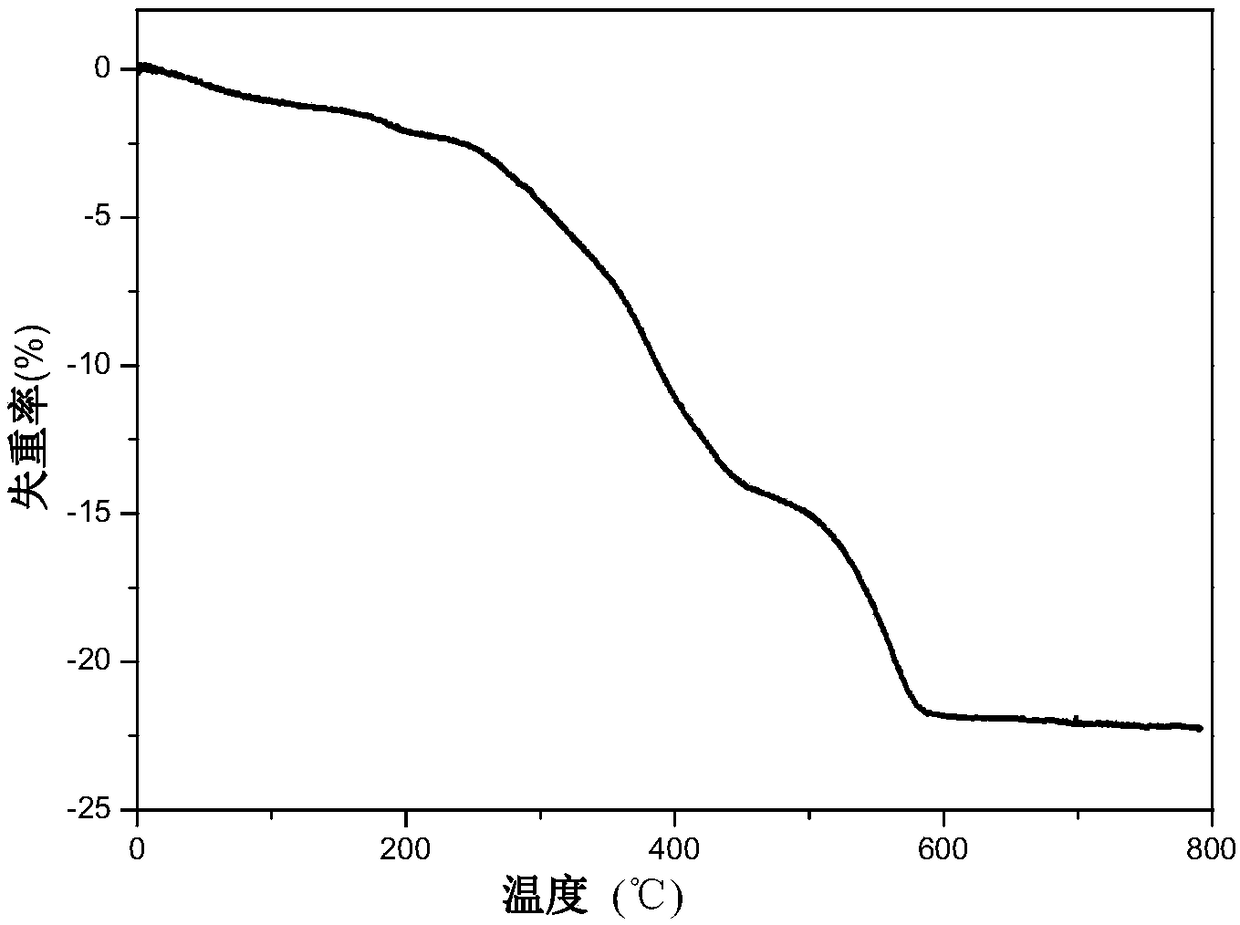

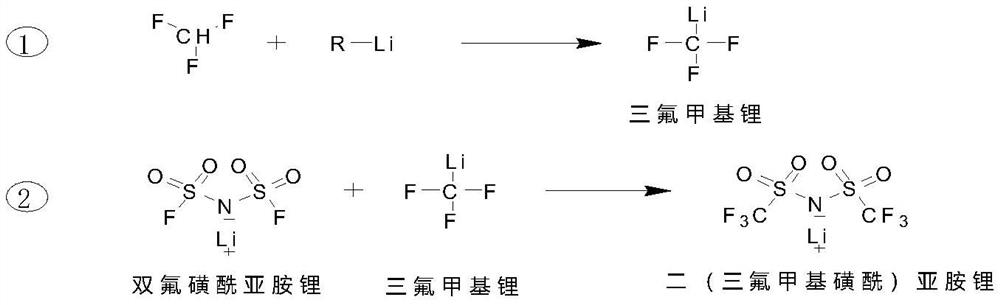

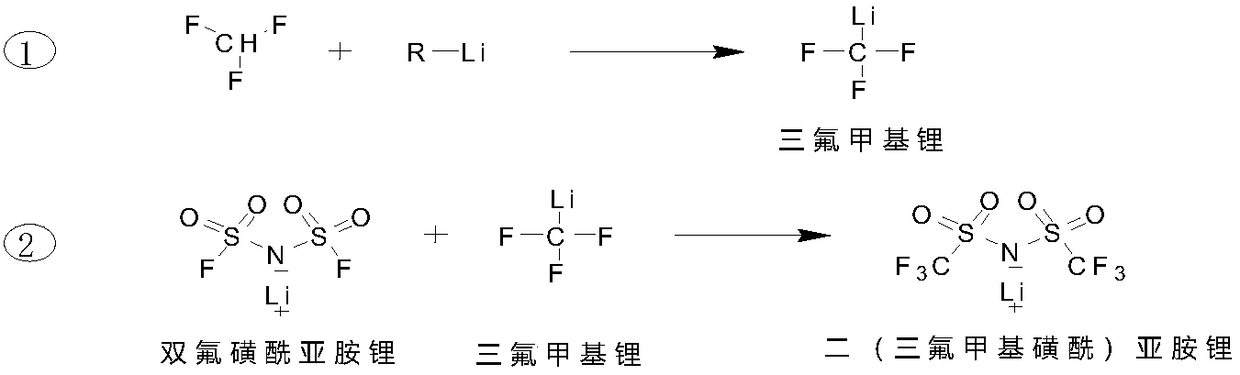

A kind of preparation method of bis(trifluoromethylsulfonyl)imide lithium salt

ActiveCN109369474BReduce the difficulty of separationSimple process routeLithium organic compoundsSulfonic acid amide preparationImidePhysical chemistry

The invention provides a preparation method of bis(trifluoromethylsulfonyl)imide lithium salt, which is characterized in that trifluoromethane gas is passed into the non-polar lithium alkyl lithium salt under anhydrous, nitrogen protection and low temperature conditions. React in solvent solution to prepare trifluoromethyllithium. After the reaction is completed, slowly add bisfluorosulfonyl imide lithium solution to the trifluoromethyllithium solution under low temperature conditions. During the dropping process, white solids will be precipitated. Finally, the reaction solution was filtered, and the filtrate was evaporated to dryness under reduced pressure to obtain a white solid wet salt, which was dried in vacuo to obtain bis(trifluoromethylsulfonyl)imide lithium salt. The present invention has the advantages of realizing the one-pot synthesis of lithium bis(trifluoromethylsulfonyl)imide, which greatly simplifies the process route compared with the traditional method, reduces the difficulty of separating products and by-products in the reaction process, and improves product purity. Thereby further reducing production costs, improving product performance and cost competitiveness, and providing feasible technical support for large-scale industrial production.

Owner:ZHANGJIAGANG HUASHENG CHEM CO LTD

Preparation method of lithium bis(trifluoromethanesulphonyl)imide salt

ActiveCN109369474ASimple process routeReduce the difficulty of separationLithium organic compoundsSulfonic acid amide preparationSolventChemistry

The invention provides a preparation method of lithium bis(trifluoromethanesulphonyl)imide salt. The preparation method is characterized by comprising steps as follows: trifluoromethane gas is introduced into a non-polar solvent solution of lithium alkylide at low temperature under anhydrous and nitrogen protective conditions and subjected to a reaction, trifluoromethyl lithium is prepared, afterthe reaction, a lithium bis(fluorosulfonyl)imide solution is slowly dropwise added to the trifluoromethyl lithium solution at the low temperature, white solids can be separated out in a dropwise adding process, a reaction solution is filtered after dropwise addition is finished, a filtrate is evaporated under reduced pressure to be dry, white solid wet salt is obtained and subjected to vacuum drying, and lithium bis(trifluoromethanesulphonyl)imide salt is obtained. The preparation method has the advantages as follows: bis(trifluoromethanesulphonyl)imide is synthesized with a one-pot method, compared with a traditional method, a process route is greatly simplified, separating difficulty of a product and a byproduct in a reaction process is reduced, product purity is improved, so that production cost is further reduced, product performance and cost competitiveness are improved, and feasible technical support is provided for large-scale industrial production.

Owner:ZHANGJIAGANG HUASHENG CHEM CO LTD

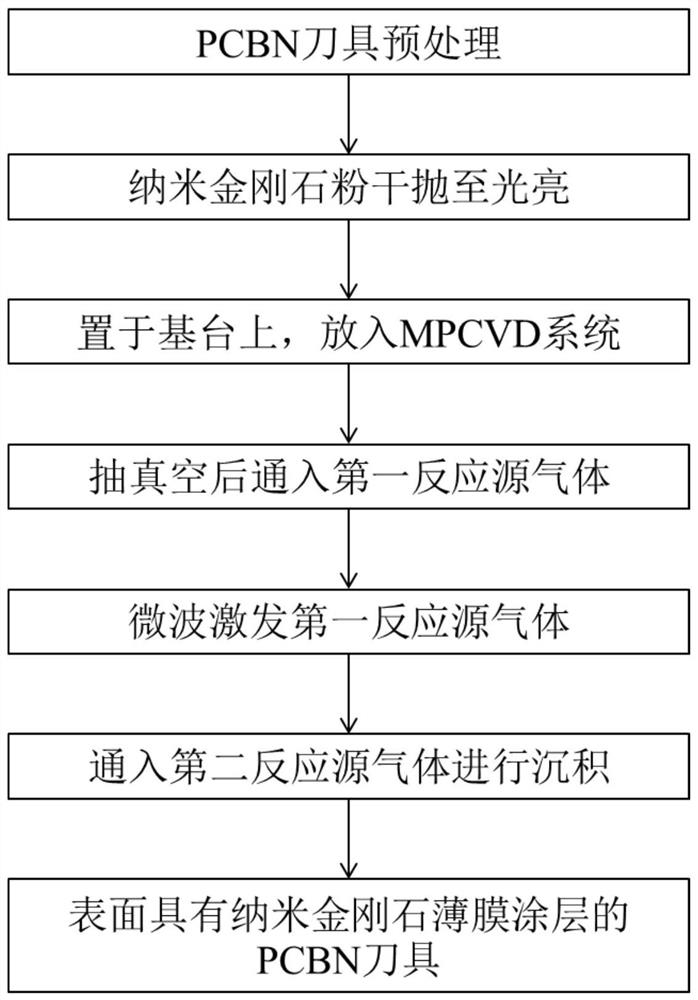

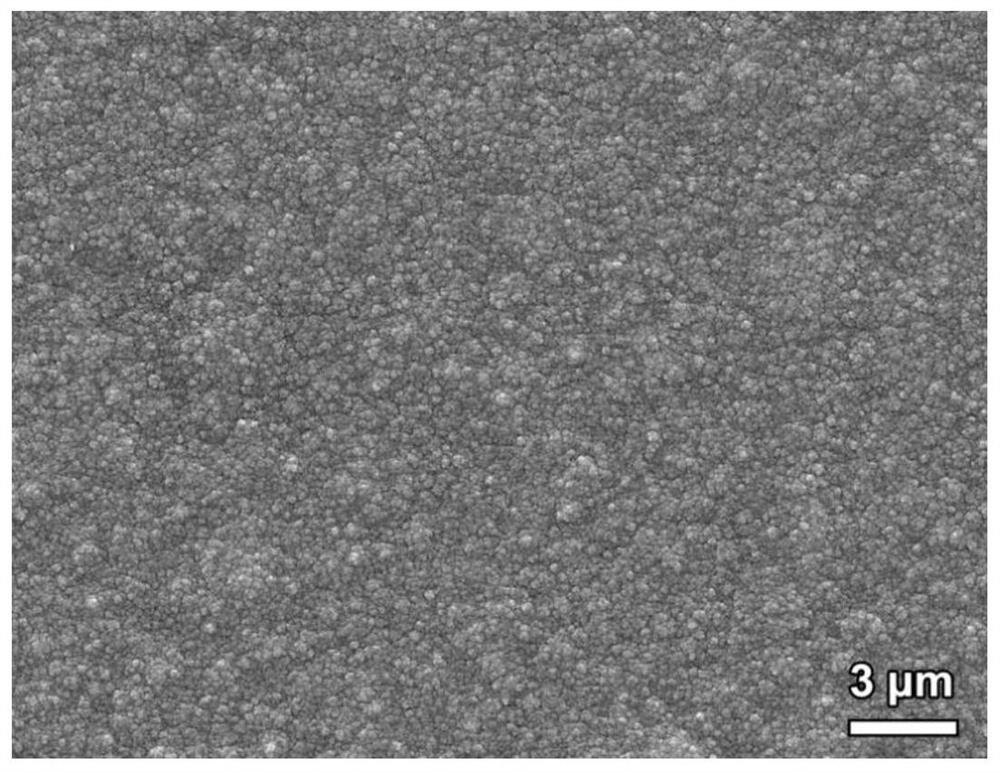

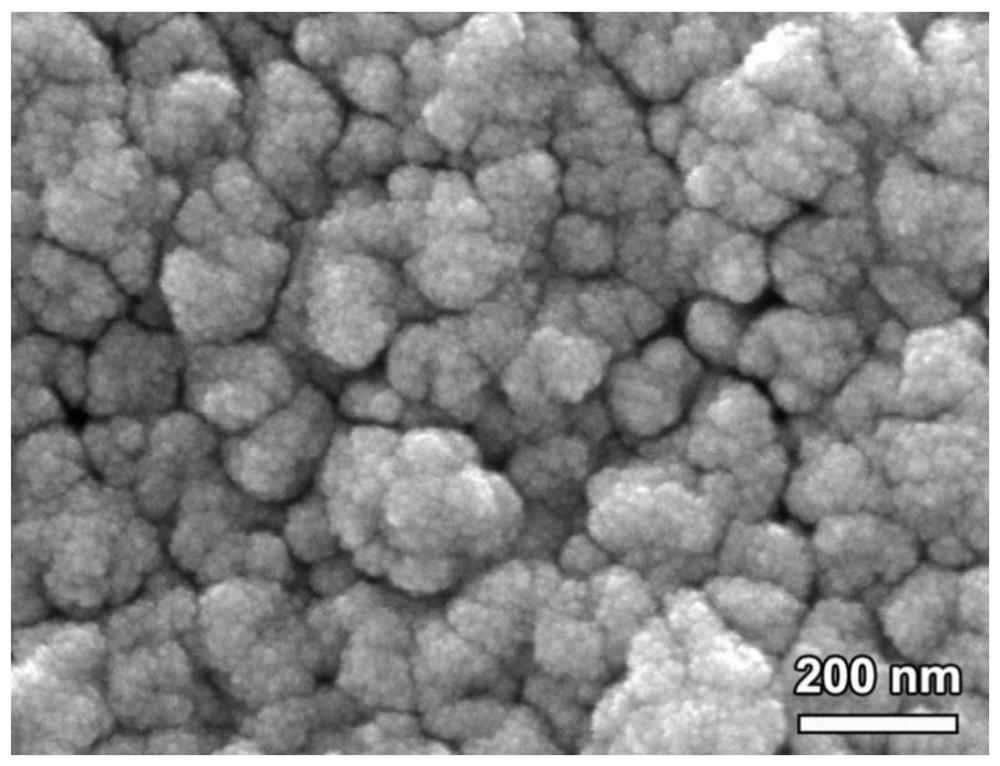

PCBN cutter with nano diamond film coating on surface and preparation method of PCBN cutter

PendingCN113403602AImprove adhesion strengthImprove bindingChemical vapor deposition coatingFilm coatingFilm-coated tablet

The invention provides a PCBN cutter with a nano diamond film coating on the surface and a preparation method of the PCBN cutter. The preparation method comprises the following steps that the pretreated PCBN cutter is subjected to dry polishing in nano-diamond powder to be bright and then placed on a base station, the base station is placed in a microwave plasma chemical vapor deposition system to be vacuumized, vacuumizing is conducted, and then a first reaction source gas is introduced; and the microwave plasma chemical vapor deposition system is started, the first reaction source gas is excited by microwaves to generate plasma balls, then a second reaction source gas is introduced to start deposition, and the PCBN cutter with the nano-diamond film coating on the surface is obtained after deposition is completed. According to the preparation method, the microwave plasma chemical vapor deposition process is optimized, the nano-scale diamond coating is uniformly deposited on the surface of the cutter by regulating and controlling preparation conditions, the film quality and stability of the diamond coating are effectively improved, the service life of the cutter is prolonged, and the preparation method has good industrial application prospects.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

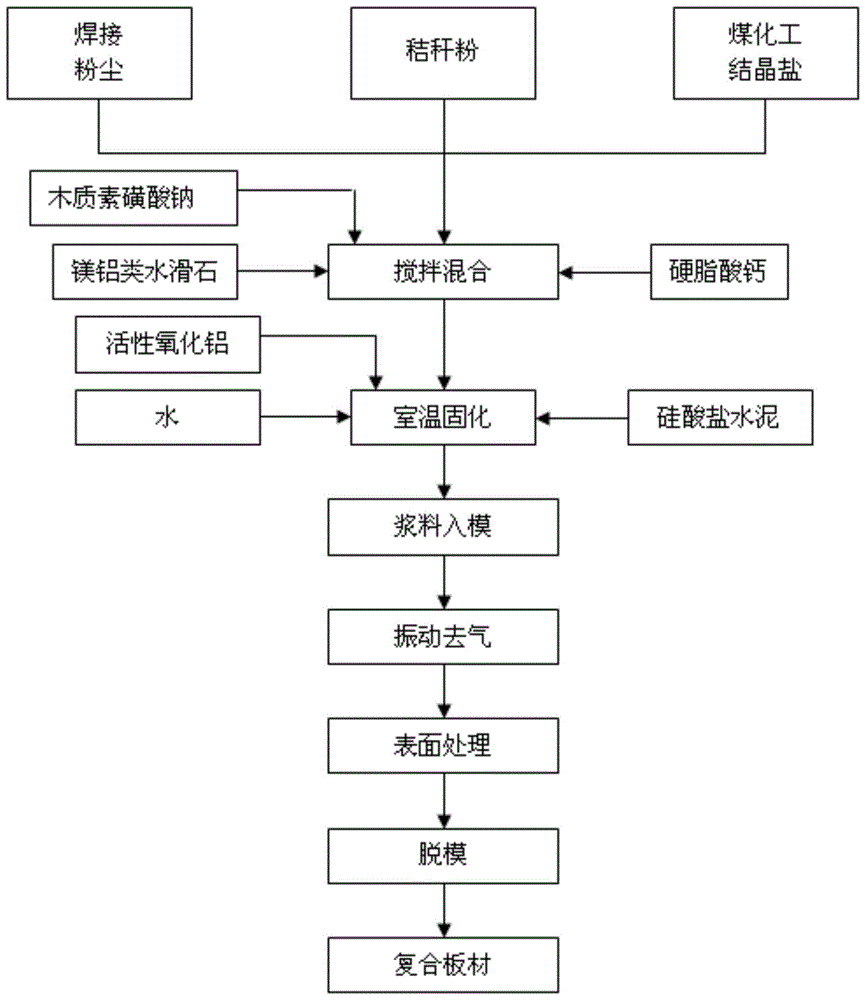

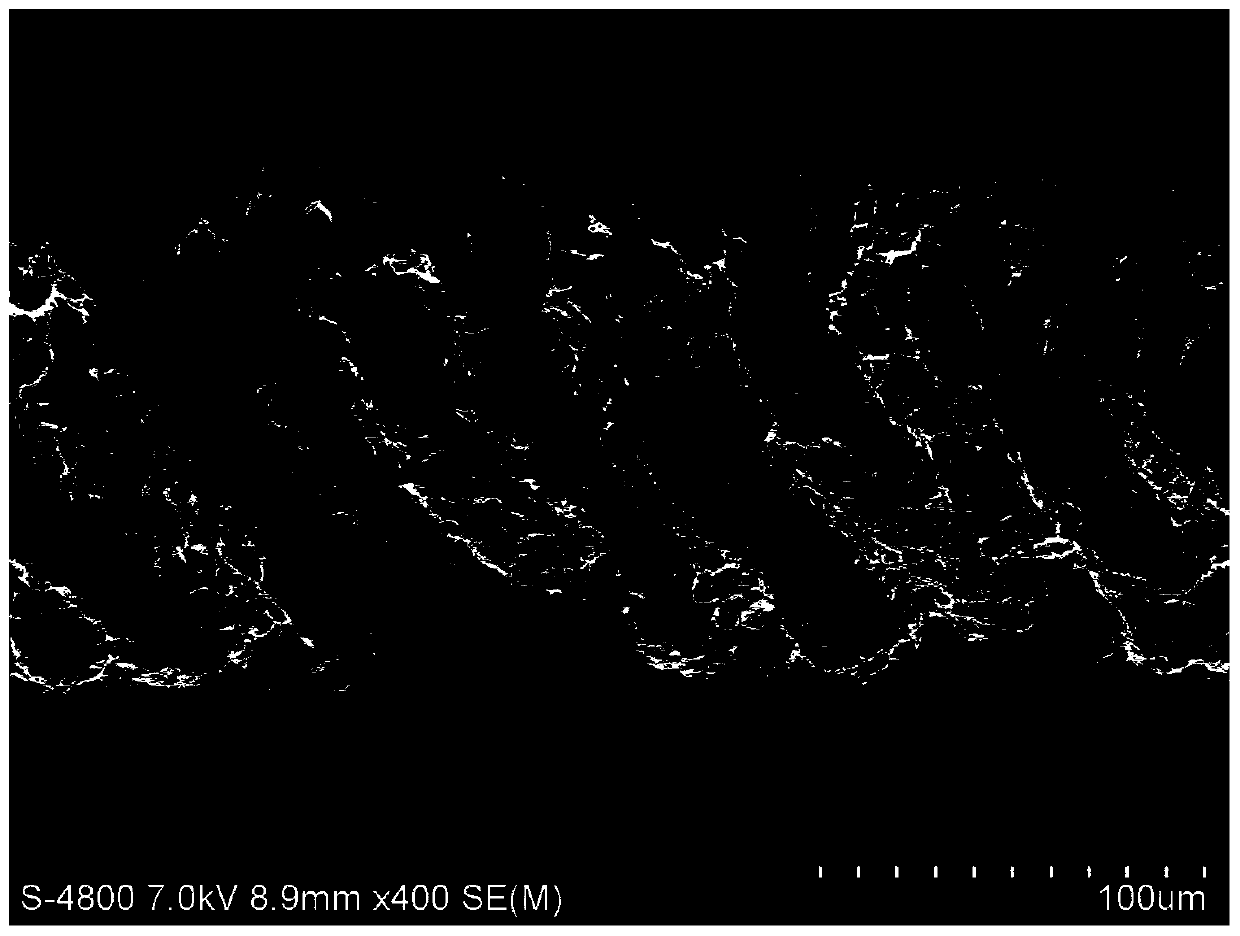

Method for resourceful treatment of industrial solid waste

ActiveCN105776984ALow costImprove the interface binding forceSolid waste managementComposite platePollution

The invention provides a method for resourceful treatment of industrial solid waste.Welding dust, straw powder and coal chemical crystalline salt are solidified into a composite plate at normal temperature through surface modification, inflaming retarding and cement solidification, and auxiliary adding, stir-mixing, room temperature curing, casting molding, bubble removal, surface treatment, demolding and drying are conducted on welding dust with particle size smaller than 100 microns, straw powder with particle size being 5-10 micrometers, and coal chemical crystalline salt with particles size being 1-5 micrometers so as to obtain the composite plate.The manufacturing process is free of pollution, the technology is simple, cost is low, the manufactured plate is high in practical value, and resourceful utilization of industrial solid waste is achieved.

Owner:辽宁绿源再生能源开发有限公司

A method for separating L-glutamic acid and L-pyroglutamic acid from L-glutamic acid refining mother liquor

ActiveCN104177269BAchieve separationSpeed up the coking reaction rateOrganic compound preparationAmino-carboxyl compound preparationL-Pyroglutamic AcidGlutamic acid

The invention relates to a method for separating L-glutamic acid and L-pyroglutamic acid from a glutamic acid refinement mother solution. The method comprises the following steps: 1) carrying out vacuum concentration on the glutamic acid refinement mother solution, cooling to crystallize, and centrifugating, wherein the solid is the L-glutamic acid crude product, and the liquid is for later use; 2) washing the L-glutamic acid crude product with water to obtain pure L-glutamic acid; and 3) heating the liquid obtained in the step 1), carrying out pressurized pyrogenic reaction, cooling, concentrating, cooling to crystallize, centrifugating, collecting the precipitate, adding water to a saturated state, recrystallizing, cooling, and carrying out centrifugal separation to obtain the L-pyroglutamic acid. The method is simple in technical process, and can well solve the problem of the separation technique for glutamic acid and pyroglutamic acid, thereby achieving the goals of enhancing the L-glutamic acid refinement yield and coproducing the L-pyroglutamic acid.

Owner:BENGBU BBCA MEDICINE SCI DEV

Manufacturing method of composite enhanced insulating section bar

The invention discloses a manufacturing method of a composite enhanced insulating section bar. According to the invention, with a modification technology and a room temperature solidification technology, waste circuit board resin powder, waste polyurethane powder and biomass powder are solidified into a section bar under room temperature. Specific steps of the method are that: after a sieving process, waste circuit board resin powder with a granularity range of 0.5 to 5mm, waste polyurethane powder with a granularity range of 1 to 20 mm, and biomass powder with a granularity range of 1 to 10mm are blended-modified, and cemented; the slurry is injected into a testing mold, and is shaped; the testing mold with injected slurry is placed on a vibrating machine to be vibrated for 1 to 5min, such that air bubbles are removed, and a hydro-thermal synthesizing reaction of the gel material is accelerated; the material is then processed through a surface treatment process that the surface of the slurry is flattened; the slurry is stood for 24 hours, and is demolded; the resulting material is dried, such that the composite enhanced section bar is obtained. According to the invention, no pollution is brought to the manufacturing processes. The technology is simple; the cost is low; the produced section bars have great application value; and low-carbon, environment protection and resource re-utilization are realized.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

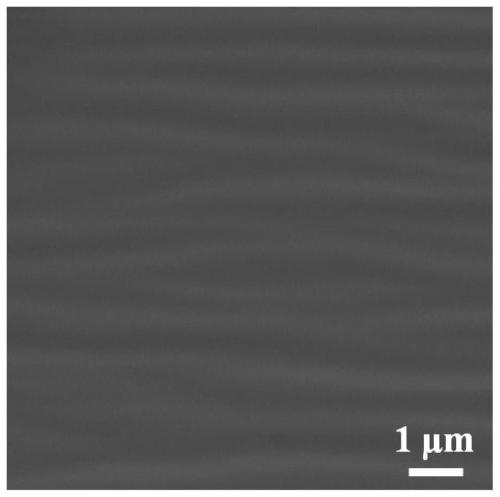

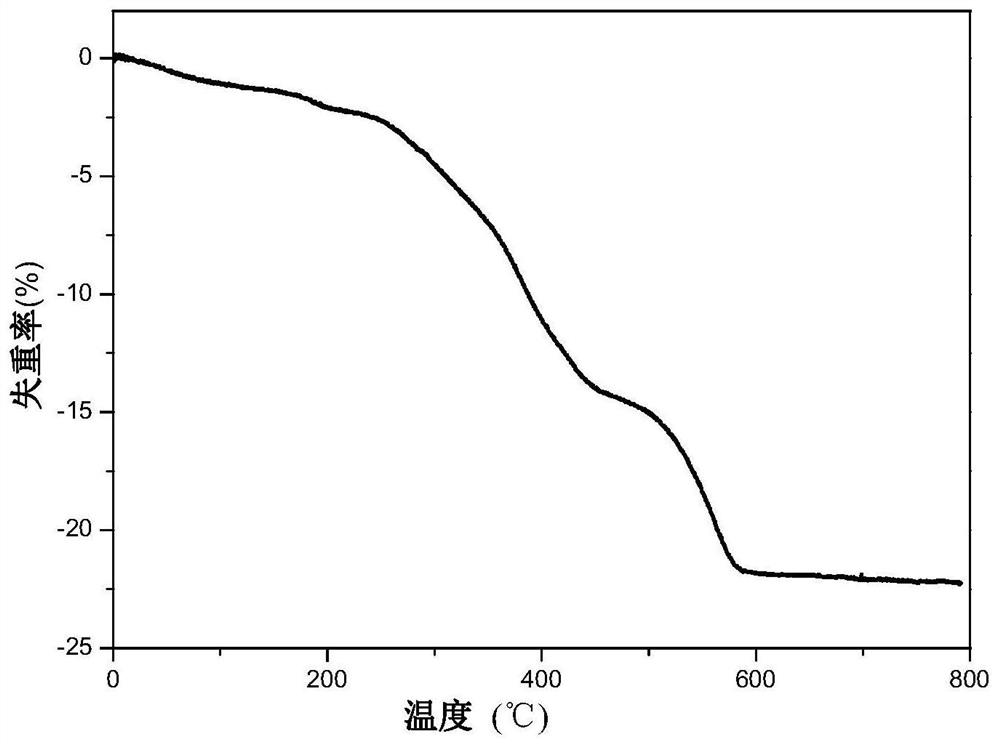

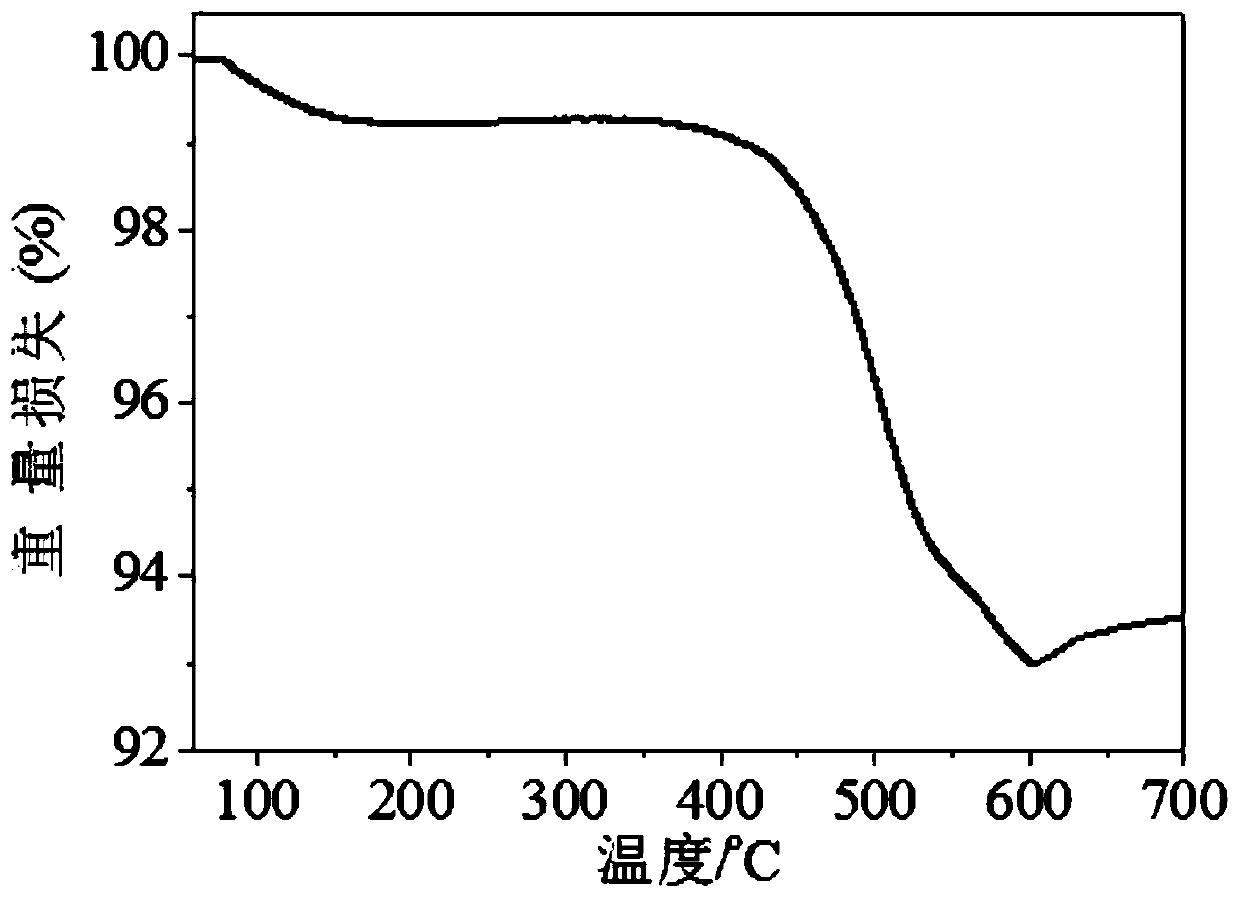

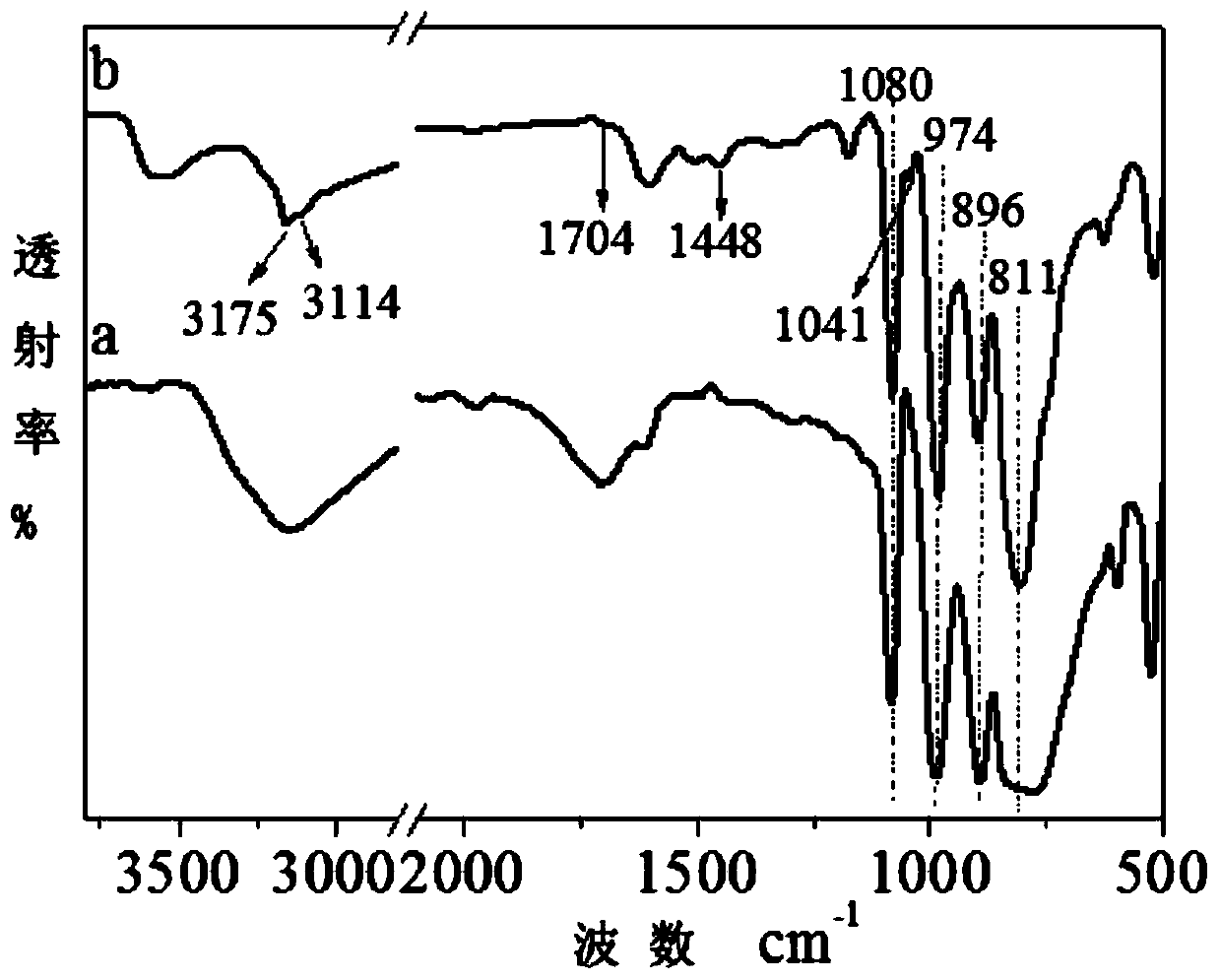

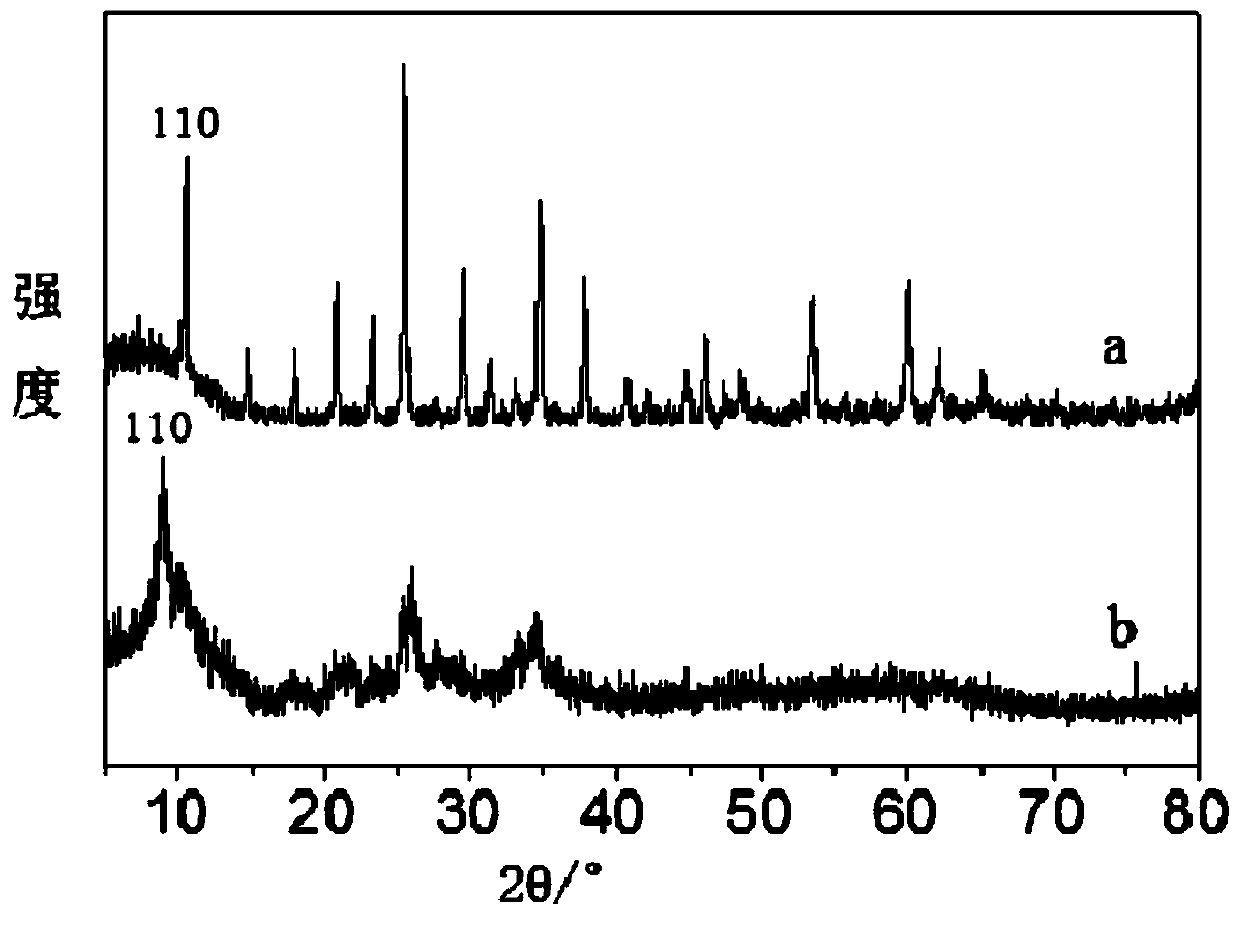

Polymer-based blended membrane and preparation method and application thereof

ActiveCN111298667AImprove thermal stabilityImprove solubilitySemi-permeable membranesGas treatmentPolymer scienceCITRATE ESTER

The invention discloses a polymer-based blended membrane. The polymer-based blended membrane comprises a polymer matrix and a blending agent, the polymer matrix comprises at least one of thermoplasticpolymers, and the blending agent comprises at least one of citric acid ester and citric acid derivative ester. The polymer-based blended membrane has high CO2 separation performances and high thermalstability. By adding the blending agent, the structure of the polymer membrane material is modified, the CO2 affinity of the polymer membrane is improved, and the CO2 separation performance of the polymer-based blended membrane material is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of high-strength tarpaulin and its production method and application

ActiveCN106881913BImprove mechanical propertiesGood weather resistanceLaminationLamination apparatusPolymer scienceNonwoven fabric

The invention provides a piece of tarpaulin with high strength as well as a preparation method and an application thereof. The tarpaulin with high strength comprises a surface layer, a core layer and a bottom layer; the surface layer and the bottom layer are prepared from non-woven fabrics with resin coated on one side, and the core layer is prepared by a fiber enhanced thermoplastic resin prepreg. The preparation method of the tarpaulin with high strength comprises the following steps: two or more fiber enhanced thermoplastic resin prepreg tapes are laminated and laid on the other side of the non-woven fabrics with resin coated on one side where the resin material is not coated layer by layer in a 0 degree and 90 degrees alternated mode, the other non-woven fabric with resin coated on one side is laid on an uncombined surface of the fiber enhanced thermoplastic resin prepreg tape which is laid at last, so that the other side of the non-woven fabric with resin coated on one side where the resin material is not coated and the uncombined surface are attached, and after post processing, the tarpaulin with high strength is obtained. The tarpaulin with high strength not only has good strength, and has flame retardation, aging resistance, other performances, and long service life; in addition, the preparation method has simple process and high production efficiency.

Owner:上海昶勤实业有限公司

A polymer-based blend film, its preparation method and application

ActiveCN111298667BImprove thermal stabilityImprove solubilitySemi-permeable membranesGas treatmentPolymer scienceCITRATE ESTER

The application discloses a polymer-based blend film, comprising a polymer matrix and a blending agent; the polymer matrix includes at least one of thermoplastic polymers; the blending agent includes citric acid ester, citric acid derivative at least one of esters. with high CO 2 Polymer-based blended membrane with separation performance and high thermal stability; by adding a blending agent, the structure of the polymer membrane material is modified to increase the CO of the polymer membrane 2 Affinity to improve the CO of polymer-based blend membrane materials 2 separation performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A force ground caco 3 On-line decomposition high temperature flue gas desulfurization method and device

ActiveCN110639355BSimple processLow costGas treatmentDispersed particle separationThermodynamicsFlue gas

The invention discloses a forced grinding CaCO 3 On-line decomposition high-temperature flue gas desulfurization method and device. Using CaCO 3 As a desulfurizer, the heat energy of high-temperature flue gas is used to convert CaCO 3 On-line decomposed into CaO and combined with SO 2 In the process of reaction and desulfurization, the grinding disc is used to rotate and grind to break the CaSO wrapped on the surface of CaO particles 3 Product shell, elimination of CaO and SO 2 hindrance to further reactions. The desulfurization reaction is carried out in an integrated reactor, including CaCO 3 Decomposition area, desulfurization section, furnace bridge, grinding disc, high-temperature flue gas without desulfurization enters the desulfurization section for desulfurization reaction, and high-temperature flue gas after desulfurization enters the CaCO 3 The decomposition zone continues to complete the CaCO 3 Decomposition, and then discharged through the flue gas outlet into the follow-up process. The present invention uses high-temperature flue gas to implement CaCO 3 The on-line decomposition of CaO by forced grinding is used to update the surface of CaO, so that the desulfurization agent is fully utilized, greatly improving the desulfurization efficiency, while ensuring the purity of the desulfurization product gypsum, reducing the cost of desulfurization, and the device is simple in structure and easy to implement .

Owner:XIANGTAN UNIV

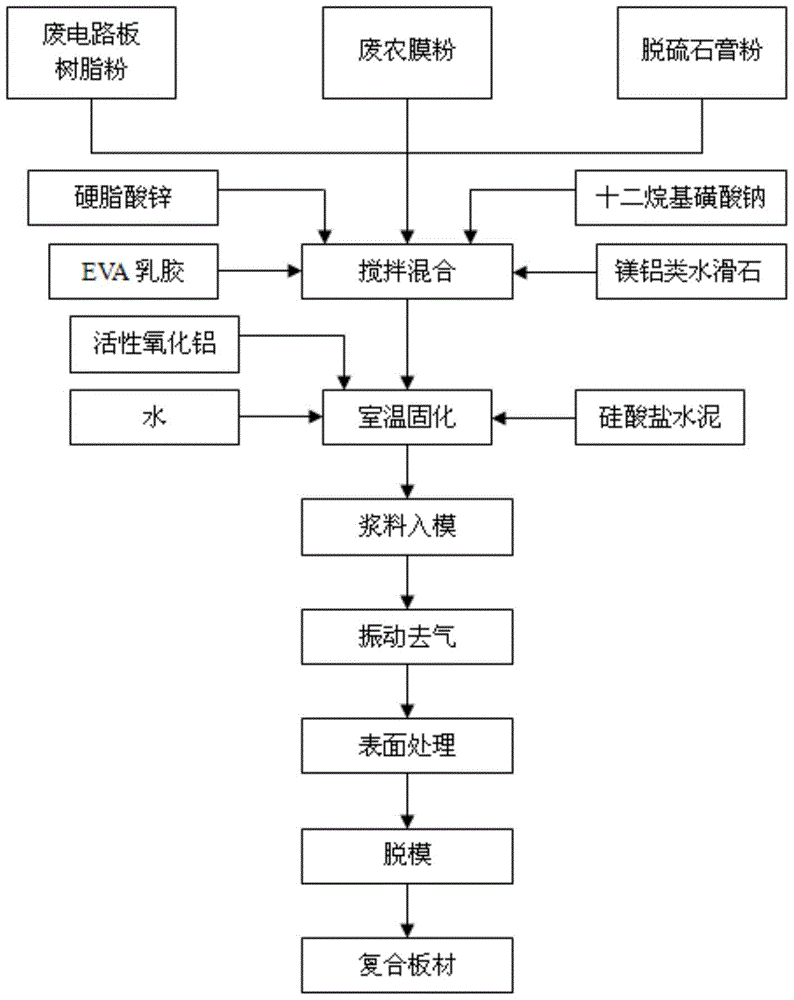

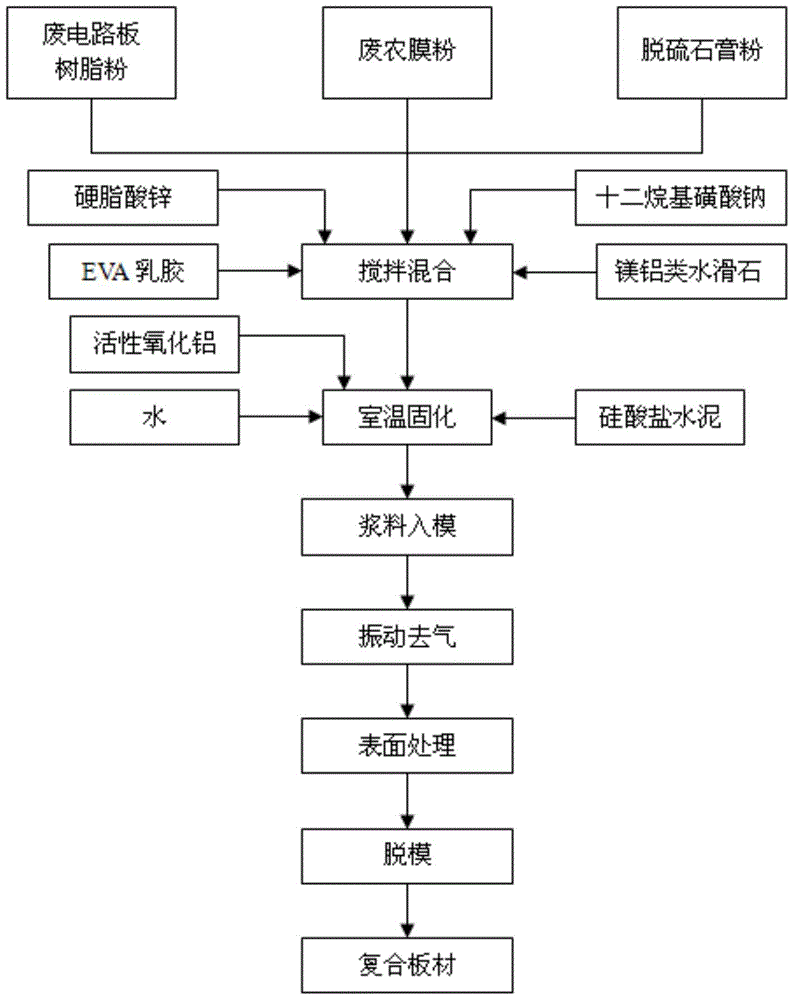

A kind of solid waste recycling treatment method

InactiveCN105731926BReduce pollutionImprove adhesionSolid waste managementRoom temperaturePetroleum coke

The invention provides a solid-waste recycling treating method.The solid-waste recycling treating method includes the steps that surface modifying, inflaming retarding, cement solidifying and strength bonding are carried out, waste circuit board resin powder, waste agricultural film powder and desulphurization gypsum powder are solidified into a composite board at the normal temperature accordingly, and the waste circuit board resin powder with the particle size ranging from 0.5 mm to 5 mm, the waste agricultural film powder with the particle size ranging from 5 mm to 10 mm and the desulphurization gypsum powder with the particle size ranging from 1 mm to 5 mm are subjected to assistant adding, stirred, mixed, solidified at the room temperature, subjected to casting molding, bubble removing and surface treating, demolded and dried to obtain the composite type board.The solid-waste recycling treating method is free of pollution, simple in technology and low in cost, the prepare board is large in practical value, and recycling use of burned petroleum coke dust is achieved.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

A polyionic liquid-based heteropolyacid catalyst for olefin epoxidation, preparation method and application thereof

ActiveCN108465487BIncrease profitMild reaction conditionsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHeteropoly acid

The invention relates to a polyionic liquid-based heteropolyacid catalyst for olefin epoxidation reaction, a preparation method thereof and application thereof, and belongs to the field of chemical catalysis. The preparation method of the catalyst provided by the invention comprises the steps of: adding H3PW12O40 heteropolyacid to a piperidine-functionalized polyionic liquid solution to obtain a white solid particle by ion exchange reaction, and the polyionic liquid-based heteropolyacid catalyst is obtained by filtration, washing and drying of the white solid particle. The obtained catalyst isused in the olefin epoxidation reaction, reaction results are detected by GC, the conversion rate is up to 100%, and the selectivity is up to 97%. The catalyst has the advantages that piperidine-functionalized ionic liquid cations are combined with heteropolyanions, charge transfer in catalyst molecules can be effectively increased, the reaction is accelerated, the yield of an epoxy compound is improved, the catalyst is insoluble in the system in the reaction, and can be reused by simple filtration, and the catalyst has high catalytic activity and long life.

Owner:SOUTHEAST UNIV CHENGXIAN COLLEGE

High-pressure atomizing dielectric barrier discharge plasma water treatment device

ActiveCN103693714BFully degradedImprove decomposition efficiencyWater/sewage treatment by electrochemical methodsWater/sewage treatment by oxidationVapor–liquid separatorHigh pressure water

Owner:CHONGQING UNIV

Acid-base bifunctional solid catalyst for preparing 5-hydroxymethylfurfural and its preparation method and application

InactiveCN108084120BAcid-base strength regulationEasy to manufactureOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystHeteropoly acid

Owner:SHANDONG UNIV OF TECH

Solid-waste recycling treating method

InactiveCN105731926AReduce pollutionImprove adhesionSolid waste managementRoom temperaturePetroleum coke

The invention provides a solid-waste recycling treating method.The solid-waste recycling treating method includes the steps that surface modifying, inflaming retarding, cement solidifying and strength bonding are carried out, waste circuit board resin powder, waste agricultural film powder and desulphurization gypsum powder are solidified into a composite board at the normal temperature accordingly, and the waste circuit board resin powder with the particle size ranging from 0.5 mm to 5 mm, the waste agricultural film powder with the particle size ranging from 5 mm to 10 mm and the desulphurization gypsum powder with the particle size ranging from 1 mm to 5 mm are subjected to assistant adding, stirred, mixed, solidified at the room temperature, subjected to casting molding, bubble removing and surface treating, demolded and dried to obtain the composite type board.The solid-waste recycling treating method is free of pollution, simple in technology and low in cost, the prepare board is large in practical value, and recycling use of burned petroleum coke dust is achieved.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

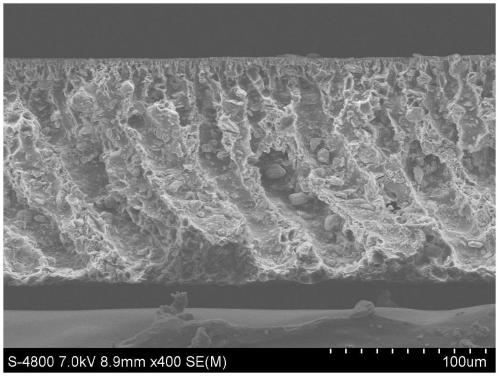

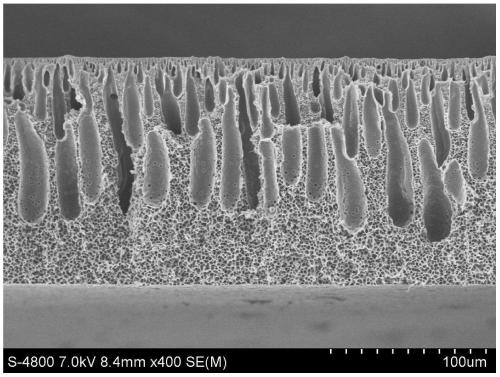

Composite adsorption membrane, preparation method and application thereof

InactiveCN105664879BGood experimental reproducibilitySimple preparation processOther chemical processesWater contaminantsN dimethylformamideWater treatment

The invention provides a composite adsorption film for removing fluorine in water.The composite adsorption film is prepared from, by mass, layered magnesium-aluminum composite hydroxide, a high-molecular polymer and an organic solvent.The high-molecular polymer is preferably one of polyether sulfone, polysulfone and polyvinylidene fluoride.The organic solvent is one of N,N-dimethylacetamide, N,N-dimethylformamide and N-methyl pyrrolidone.The layered magnesium-aluminum composite hydroxide is firmly inlaid in a high-molecular basement membrane, and is not prone to fall off.The composite adsorption film is applied to high-fluorine water treatment, the fluorine content can be reduced to 1 mg / L or below, and the national hygienic standard for drinking water is met.The preparation process is simple, the composite adsorption film can be machined into a film device according to needs, and industrial application can be achieved.

Owner:OCEAN UNIV OF CHINA

A kind of resource processing method of industrial solid waste

The invention provides a method for resourceful treatment of industrial solid waste.Welding dust, straw powder and coal chemical crystalline salt are solidified into a composite plate at normal temperature through surface modification, inflaming retarding and cement solidification, and auxiliary adding, stir-mixing, room temperature curing, casting molding, bubble removal, surface treatment, demolding and drying are conducted on welding dust with particle size smaller than 100 microns, straw powder with particle size being 5-10 micrometers, and coal chemical crystalline salt with particles size being 1-5 micrometers so as to obtain the composite plate.The manufacturing process is free of pollution, the technology is simple, cost is low, the manufactured plate is high in practical value, and resourceful utilization of industrial solid waste is achieved.

Owner:辽宁绿源再生能源开发有限公司

Method for preparing bakelite by using nonmetal material in waste printing circuit board

InactiveCN100467531CProtect resourcesReduce secondary environmental pollutionMetallic materialsPrinted circuit board

The invention discloses a method for preparing bakelite, which uses nonmetallic material of waste printed circuit board as raw material to replace wood powder. The method includes steps: mixing 100 quotient of phenolic resin, 25-75 quotient of waster circuit board nonmetallic material particles, 25-55 quotient of wood powder, 15-20 quotient of curing agent, 10-30 quotient of inorganic filler and 2-6 quotient of lubricant under temperature of 90-110 DEG C, cooling, granulating and obtaining the product. The invention can solve problems of treatment and pollution of waste circuit board nonmetallic material, and can reduce production cost of bakelite.

Owner:SHANGHAI JIAOTONG UNIV

Mesoporous ionic liquid heteropolyacid salt catalyst for benzene hydroxylation reaction and its preparation method and application

InactiveCN107188849BEasy to manufactureHigh catalytic activityOrganic chemistryOrganic compound preparationHydrothermal synthesisPhenol

The invention relates to the technical field of chemical catalysis, in particular to a mesoporous ionic liquid heteropoly acid salt catalyst for benzene hydroxylation reaction, and a preparation method and application thereof. The mesoporous ionic liquid heteropoly acid salt catalyst is prepared by a hydrothermal synthesis method: the H 5 PMo 10 V 2 O 40 The heteropolyacid was added to the xylene-coupled imidazole ionic liquid aqueous solution for reaction, filtered, washed and dried. Then the prepared mesoporous ionic liquid heteropoly acid salt catalyst was used in the reaction of benzene oxidation to phenol. The mesoporous structure hydrophobic microenvironment of the mesoporous ionic liquid heteropolyacid salt catalyst of the present invention improves its catalytic performance and can effectively improve the selectivity of phenol. In addition, the mesoporous ionic liquid heteropoly acid salt catalyst has the advantages of simple preparation, low cost, convenient recovery, stable reusability, fast reaction speed, mild conditions, less environmental pollution, and easy industrialized production.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com