Flexible manometer porous metal foil electrode and preparation method thereof

A nanoporous, metal foil technology, applied in nanotechnology, battery electrodes, chemical instruments and methods, etc., can solve difficult problems such as strength and toughness, and achieve simple preparation methods, solve brittle problems, and high conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

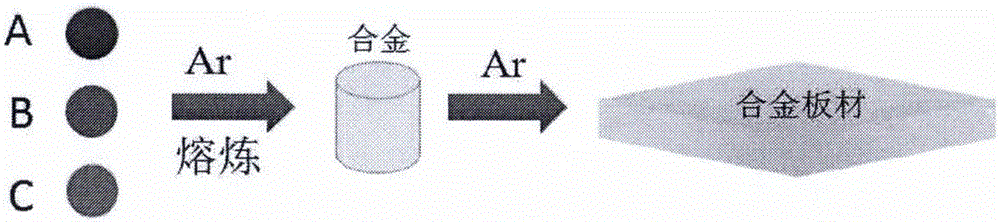

[0027] (1) Preparation of transition metal alloys of different systems

[0028] Select Ni, Cu, Fe, Co, Mo, Mn and other metals as metal masterbatches, and prepare alloys of different systems by powder metallurgy, smelting, etc., among which Fe and Mn, which are easy to corrode, are used as corroded phases and their composition is controlled It is 60at%~70at% (atomic percentage), forming binary alloys or ternary alloys or quaternary alloys, such as binary alloys NiMn, ternary alloys NiCuMn, NiCoMn, NiCoFe and quaternary alloys NiCuCoMn, NiCuFeMn, etc.

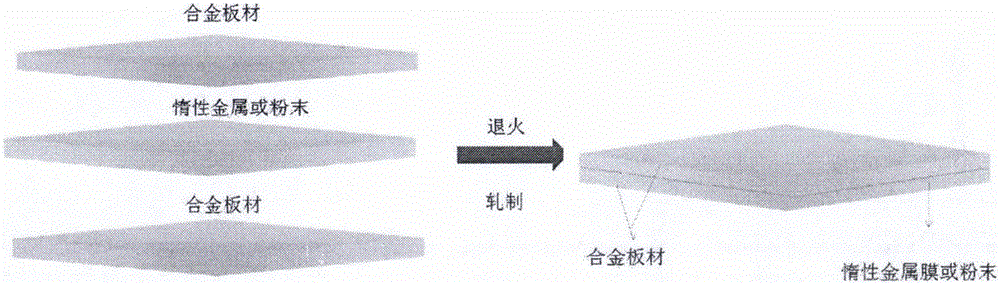

[0029] (2) Selection of interlayer metal

[0030] The interlayer metal should have high inertia, good flexibility and not easy to be corroded. Metals such as Ni or Pt can be selected as the flexible conductive metal layer.

[0031] Among them, the metal content as the corroded phase accounts for 60 at% to 80 at% of the whole.

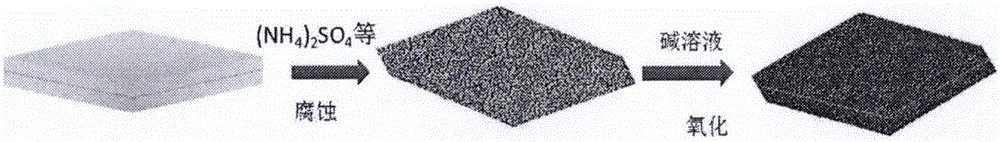

[0032] See Figure 1 to Figure 3 , the preparation method of the flexible nanoporous metal foil ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com