PCBN cutter with nano diamond film coating on surface and preparation method of PCBN cutter

A nano-diamond and thin-film technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of coarse grain size of micro-diamond film, affecting the service life of coating tools, and affecting the quality of diamond film. Achieve the effect of industrial application, good film coating quality and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

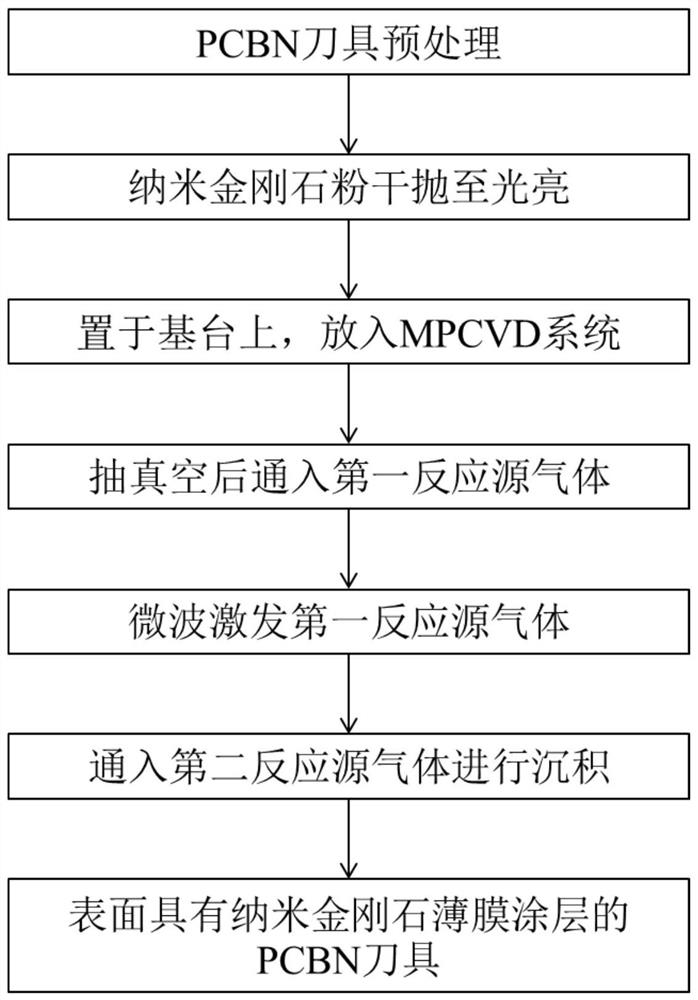

[0056] This embodiment provides a method for preparing a tool with a nano-diamond film coating on the surface, the process flow diagram of the preparation method is as follows figure 1 shown.

[0057] The preparation method comprises the following steps:

[0058] (1) Clean the PCBN tool ultrasonically with acetone for 10 minutes, then dry it at 50°C for 4 minutes, then dry-polish it in diamond powder with a particle size of 100nm for 15 minutes until it is bright, and then place it on a pedestal with a height of 40mm. Put it into the MPCVD system and evacuate to the ultimate vacuum, and then pass H 2 ;

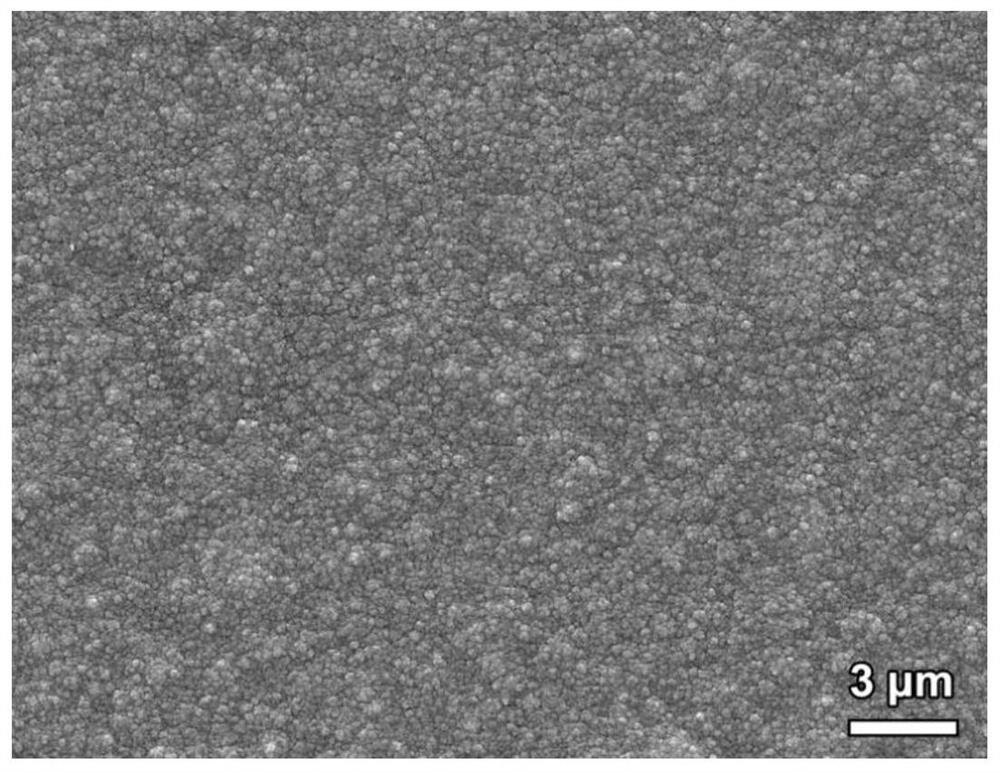

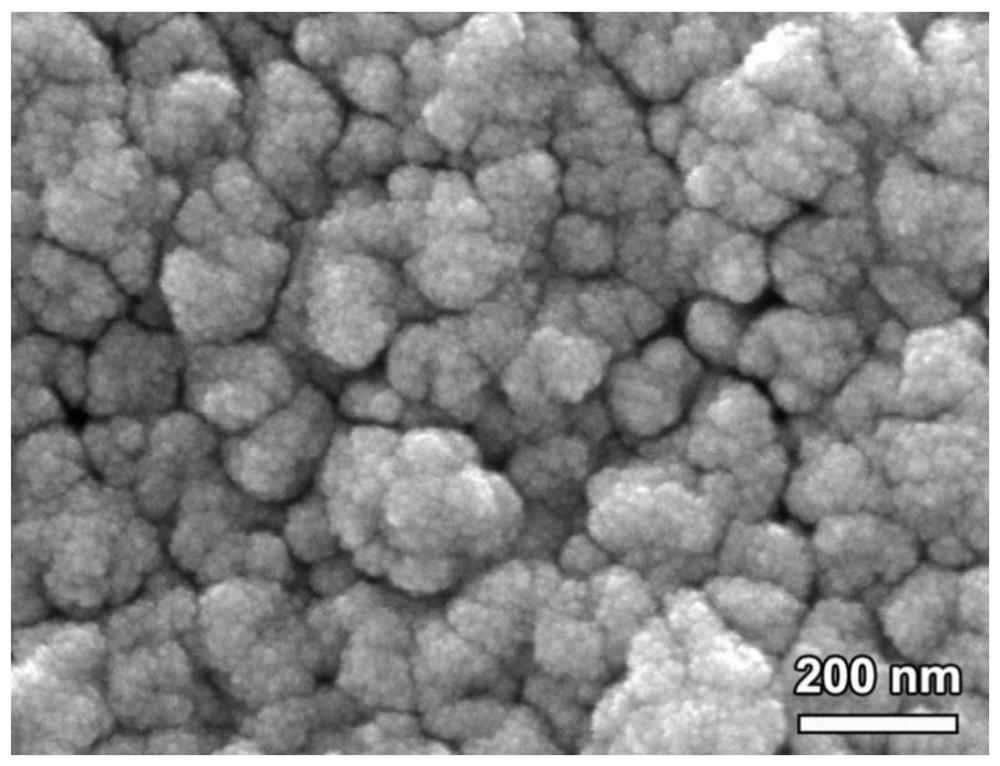

[0059] (2) Turn on the MPCVD system, set the microwave power to 600W, the air pressure in the working chamber to 10Torr, and excite H 2 Generate a plasma ball, and then pass CH 4 begins to deposit, the CH 4 and H 2 The gas flow ratio is 1:50, the microwave power is adjusted to 1500W during the deposition process, the air pressure of the working chamber is 40Torr, the tem...

Embodiment 2

[0067] The present embodiment provides a method for preparing a PCBN cutter with a nano-diamond film coating on the surface, the preparation method comprising the following steps:

[0068] (1) Clean the PCBN tool ultrasonically with acetone for 8 minutes, then dry it at 45°C for 5 minutes, then dry-polish it in diamond powder with a particle size of 10nm for 20 minutes until it is bright, and then place it on a pedestal with a height of 55mm. Put it into the MPCVD system and evacuate to the ultimate vacuum, and then pass H 2 ;

[0069] (2) Turn on the MPCVD system, set the microwave power to 500W, the air pressure in the working chamber to 8Torr, and excite H 2 Generate a plasma ball, then pass CH 4 begins to deposit, the CH 4 and H 2 The gas flow ratio is 4:25, the microwave power is adjusted to 1000W during the deposition process, the air pressure of the working chamber is 20Torr, the temperature of the abutment is 600°C, and the deposition is 12h. After the deposition i...

Embodiment 3

[0071] The present embodiment provides a method for preparing a PCBN cutter with a nano-diamond film coating on the surface, the preparation method comprising the following steps:

[0072] (1) The PCBN tool was ultrasonically cleaned with acetone for 12 minutes, then dried at 45°C for 4 minutes, then dry-polished in diamond powder with a particle size of 500nm for 18 minutes until bright, and then placed on a pedestal with a height of 45mm. Put it into the MPCVD system and evacuate to the ultimate vacuum, and then pass H 2 ;

[0073] (2) Turn on the MPCVD system, set the microwave power to 700W, the air pressure in the working chamber to 12Torr, and excite H 2 Generate a plasma ball, then pass CH 4 begins to deposit, the CH 4 and H 2 The gas flow ratio is 1:100, the microwave power is adjusted to 2000W during the deposition process, the pressure of the working chamber is 60Torr, the temperature of the abutment is 900°C, and the deposition is 6h. After the deposition is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com