Metal organic framework-derived phosphate composite anode material and preparation method thereof

A metal-organic framework and cathode material technology, applied in battery electrodes, active material electrodes, electrochemical generators, etc., can solve the problems of poor kinetic performance of phosphate cathode materials, and improve the specific surface area and electrochemical reactivity , increase porosity, improve the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

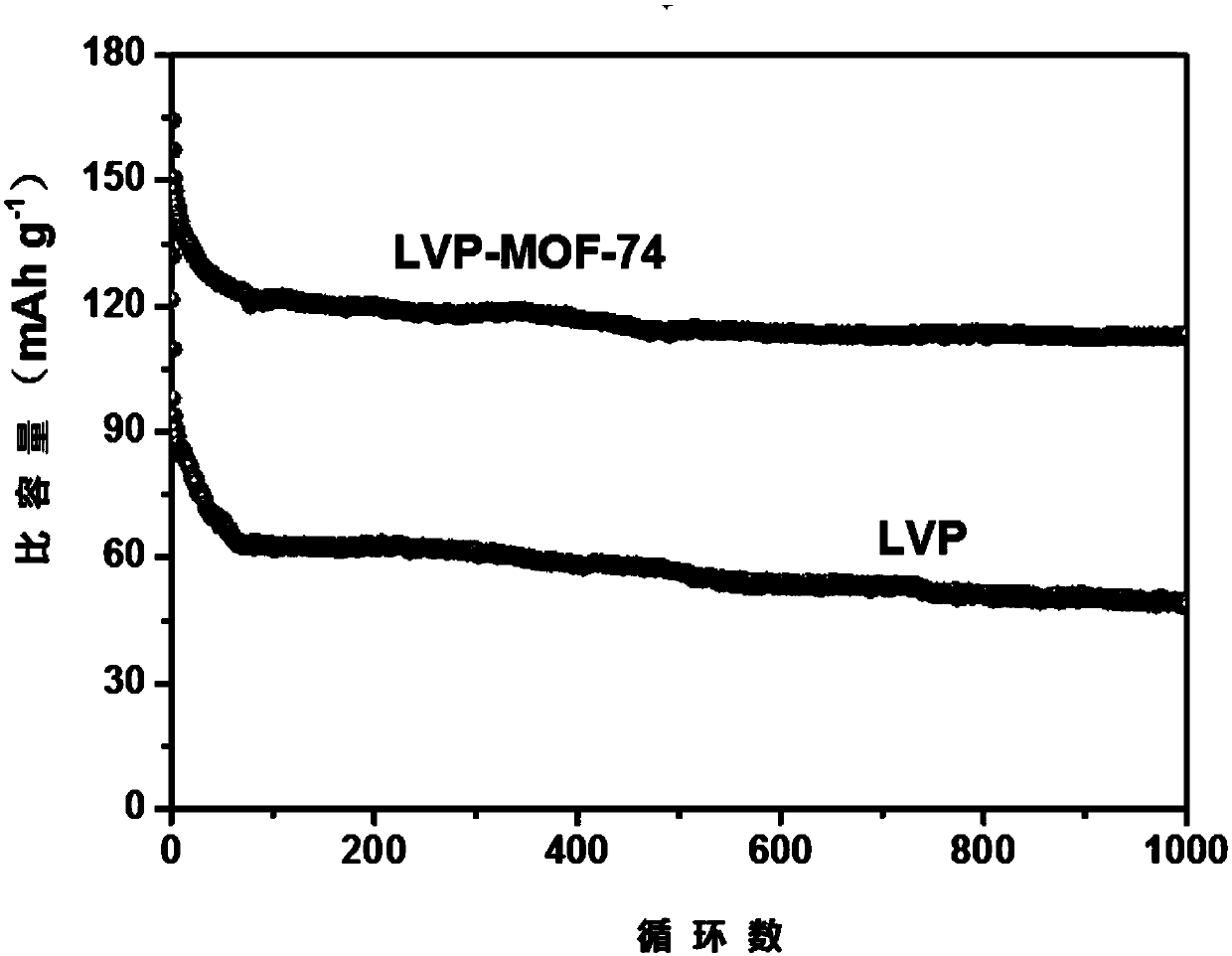

[0030] A kind of preparation method of the phosphate composite cathode material derived from MOF, the chemical formula of described phosphate cathode material is Li 3 V 2 (PO 4 ) 3 -MOF-74, its main preparation steps are as follows:

[0031] (1) H 4 DOBDC and VCl 3 Add it into 60ML ethanol solution according to the stoichiometric ratio of 1:2, stir and mix and ultrasonically disperse for 30 minutes, transfer to a high-temperature reaction kettle, put it in a 110°C oven for 24 hours, wash it with ethanol after cooling, and then put it in DMF solvent , activated under argon atmosphere at 70°C for 3 h, and centrifuged to obtain V-MOF-74.

[0032](2) Using the synthesized V-MOF-74 as the vanadium source and carbon source for the reaction, first calculate the V content through the thermogravimetric analysis TGA curve, and calculate the V content according to the ratio of vanadium and LiOH, NH 4 h 2 PO 4 Mix according to the stoichiometric ratio of 1:1.62:1.5, add acetone fo...

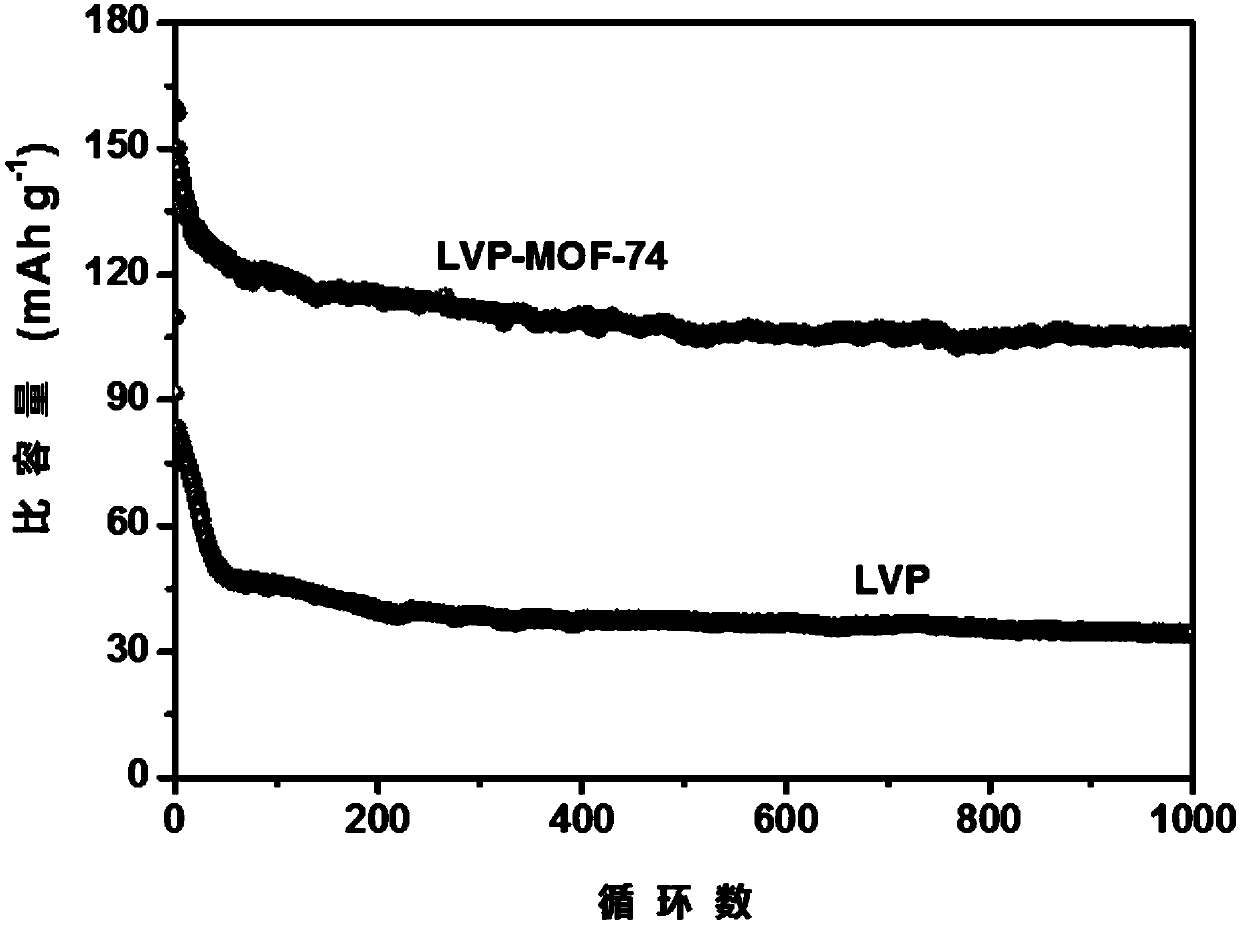

Embodiment 2

[0037] (1) H 2 BDC (15mmol, 98%) and FeCl 3 ·6H 2 O (10mmol, 99%) was added to 60mL DMF solution, stirred and mixed evenly, transferred to a high-temperature reaction kettle, placed in a 150°C oven for 24 hours, after cooling, washed with DMF and ethanol several times, and then placed in a 70°C vacuum oven After drying overnight, Fe-BDC was separated by suction filtration.

[0038] (2) Use the synthesized Fe-BDC as the iron source and carbon source of the reaction, first calculate the iron content through the TGA curve, and compare the moles of Fe with LiOH, NH 4 h 2 PO 4 Mix according to the stoichiometric ratio of 1:1.62:1.5, add acetone for wet ball milling for 2 hours, rotate at 500r / min, and mix well. Afterwards, under an argon atmosphere, the tube furnace was heated to 350°C for 4 hours, ball milled again, and then placed in a tube furnace at 700°C, heated and sintered with argon for 10 hours, and the Fe-MOF derived lithium iron phosphate positive electrode was obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com