Metallic carbon-containing catalyst and preparation method and application thereof

A catalyst and metal technology, applied in the field of metal carbon-containing catalyst and its preparation, can solve the problems of unsuitability for large-scale production, low catalyst life, complicated preparation method, etc., and achieve the effects of improved specific surface area, high catalytic efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The specific embodiment part of the present invention provides a kind of preparation method of metal carbon-containing catalyst, and described preparation method comprises the following steps:

[0054] (1) dissolving at least two transition metal compounds in solvent A to obtain solution a;

[0055] (2) dissolving the imidazole compound in solvent B to obtain solution b;

[0056] (3) Mixing and stirring solution a in step (1) and solution b in step (2), separating solid and liquid, and calcining the obtained precipitate under the protection of an inert gas to obtain a metal carbon-containing catalyst.

[0057] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

Embodiment 1

[0059] A kind of preparation method of metal carbon-containing catalyst, described preparation method comprises the following steps:

[0060] (1) 3g of cobalt nitrate and 0.5g of nickel nitrate are mixed and ground, dissolved in 100mL of methanol to obtain mixed solution a;

[0061] (2) 9g of imidazole was dissolved in 300mL of methanol to obtain solution b;

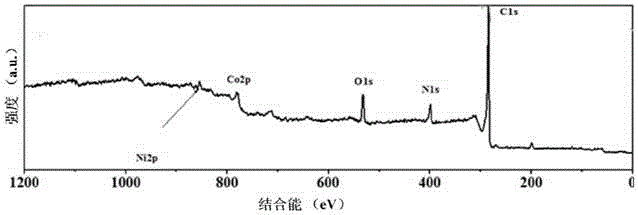

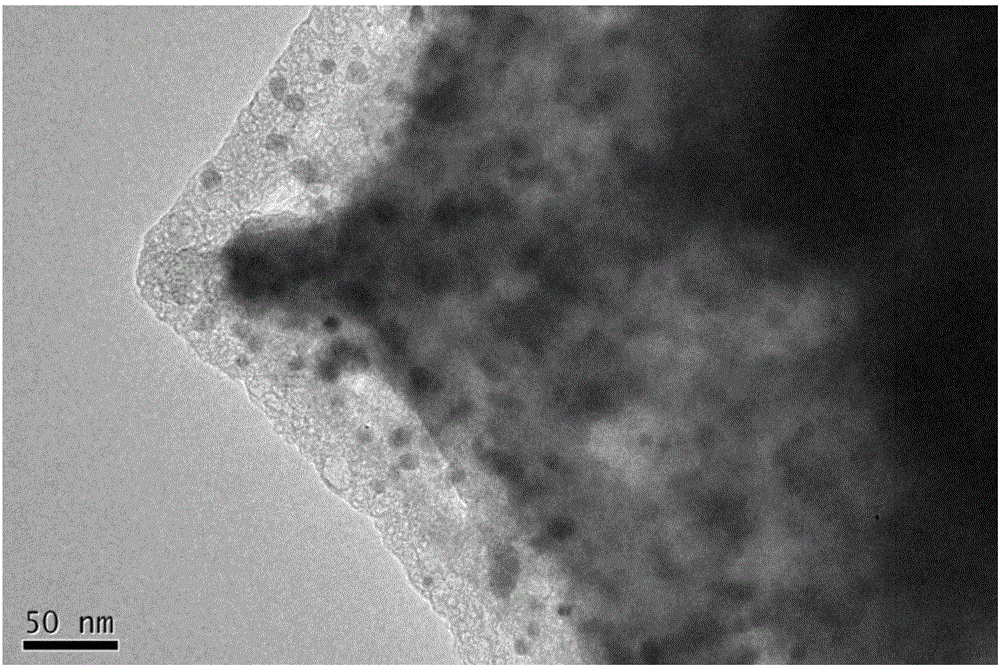

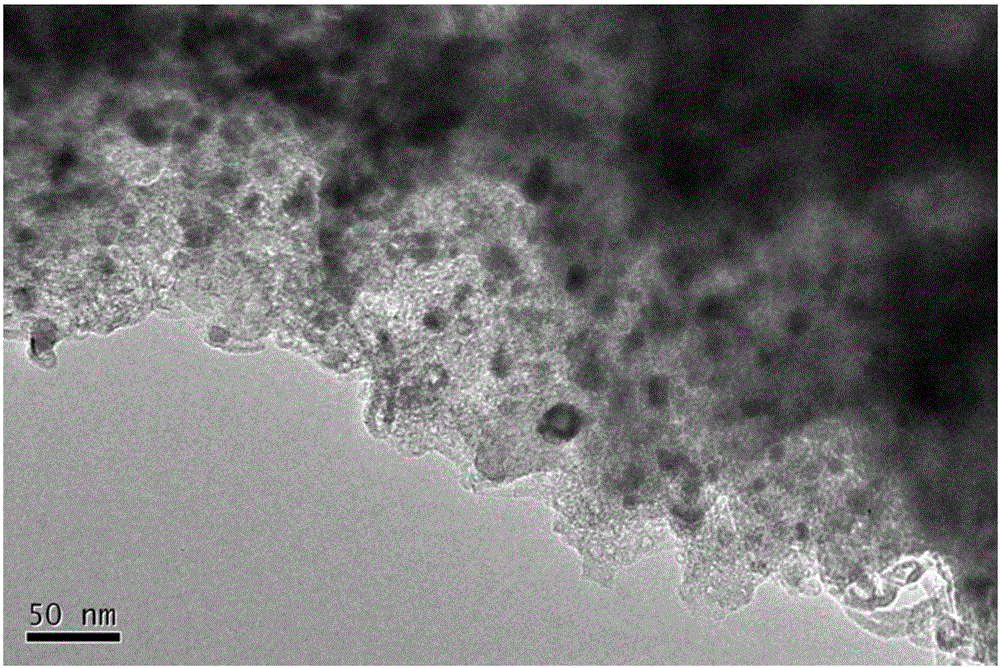

[0062] (3) Mix solution a in step (1) with solution b in step (2), stir at a speed of 100 rpm for 12 hours, then centrifuge at a speed of 10,000 rpm for 5 minutes, collect the precipitate, and calcinate at 900 ° C for 3 hours under nitrogen protection to obtain Co -Ni-N / C catalyst.

Embodiment 2

[0064] A kind of preparation method of metal carbon-containing catalyst, described preparation method comprises the following steps:

[0065] (1) Mix 3 g of cobalt nitrate, 0.5 g of nickel nitrate and 0.5 g of ferrous sulfate, and dissolve them in 200 mL of N,N-dimethylformamide to obtain a mixed solution a;

[0066] (2) 15g of 2-methylimidazole was dissolved in 500mL N,N-dimethylformamide to obtain solution b;

[0067] (3) Mix solution a in step (1) with solution b in step (2), stir at 80 rpm for 24 hours, then centrifuge at 8000 rpm for 10 minutes, collect the precipitate, and calcinate at 800 ° C for 4 hours under the protection of argon to obtain Co-Ni-Fe-N / C catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com