Method for preparing low-temperature nitrogen-doped graphene supported nano Pd hydrogenation catalyst

A technology of nitrogen-doped graphene and hydrogenation catalyst, which is applied in hydrogenation hydrocarbon production, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of uneven particle dispersion, particle loss, and complicated operation, and achieve operational Simple, Gentle, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

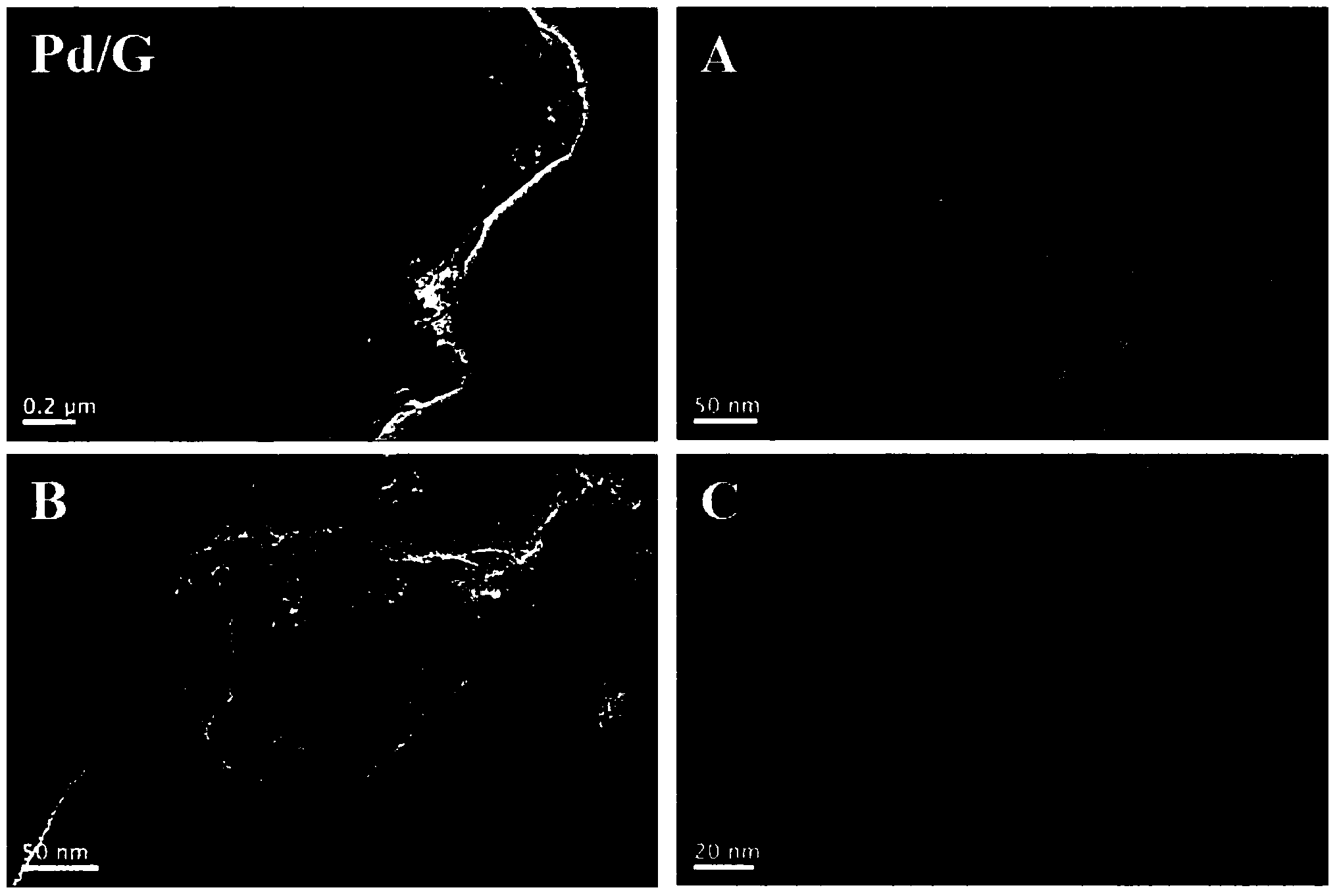

Image

Examples

Embodiment 1

[0020] Weigh graphite oxide and add it to deionized water to make the concentration 2mg / mL, and ultrasonically treat it for 1.5h to obtain a highly dispersed aqueous solution of graphene oxide; add 1.85mmol ethylenediamine to the above solution, stir at room temperature for 10min, and then put it into the hydrothermal reaction In the still, crystallize at 180°C for 12h, suction filter after the crystallization, rinse the sample with deionized water, and dry at 80°C overnight to obtain nitrogen-doped graphene.

[0021] Weigh nitrogen-doped graphene and add it to deionized water (to make the concentration 1mg / mL), sonicate at 50°C for 3h, add 0.4mL PdCl 2 Aqueous solution (0.02mol / L), 1mL hydrazine hydrate was slowly added dropwise while magnetic stirring, stirred at room temperature for 30min, centrifuged, washed 5 times with water, dried in vacuum at 60°C for 2h to obtain the catalyst A.

Embodiment 2

[0023] Weigh graphite oxide and add it to deionized water (to make the concentration 2mg / mL), and ultrasonically treat it for 1.5h to obtain a highly dispersed graphene oxide aqueous solution; add 3.7mmol ammonia water to the above solution, stir at room temperature for 10min, and then put it into the hydrothermal reaction In the still, crystallize at 180°C for 12h, suction filter after the crystallization, rinse the sample with deionized water, and dry at 80°C overnight to obtain nitrogen-doped graphene.

[0024] Weigh nitrogen-doped graphene and add it to deionized water (to make the concentration 1mg / mL), sonicate at 50°C for 3h, add 0.4mL PdCl 2 Aqueous solution (0.02mol / L), 1mL of hydrazine hydrate was slowly added dropwise while stirring magnetically, stirred at room temperature for 30min, centrifuged, washed with water 5 times, and vacuum-dried at 60°C for 2h to obtain the catalyst B.

Embodiment 3

[0026] Weigh graphite oxide and add it to deionized water (to make the concentration 2mg / mL), and ultrasonically treat it for 1.5h to obtain a highly dispersed aqueous solution of graphene oxide; add 1.85mmol urea to the above solution, stir at room temperature for 10min, and then put it into the hydrothermal reaction In the kettle, it was crystallized at 180°C for 12 hours. After the crystallization was completed, it was suction-filtered, rinsed with deionized water, and dried at 80°C overnight to obtain graphene doped with different nitrogen.

[0027] Weigh nitrogen-doped graphene and add it to deionized water (to make the concentration 1mg / mL), sonicate at 50°C for 3h, add 0.4mL PdCl 2 Aqueous solution (0.02mol / L), 1mL hydrazine hydrate was slowly added dropwise while magnetic stirring, stirred at room temperature for 30min, centrifuged, washed with water 5 times, vacuum dried at 60°C for 2h to obtain the catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com