Preparation method of mono-atomic cobalt based nitrogen-sulfur dually-doped carbon material catalyst

A catalyst, double-doping technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as expensive precursors, achieve simple and easy methods, significant cost advantages, and improve dispersion. Effects of Sexual and Intrinsic Activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of precursor

[0030] According to the mass ratio of urea: glucose 60: 1, the total mass of urea glucose: the mass ratio of cobalt chloride hexahydrate is 30: 1, the molar ratio of cobalt chloride hexahydrate: sodium thiocyanide is 1: 2, and the urea is weighed , glucose, cobalt chloride hexahydrate, sodium thiocyanate; the above mixture was dissolved in 30-50mL of absolute ethanol, ultrasonically stirred for 5-10 minutes, placed in a blast drying oven at 40°C-60°C, and dried for 4 ~6h, until the ethanol is completely volatilized, and the mixture is recrystallized in a beaker. Then the recrystallized solid was taken out and placed in a ball mill with a rotation speed of 600rpm-800rpm and a number of turns of 2 to obtain a uniform catalyst precursor of urea, glucose, cobalt chloride hexahydrate and sodium thiocyanate.

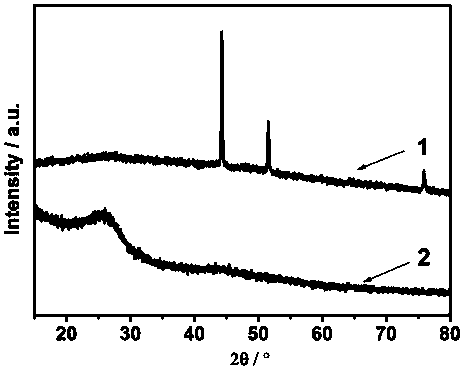

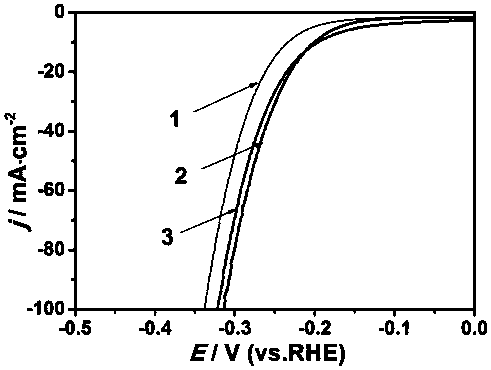

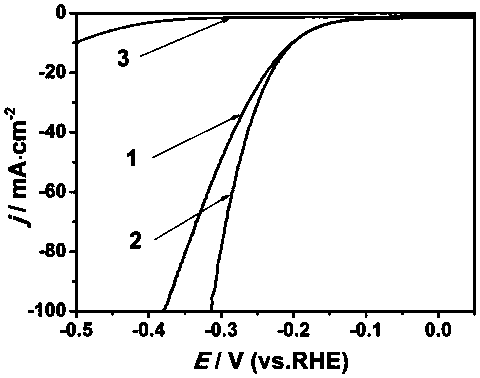

[0031] (2) Preparation of single-atom cobalt-based nitrogen-sulfur double-doped carbon catalyst (CoNSG1)

[0032] First, place the abov...

Embodiment 2

[0037] (1) Preparation of precursor

[0038] According to the mass ratio of urea:glucose 60:1, the mass ratio of urea glucose:cobalt chloride hexahydrate is 240:1, the molar ratio of cobalt chloride hexahydrate:sodium thiocyanate is 1:2, weigh urea, glucose , cobalt chloride hexahydrate, sodium thiocyanate; dissolve the above mixture in 30-50mL of absolute ethanol, stir ultrasonically for 5-10 minutes, place in a blast drying oven at 40°C-60°C, and dry for 4-6h , until the ethanol was completely evaporated, and the mixture was recrystallized in a beaker. Then the recrystallized solid was taken out and placed in a ball mill with a rotation speed of 600rpm-800rpm and a number of turns of 2 to obtain a uniform catalyst precursor of urea, glucose, cobalt chloride hexahydrate and sodium thiocyanate.

[0039] (2) Preparation of single-atom cobalt-based nitrogen-sulfur double-doped carbon catalyst (CoNSG2)

[0040] First, place the above-prepared precursor in a tube furnace, raise ...

Embodiment 3

[0053] (1) Preparation of precursor

[0054] According to the mass ratio of urea:glucose 60:1, the mass ratio of nitrogen-carbon precursor:cobalt chloride hexahydrate is 360:1, the molar ratio of cobalt chloride hexahydrate:sodium thiocyanate is 1:2, and the nitrogen Carbon precursor, cobalt chloride hexahydrate, sodium thiocyanate; dissolve the above mixture in 30-50mL of absolute ethanol, stir ultrasonically for 5-10 minutes, place in a blast drying oven at 40°C-60°C, and dry 4 ~ 6h, until the ethanol is completely volatilized, and the mixture is recrystallized in the beaker. Then the recrystallized solid was taken out and placed in a ball mill with a rotation speed of 600rpm-800rpm and a number of turns of 2 to obtain a uniform catalyst precursor of urea, glucose, cobalt chloride hexahydrate and sodium thiocyanate.

[0055] (2) Preparation of single-atom cobalt-based nitrogen-sulfur double-doped carbon catalyst (CoNSG3)

[0056] First, place the above-prepared precursor i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com