Method for preparing high-nitrogen-content porous carbon material by utilizing biomass, product and application thereof

A high nitrogen-containing, porous carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of difficulty in wide application, high price of nitrogen-doped carbon, difficulty in obtaining nitrogen-doped carbon materials, etc., and achieve low cost. , easy-to-control, simple-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

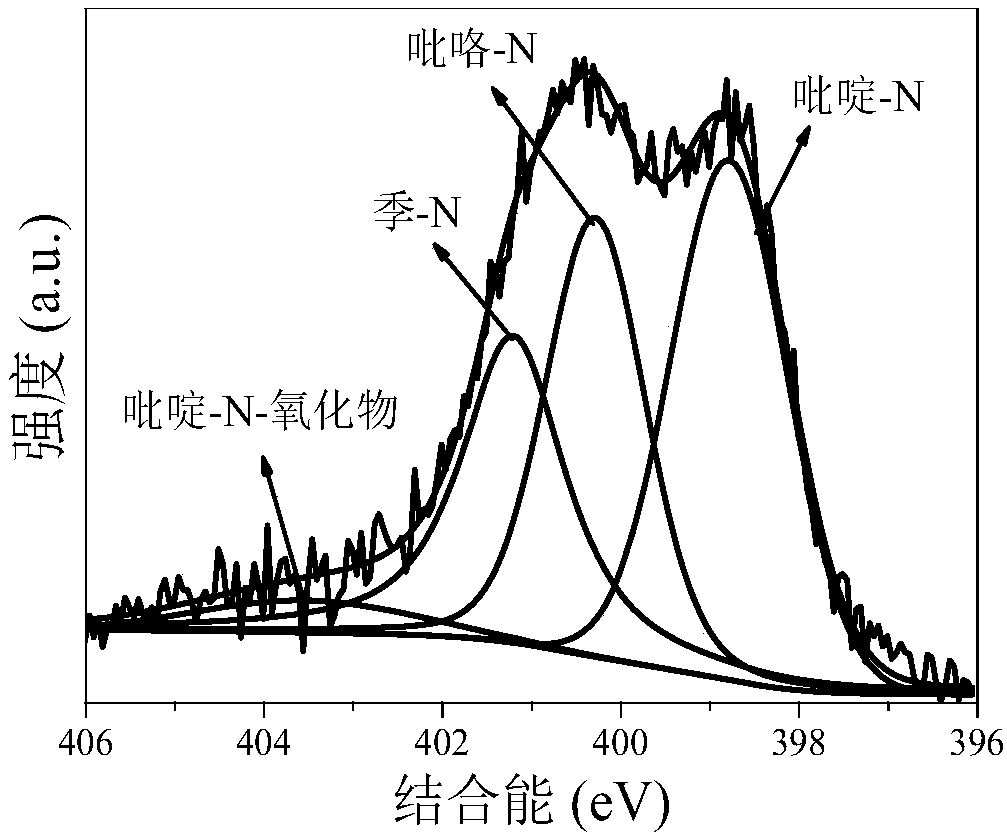

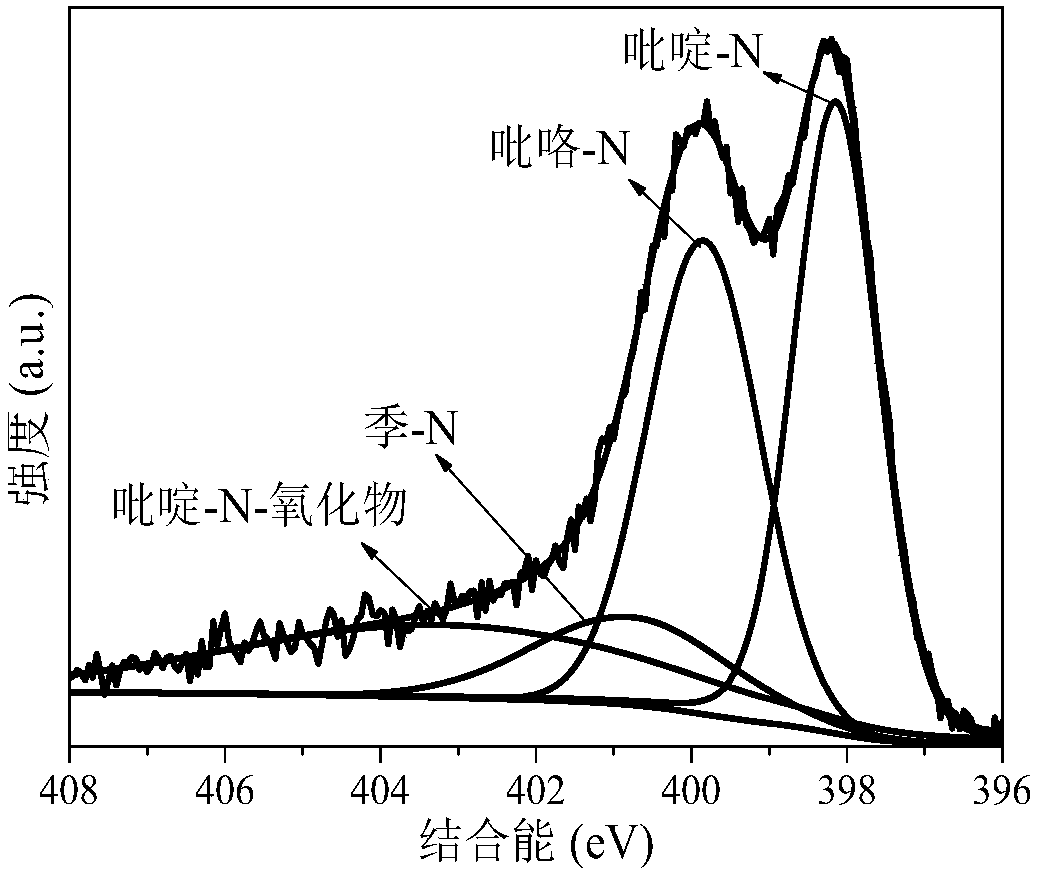

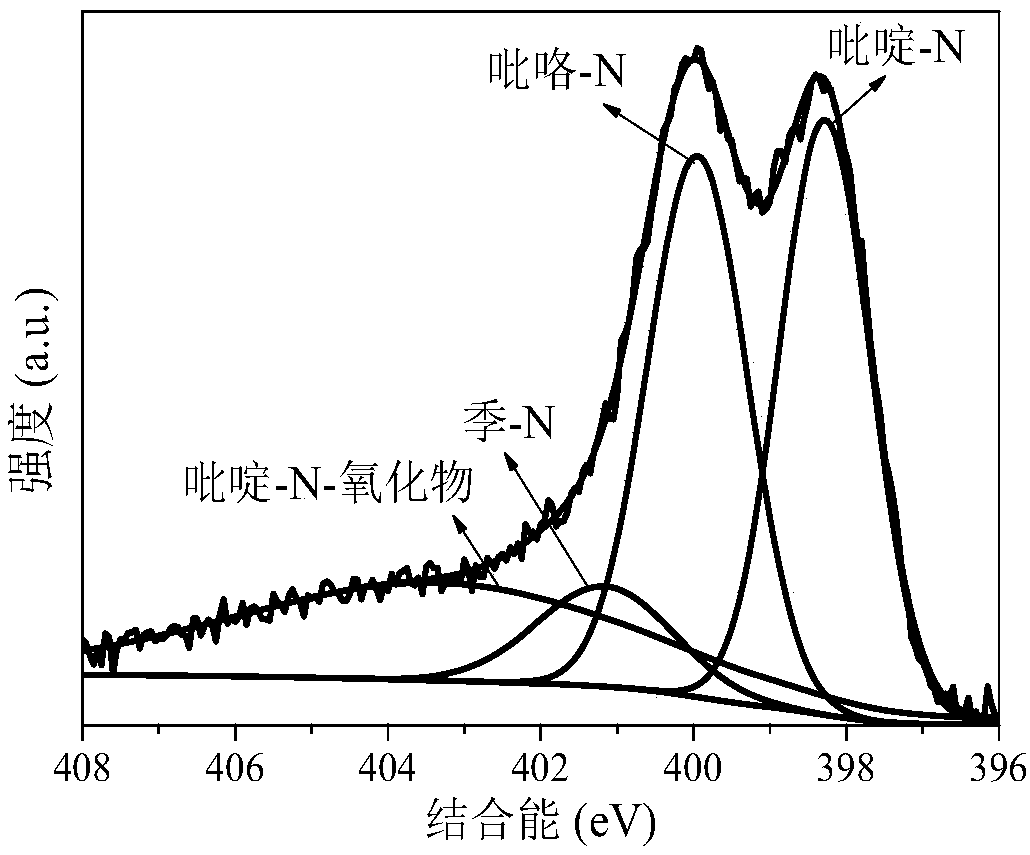

[0039] The embodiment of the present invention describes a method of using biomass to prepare porous carbon materials with high nitrogen content, and the method specifically includes the following steps:

[0040] S1: crush and sieve the bamboo chips to a size less than 120 mesh, put them in an oven at 105°C for 24 hours, and obtain pyrolysis raw materials;

[0041] S2: Fully mix the bamboo chips in step S1 with the KOH activator at a mass ratio of 2:1, use a fixed-bed reactor with a diameter of 45 mm and a length of 60 mm for pyrolysis, and heat the reactor to a nitrogen-enriched pyrolysis temperature of 600 After ℃, 2g of biomass mixture is quickly sent to the middle of the reactor, and the reaction time is 30min to fully decompose the biomass. The total flow rate of argon and ammonia is 200mL / min, and the proportion of ammonia is 10%;

[0042] S3: Pickling the pyrolytic carbon obtained in step S2, the concentration of hydrochloric acid solution is 1mol / L, then filtering and ...

Embodiment 2

[0045] This embodiment is the same as Embodiment 1, except that the activator is NaOH.

[0046] The obtained porous carbon material with high nitrogen content has a well-developed pore structure with a surface area of 1080 m 2 / g, and has abundant active nitrogen-containing functional groups (pyridine-N, pyrrole-N, quaternary-N and pyridine-N-oxide), and the nitrogen content reaches 7wt.%.

Embodiment 3

[0048] This embodiment is the same as embodiment 1, but the activator is K 2 CO 3 .

[0049] The obtained porous carbon material with high nitrogen content has a well-developed pore structure with a surface area of 1150m 2 / g, and has abundant active nitrogen-containing functional groups (pyridine-N, pyrrole-N, quaternary-N and pyridine-N-oxide), and the nitrogen content reaches 12wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com