Composite metal lithium cathode with lithium-carbon composite interface layer and preparation method thereof

A composite metal, interface layer technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of miscellaneous, dangerous, matching, etc., and achieve the effects of improving cycle performance, inhibiting volume deformation, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

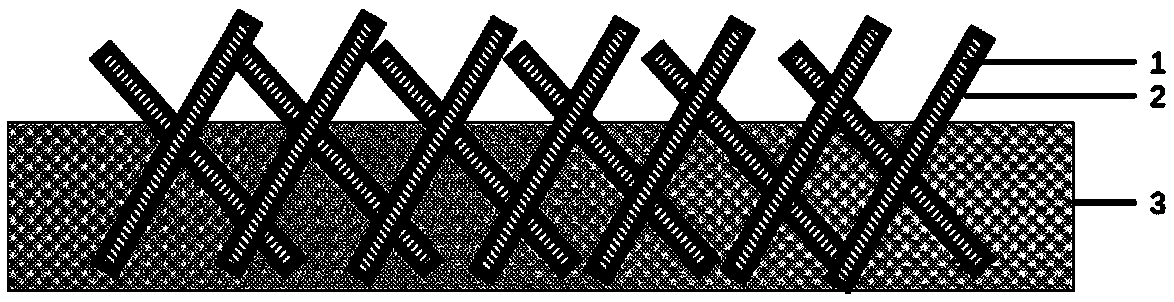

[0025] Its preparation method comprises the following steps:

[0026] 1) Pretreatment of the carbon framework material: the carbon framework material is dehydrated and then contacted with metal lithium;

[0027] 2) Pressurizing the metal lithium bonded or adhered to the carbon framework material, and pressing part or all of the metal lithium into the pores of the carbon framework material to obtain a composite metal lithium negative electrode. 3) The composite lithium metal negative electrode is placed in an environment where the water value is less than 1ppm and the oxygen value is less than 1ppm, and the lithium-carbon composite interface layer is formed outside the carbon skeleton to obtain a composite lithium metal negative electrode with an interface layer.

[0028] The following methods can be used for the pretreatment of the carbon skeleton material in the early stage. The powdery carbon skeleton material is dispersed in water or an organic solvent to prepare a slurry, ...

Embodiment 1

[0031] A kind of carbon paper / lithium strip composite metal lithium negative electrode with lithium-carbon composite interfacial layer, its preparation process is as follows,

[0032] Align and stack the carbon paper (100 μm) and lithium strip (50 μm) after dehydration and drying, and the carbon paper is as figure 2 shown. Rolling is carried out by a rolling mill, the pressure is 6 MPa, and the temperature is 20 degrees Celsius. The composite lithium metal negative electrode after rolling is as image 3 shown. The ultra-thin lithium strips are rolled and embedded in the interstices of the carbon fibers.

[0033] After rolling, the composite metal lithium negative electrode was placed in a glove box with a water value of less than 0.1ppm and an oxygen value of less than 0.1ppm for 48h and 108h, respectively, at a temperature of 20 degrees Celsius. From Figure 4 It can be seen that after standing for 72 hours, the pressed metal lithium adheres better to the carbon paper. ...

Embodiment 2

[0036] A Ketjen black / lithium strip composite metal lithium negative electrode with a lithium-carbon composite interface layer, the preparation process of which is as follows:

[0037] Add Ketjen black to ultrapure water to make a slurry, and use a coating machine to coat the slurry on copper foil (referred to as carbon-coated copper foil), and dry it in a vacuum oven at 60 degrees Celsius for 6 hours for later use.

[0038] Align and stack the lithium strip (100 μm) and the carbon-coated copper foil (the carbon layer of the carbon-coated copper foil is placed towards the ultra-thin lithium strip), and roll it through a roller press with a rolling pressure of 20 MPa and a temperature of 50 degrees Celsius.

[0039] After rolling, the copper foil on the upper layer is peeled off (the Ketjen black carbon layer sticks to the surface of the ultra-thin lithium strip after rolling), and the ultra-thin lithium strip / Ketjen black composite metal lithium negative electrode is obtained, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com