Preparing method of lithium ion battery silicon carbon negative electrode material

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems that hinder the industrial production of silicon/carbon composite materials, and achieve mild conditions and electric The effect of improved chemical properties and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Disperse 0.5g of 50-80nm silicon powder in 100mL of deionized water by ultrasonication, add 5g of polydiallyldimethylammonium chloride, after ultrasonication for 2 hours, centrifuge, wash with water 3 times, vacuum at 70°C After drying for 10 hours, polymer-modified silicon nanoparticles (Si-PDDA) were obtained.

[0026] (2) Add 2g of 10-12um mesophase carbon microspheres to 90mL of a mixture of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 3:1, stir and reflux at 70°C for 10 hours, wash with water until neutral, and then dry to obtain oxidized Mesophase carbon microspheres (O-MCMB).

[0027] (3) Add 0.1g Si-PDDA to the mixture of 45ml ethanol and 5mL water, ultrasonically disperse, add 0.7gO-MCMB, stir ultrasonically for 1 hour, add 10mL 0.05g / mL sucrose aqueous solution, stir and evaporate the solvent in a water bath at 70°C.

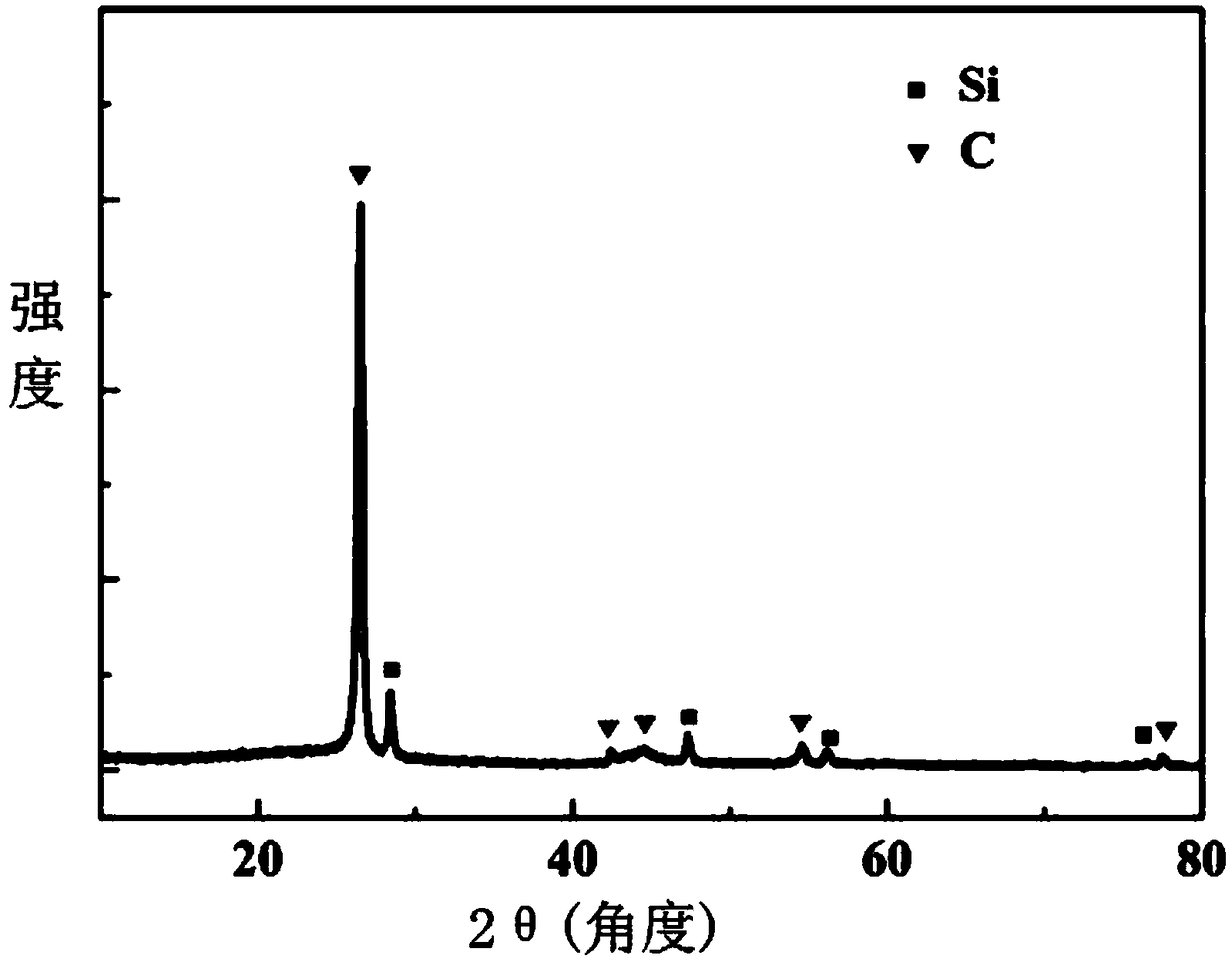

[0028] (4) Put the dried sample into an argon-protected tube furnace for calcination at 700° C. for 2 ho...

Embodiment 2

[0034] (1) Disperse 0.5g of 200nm silicon powder in 100mL of deionized water by ultrasound, add 3mL of aminopropyltriethoxysilane, stir for 2 hours, centrifuge, wash with water 3 times, and vacuum dry at 70°C for 10 hours to obtain a polymer material-modified silicon nanoparticles (Si-APTMS).

[0035] (2) Add 2g10-12um mesocarbon microspheres and 1.5g sodium dodecyl sulfate into 80mL water, stir for 2 hours, centrifuge, and dry to obtain mesophase carbon microspheres modified by sodium dodecyl sulfate (MCMB- SDS).

[0036] (3) Add 0.15g of Si-APTMS to the mixture of 45ml of ethanol and 5mL of water, after ultrasonic dispersion, add 0.7g of MCMB-SDS, ultrasonic for 1 hour, and add 10mL of 0.05g / mL glucose solution. Stir in a water bath at 70°C and evaporate the solvent to dryness.

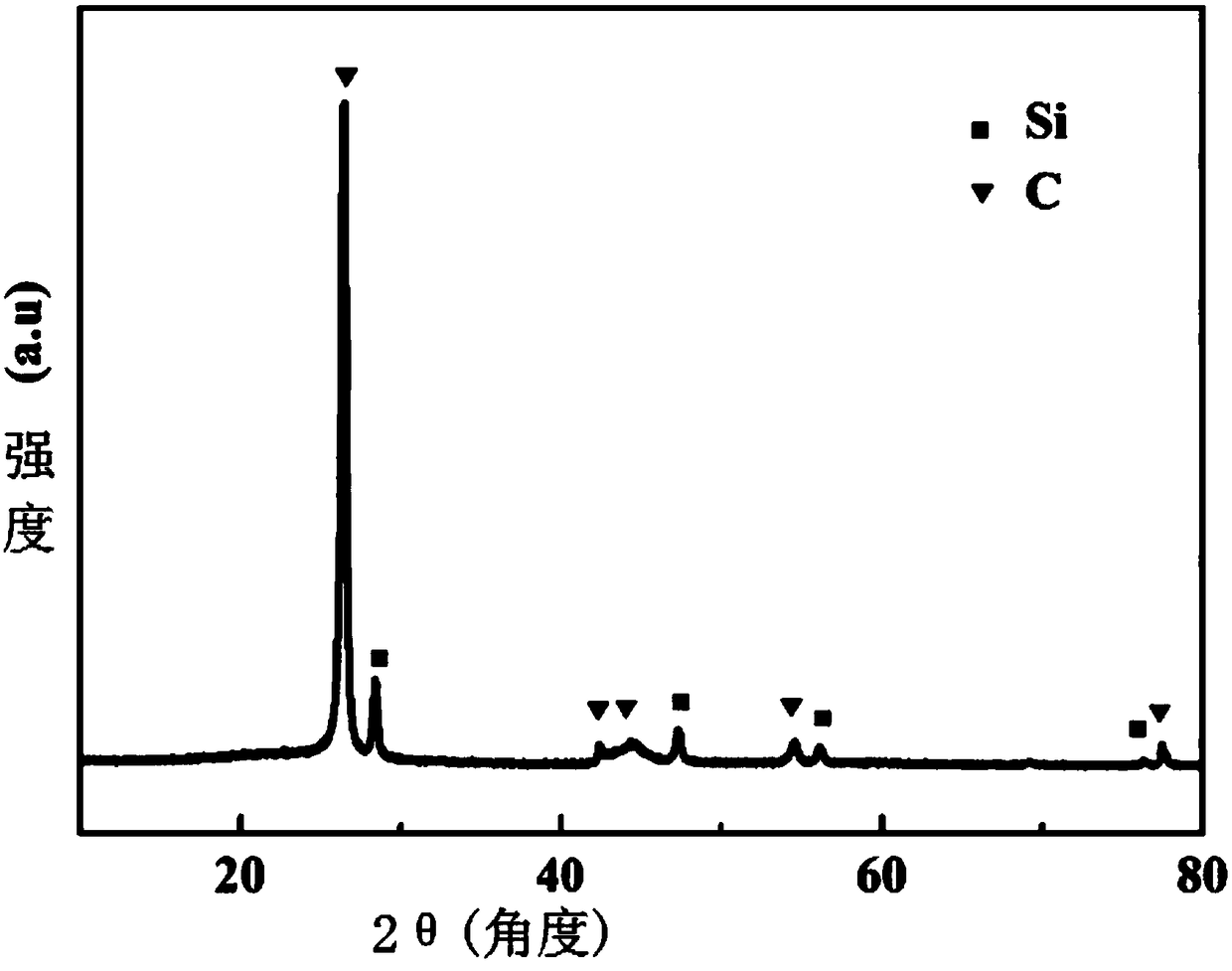

[0037] (4) Put the dried sample into an argon tube furnace for calcination at 800° C. for 3 hours to obtain the final product.

[0038] Figure 5 It is the scanning electron microscope picture of ...

Embodiment 3

[0041] (1) Disperse 0.5g of 500nm silicon powder in 100mL of deionized water by ultrasound, add 2g of hexadecyltrimethylammonium bromide, ultrasonic for 2 hours, centrifuge, wash with water 3 times, and vacuum dry at 70°C for 10 hours. Polymer-modified silicon nanoparticles (Si-CTAB) were obtained.

[0042] (2) Add 10-12um mesocarbon microspheres into 0.5M alkaline potassium permanganate solution, stir for 24 hours, wash with water until neutral and dry to obtain oxidized mesocarbon microspheres (O-MCMB).

[0043] (3) Add 0.2g of Si-CTAB to a mixture of 45ml of ethanol and 5mL of water, and after ultrasonic dispersion, add 0.7g of O-MCMB, stir for 3 hours, and add 0.2g of phenolic resin. Stir in a water bath at 70°C and evaporate the solvent to dryness.

[0044] (4) Put the dried sample into an argon tube furnace for calcination at 500° C. for 8 hours to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com