Method for preparing supported nano-cobalt catalyst by pyrolysis of deep eutectic solvent and application

A low eutectic solvent, supported technology, used in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. Good application value and prospect, high activity, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

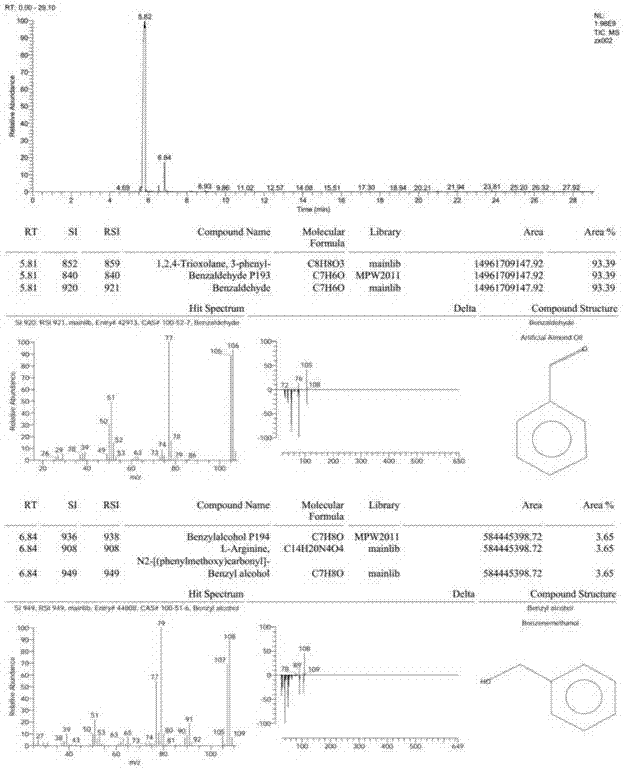

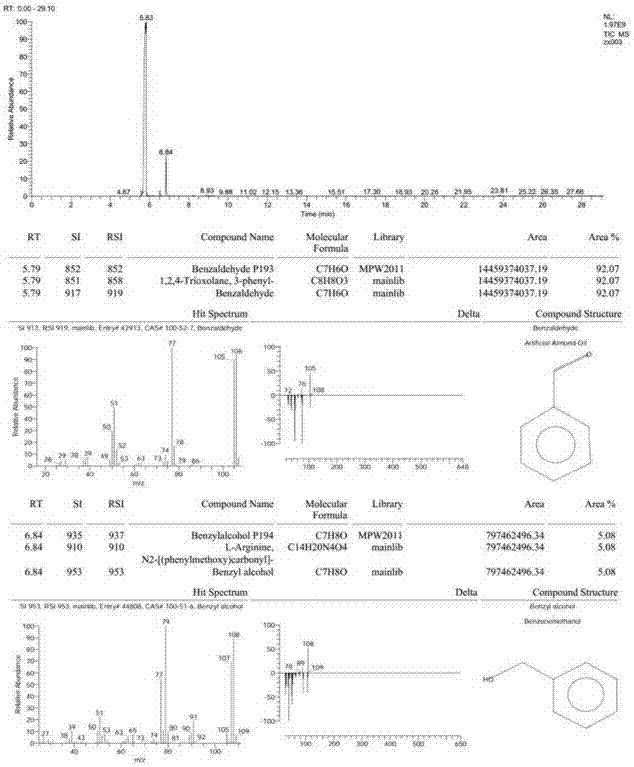

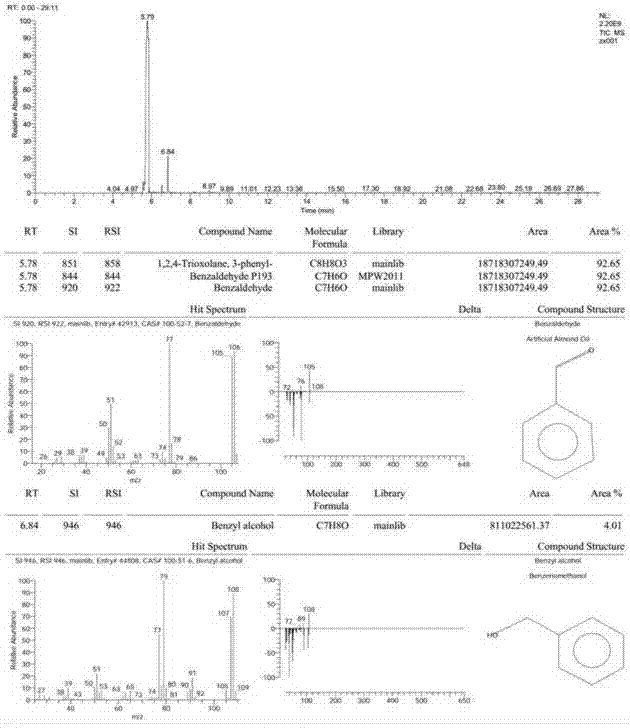

Image

Examples

Embodiment 1

[0023] At room temperature, in the reactor, add 1-butyl-3-methylimidazolium bromide ([Bmim]Br) 4.38g (2.0mmol) and Co(NO 3 ) 2 ·6H 2 O 1.83g (1.0mmol), stirred and mixed 25 minutes, obtained cobalt-containing deep eutectic solvent; Continue to add 2.0g carbon black and 40g solvent ethanol to reactor, stir and mix 80 minutes and evenly disperse solid-liquid mixture, after removing solvent, obtain A carbon black mixture loaded with a deep eutectic solvent; put the prepared mixture into a tube furnace, and heat up and pyrolyze it under an argon protective atmosphere, starting from an initial temperature of 50°C, with a heating rate of 5°C / min , raised the temperature to 700°C, kept at 700°C for 2 hours, then cooled to room temperature by program, and obtained the residue after pyrolysis. The residue was washed and dried with water to obtain a supported nano-cobalt catalyst, which was named Co-N-C-1.

Embodiment 2

[0025] At room temperature, 2.93 g (2.0 mmol) of 1-ethyl-3-methylimidazolium chloride ([Emim]Cl) and Co(NO 3 ) 2 ·6H 2 O 1.83g (1.0mmol), stirred and mixed 20 minutes, obtained cobalt-containing deep eutectic solvent; Continue to add 2.5g carbon black and 40g solvent ethanol to reactor, stir and mix 90 minutes and evenly disperse solid-liquid mixture, after removing solvent, obtain A carbon black mixture loaded with a deep eutectic solvent; put the prepared mixture into a tube furnace, and heat up and pyrolyze it under a nitrogen protective atmosphere, starting from an initial temperature of 50°C, with a heating rate of 10°C / min, Raise the temperature to 750°C, keep the temperature at 750°C for 2 hours, then cool down to room temperature by program, and obtain the residue after pyrolysis. The residue is washed and dried with water to obtain the supported nano-cobalt catalyst, which is named Co-N-C-2.

Embodiment 3

[0027] At room temperature, in the reactor, add 1-hexyl-3-methylimidazolium bromide ([Hmim]Br) 4.94g (2.0mmol) and Co(NO 3 ) 2 ·6H 2 O 1.83g (1.0mmol), stirred and mixed 30 minutes, obtained cobalt-containing deep eutectic solvent; Continue to add 2.0g carbon black and 40g solvent methanol to reactor, stir and mix 60 minutes and evenly disperse solid-liquid mixture, after removing solvent, obtain A carbon black mixture loaded with a deep eutectic solvent; put the prepared mixture into a tube furnace, and heat up and pyrolyze it under an argon protective atmosphere, starting from an initial temperature of 50°C, with a heating rate of 5°C / min , raised the temperature to 800°C, kept at 800°C for 2 hours, then cooled to room temperature by program, and obtained the residue after pyrolysis. The residue was washed and dried with water to obtain a supported nano-cobalt catalyst, which was named Co-N-C-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com