Nitrogen-doped three-dimensional graphene catalyst and preparation method thereof

A graphene and nitrogen doping technology, applied in electrical components, battery electrodes, circuits, etc., can solve difficult modification and processing problems, achieve the effect of improving catalytic performance and overcoming process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Nitrogen-doped three-dimensional graphene was prepared by hydrothermal method.

[0030] Concrete preparation steps are as follows:

[0031] 1) Add 0.1 g of GO to 10 mL of deionized water to prepare a GO dispersion with a mass concentration of 10 mg / mL.

[0032] 2) Add 0.15g of melamine and 0.27mL of formaldehyde solution (37wt%) to the above GO dispersion at a molar ratio of 1:3, stir and sonicate evenly.

[0033] 3) Transfer the above mixed solution to an autoclave for reaction at 180° C. for 12 hours to obtain a three-dimensional graphene mixed solution with melamine formaldehyde resin.

[0034] 4) The above mixed solution was washed three times with deionized water, and dried under vacuum at 80° C. for 20 h. Three-dimensional graphene with melamine formaldehyde resin was obtained.

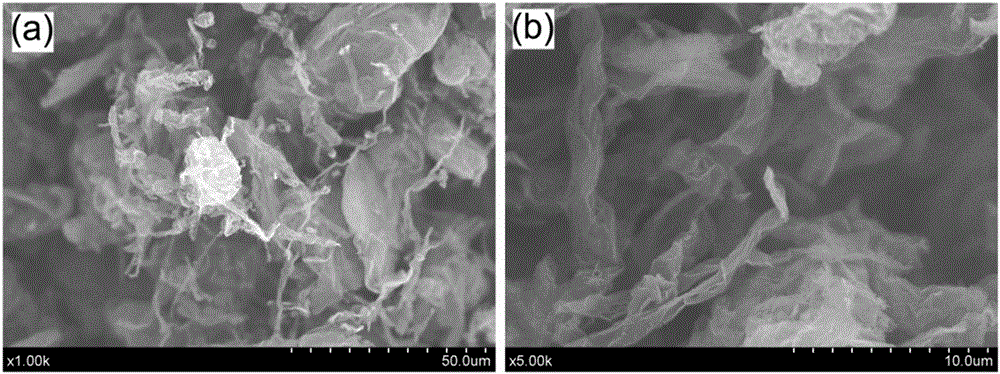

[0035] The morphology of the nitrogen-doped three-dimensional graphene obtained from melamine-formaldehyde resin was characterized by scanning electron microscopy.

[0036] figure 1 ...

Embodiment 2

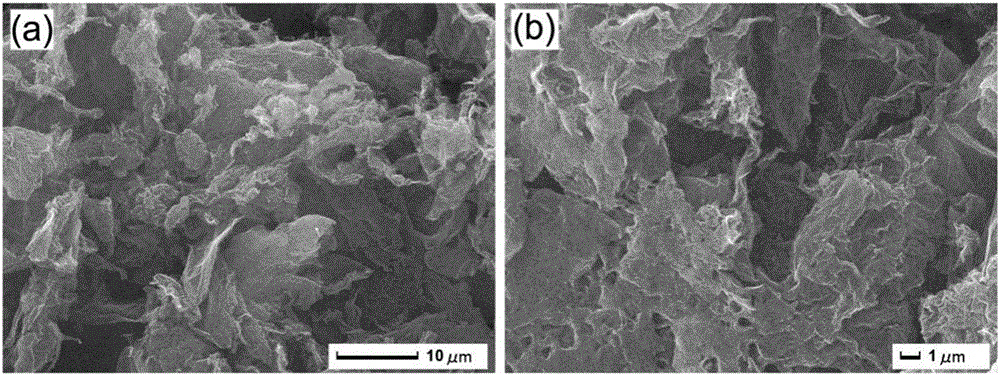

[0038] The steps in Example 2 are similar to those in Example 1, and the other reaction conditions remain the same, except that step 5) is obtained by heat-treating the three-dimensional graphene of melamine formaldehyde resin obtained by vacuum drying at 750 ° C for 5 h under an argon protective atmosphere to obtain N-3DrGO . figure 2 Obtain the SEM figure of N-3DrGO for embodiment 2, as can be seen from the figure figure 1 The blocky melamine formaldehyde resin in it has disappeared, indicating that high temperature heat treatment can decompose it, and figure 2 In b, it can be seen that there are small hole structures in the three-dimensional graphene sheets.

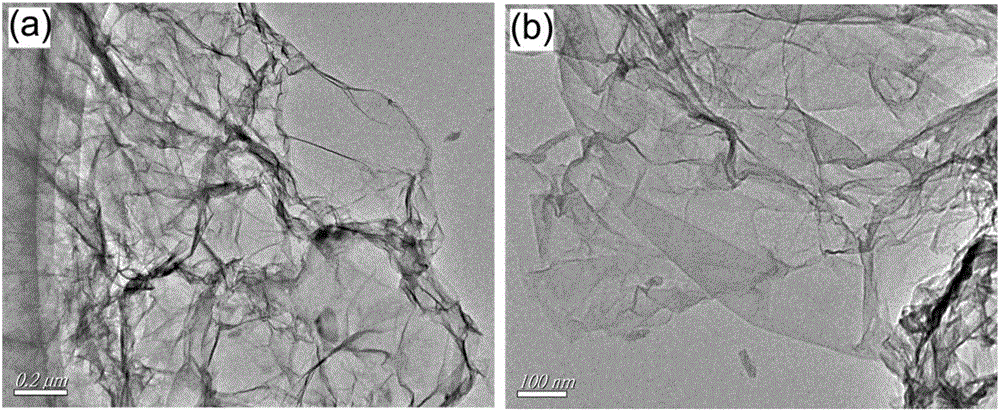

[0039] image 3 It is the TEM figure of N-3DrGO obtained in embodiment 2, from image 3 In a, it can be seen that there are obvious wrinkles and network structures on the graphene sheet, and from image 3In b, it can be seen that the graphene sheet is quite different from the GO sheet, and there are certain gaps...

Embodiment 3

[0041] The steps of embodiment 3 are similar to those in embodiment 2, except that the amount of melamine in step 2) is changed to 0.35g, the mass ratio of GO and melamine becomes 1:3.5, and the amount of formaldehyde solution (37wt%) is changed to 0.63mL, keeping The molar ratio of melamine and formaldehyde 1:3 was not changed, and other reaction conditions were not changed.

[0042] Figure 4 It is the specific surface area and pore size distribution figure of N-3DrGO obtained in embodiment 3, as can be seen from the figure, this N-3DrGO has a higher specific surface area (402.6m 2 / g) and pore size distribution dominated by mesopore distribution, with an average pore size of 0.517cm 3 / g.

[0043] Figure 5 Be the XPS energy spectrogram of N-3DrGO obtained in embodiment 2, from Figure 5 In a, it can be seen that N-3DrGO has a N1s peak at 399.5eV, indicating that three-dimensional graphene has achieved nitrogen doping (elemental analysis results show that the nitrogen d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com