Self-respiration type fuel battery membrane electrode and method for producing the same

A fuel cell membrane and self-breathing technology, which is applied in the direction of fuel cells, battery electrodes, fuel cell components, etc., can solve the problems of membrane electrode influence, high contact resistance, and affecting the performance of membrane electrode work, so as to improve performance , The effect of resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

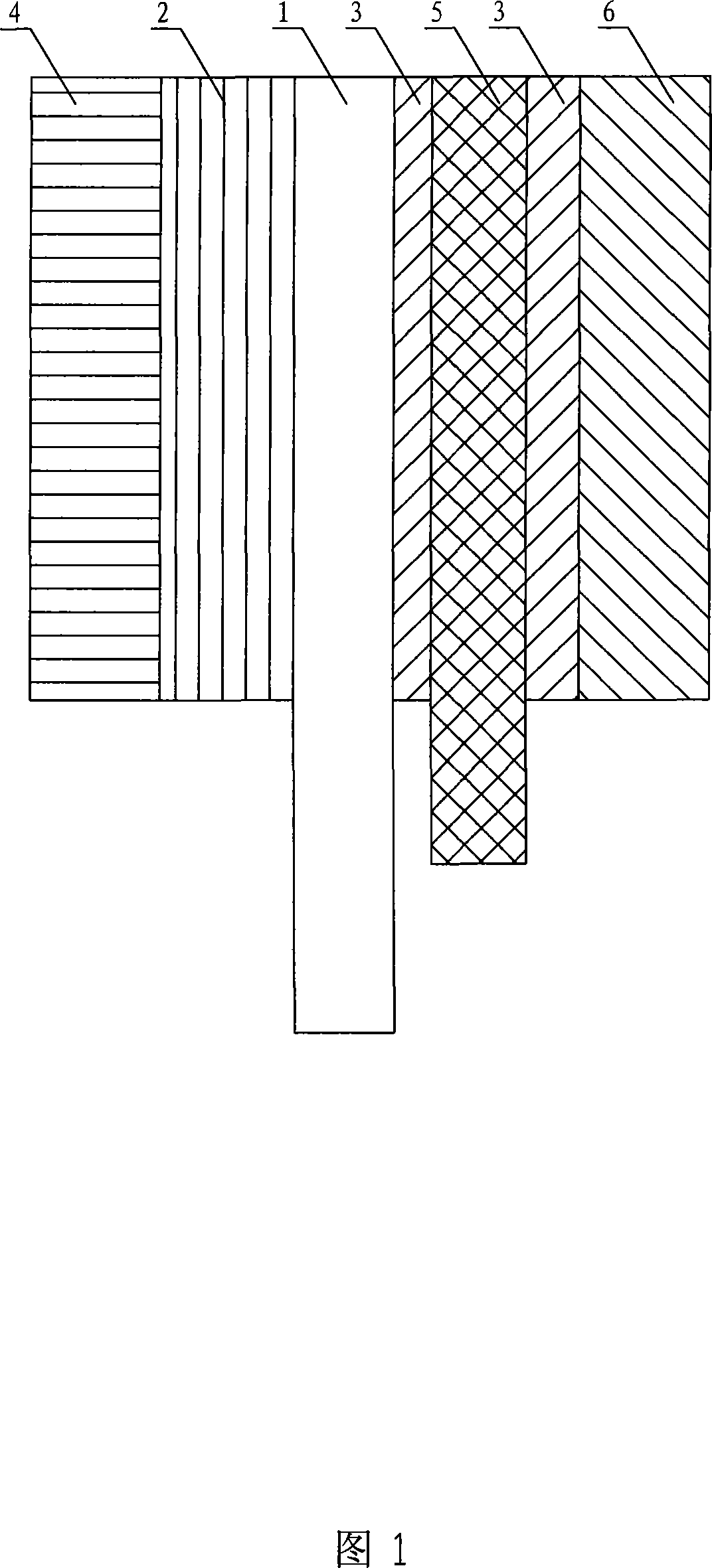

[0023] Specific implementation manner 1: This implementation manner is described in conjunction with FIG. 1 . This embodiment consists of a proton exchange membrane 1, an anode catalyst layer 2, a cathode catalyst layer 3, an anode diffusion layer 4, a porous metal mesh current collector 5, and a cathode diffusion layer 6. The porous metal mesh collector 5 is vertically arranged on the cathode catalyst Inside the layer 3, the anode catalytic layer 2 is arranged on the left side of the proton exchange membrane 1, the cathode catalytic layer 3 is arranged on the right side of the proton exchange membrane 1, the left side of the anode catalytic layer 2 is provided with an anode diffusion layer 4, and the cathode catalytic layer The right side of 3 is provided with cathode diffusion layer 6, proton exchange membrane 1, anode catalyst layer 2, cathode catalyst layer 3, anode diffusion layer 4, porous metal mesh current collector 5 and cathode diffusion layer 6 are hot-pressed and so...

specific Embodiment approach 2

[0026] Embodiment 2: The lead wire in this embodiment is connected to the protruding end of the porous network current collector 5 . Draw the current out.

specific Embodiment approach 3

[0027] Embodiment 3: The anode diffusion layer 4 and the cathode diffusion layer 6 of this embodiment are coated with polymer slurry on carbon paper or carbon cloth (the carbon paper or carbon cloth is produced by Toray Corporation of Japan).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com