Application of modified calcium carbonate in plastics

A calcium carbonate and modified technology, applied in the field of plastic preparation, can solve the problems of tensile strength, bending strength, Brinell hardness difference, etc., and achieve the effects of excellent tensile strength, high thermal deformation temperature and excellent effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

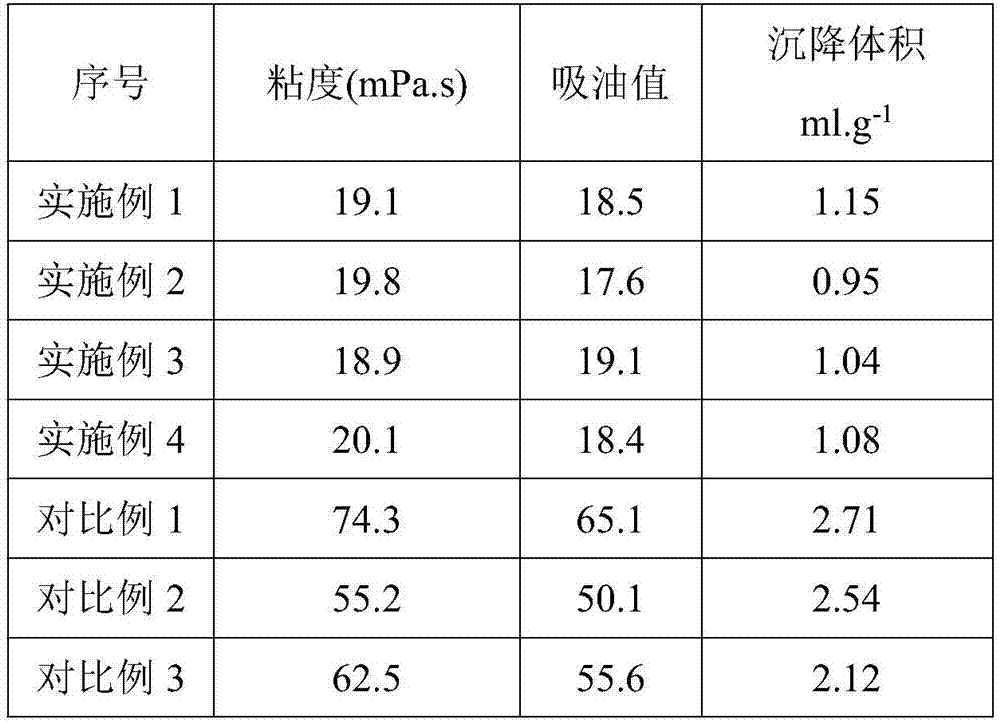

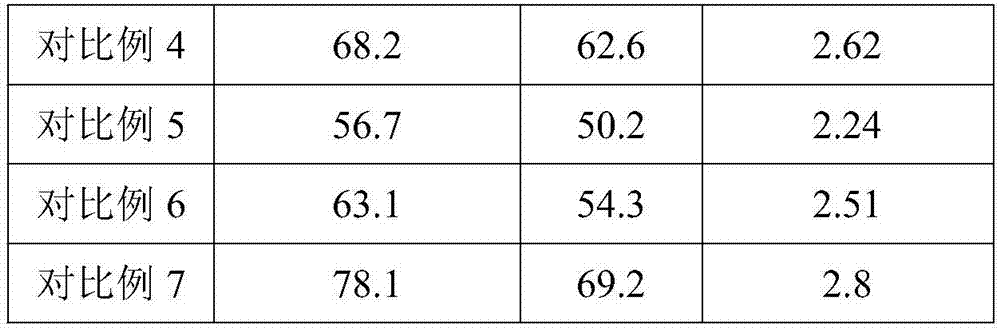

Examples

Embodiment 1

[0028] An application of modified calcium carbonate in plastics, the plastics, in parts by weight, include the following raw materials: 3 parts of modified calcium carbonate, 1 part of ethyl propionate, 4 parts of glass fiber, 40 parts of polycarbonate 0.5 part, 0.5 part of alunite, 0.5 part of crosslinking agent;

[0029] The modified calcium carbonate, in parts by weight, includes the following raw materials: 20 parts of calcium carbonate crushed matter, 5 parts of zinc stearate, 2 parts of chitosan, 0.1 part of surfactant, 0.03-0.05 part of solid acid, 0.08 part of coupling agent, 0.05 part of initiator, 0.03 part of sodium isooctyl succinate sulfonate, 0.05 part of sodium dodecylbenzene sulfonate, 0.01 part of trinonylphenyl phosphite, 0.01 part of tribasic lead sulfate , 0.01 part of sodium tripolyphosphate, and 0.07 part of a dispersant.

[0030] Wherein, the cross-linking agent includes the following raw materials in parts by weight: 0.2 part of dicumyl peroxide, 0.1 p...

Embodiment 2

[0043] An application of modified calcium carbonate in plastics, the plastics, in parts by weight, include the following raw materials: 5 parts of modified calcium carbonate, 3 parts of ethyl propionate, 6 parts of glass fiber, 50 parts of polycarbonate 1 part, 1 part of alum stone, 1 part of crosslinking agent;

[0044] The modified calcium carbonate, in parts by weight, comprises the following raw materials: 30 parts of calcium carbonate crushed matter, 10 parts of zinc stearate, 5 parts of chitosan, 0.3 part of surfactant, 0.05 part of solid acid, coupling 0.2 part of agent, 0.09 part of initiator, 0.05 part of sodium isooctyl succinate, 0.07 part of sodium dodecylbenzene sulfonate, 0.02 part of trinonylphenyl phosphite, 0.02 part of tribasic lead sulfate, three Sodium polyphosphate 0.02 part, dispersant 0.15 part.

[0045] Wherein, the crosslinking agent includes the following raw materials in parts by weight: 0.4 parts of dicumyl peroxide, 0.3 parts of pullulan, and 0.3 ...

Embodiment 3

[0058] An application of modified calcium carbonate in plastics, the plastics, in parts by weight, include the following raw materials: 4 parts of modified calcium carbonate, 2 parts of ethyl propionate, 5 parts of glass fiber, 45 parts of polycarbonate part, 0.8 part of alunite, 0.7 part of crosslinking agent;

[0059] The modified calcium carbonate, in parts by weight, comprises the following raw materials: 25 parts of calcium carbonate crushed matter, 7 parts of zinc stearate, 3 parts of chitosan, 0.2 part of surfactant, 0.04 part of solid acid, coupling 0.14 parts of agent, 0.07 parts of initiator, 0.04 parts of sodium isooctyl succinate, 0.06 parts of sodium dodecylbenzene sulfonate, 0.015 parts of trinonylphenyl phosphite, 0.015 parts of tribasic lead sulfate, three Sodium polyphosphate 0.016 part, dispersant 0.11 part.

[0060] Wherein, the cross-linking agent includes the following raw materials in parts by weight: 0.3 parts of dicumyl peroxide, 0.2 parts of pullulan,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com