Preparation method of Mg-RE-Ni alloy hydrogen storage material

A hydrogen storage material, mg-re-ni technology, applied in the field of preparation of Mg-RE-Ni alloy hydrogen storage materials, can solve the problems of difficult control of Mg composition, increase process cost, etc., achieve high sample activity, reduce equipment The effect of cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A preparation method of a Mg-RE-Ni alloy hydrogen storage material, comprising the following steps:

[0024] (1) Mix the Mg, RE and Ni powders according to the molar percentage of 60:10:30, put them into a stainless steel ball mill under an argon protective atmosphere, and grind them uniformly with a planetary ball mill to obtain a mixture. RE is rare earth metal Y.

[0025] (2) the mixture is loaded into the mould under the protection of argon, and pressed with a pressure of 30Mpa and maintained for 5min to obtain a metal sheet; the metal sheet is placed in a graphite crucible mold, and then the metal sheet is sealed with graphite powder. upper and lower sides, and compacted, sealed.

[0026] (3) placing the sealed mold in a tube furnace under an argon atmosphere for powder sintering to obtain a sintered alloy;

[0027] Powder sintering refers to gradient sintering in which the heating rate of 10K / min is first raised to between 640°C and the temperature ...

Embodiment 2

[0030] Embodiment 2 A preparation method of a Mg-RE-Ni alloy hydrogen storage material, comprising the following steps:

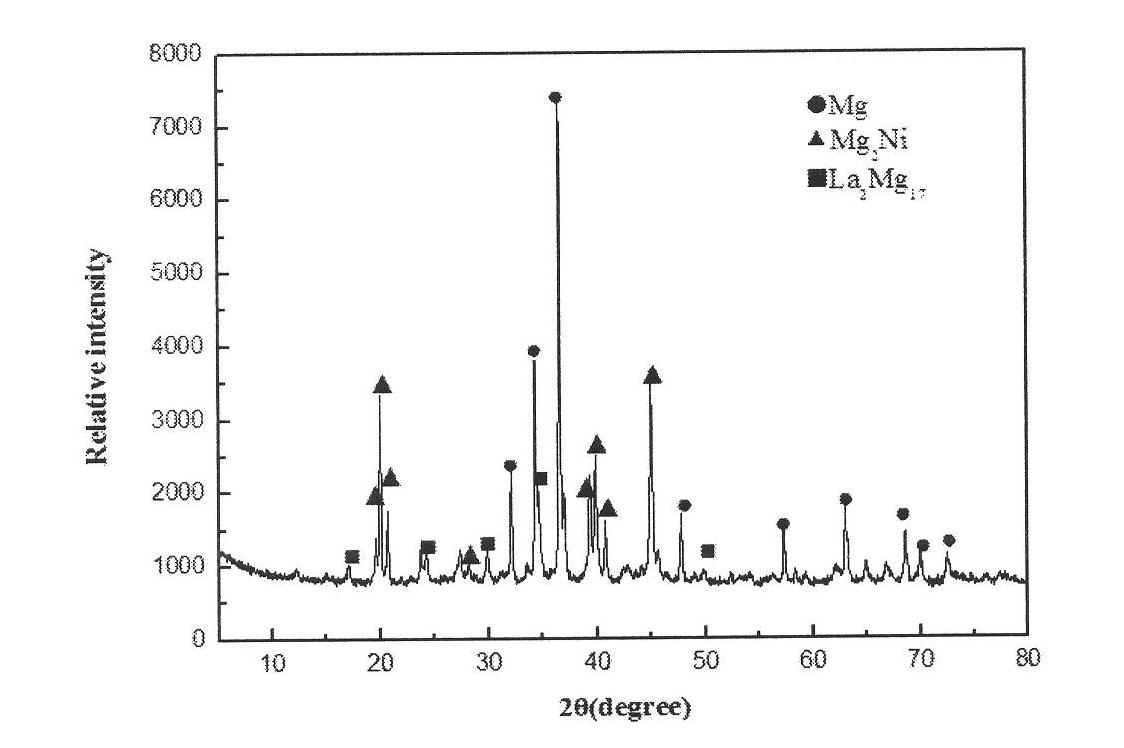

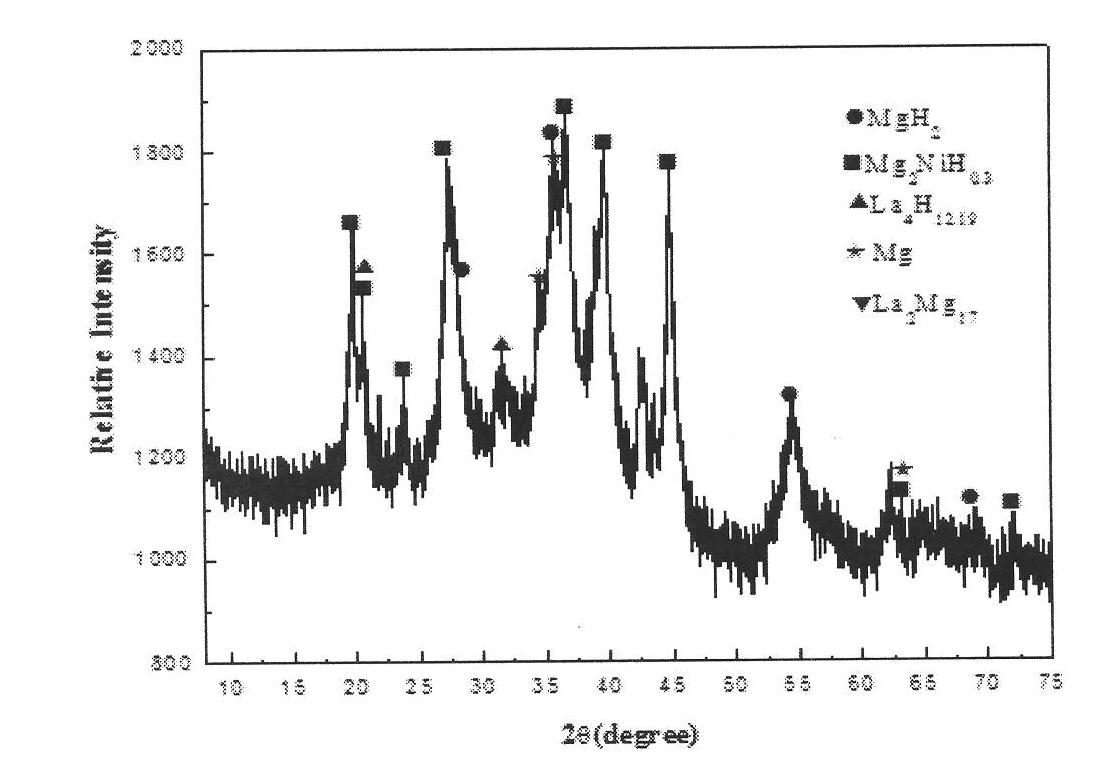

[0031] (1) Mix the Mg, RE and Ni powders according to the molar percentage of 72:8:20, put them into a stainless steel ball mill under an argon protective atmosphere, and grind them uniformly with a planetary ball mill to obtain a mixture. RE is the rare earth metal La.

[0032] (2) The mixture is loaded into the mould under argon protection, and pressed at a pressure of 20Mpa and maintained for 10min to obtain a metal sheet; the metal sheet is placed in a graphite crucible mold, and then the metal sheet is sealed with graphite powder. upper and lower sides, and compacted, sealed.

[0033] (3) placing the sealed mold in a tube furnace under an argon atmosphere for powder sintering to obtain a sintered alloy;

[0034] Powder sintering refers to gradient sintering in which the heating rate of 7K / min is first raised to between 700°C and the temperature is ke...

Embodiment 3

[0037] Embodiment 3 A preparation method of a Mg-RE-Ni alloy hydrogen storage material, comprising the following steps:

[0038] (1) Mix the Mg, RE and Ni powders according to the molar percentage of 72:8:20, put them into a stainless steel ball mill under an argon protective atmosphere, and grind them uniformly with a planetary ball mill to obtain a mixture. RE is the rare earth metal Ce.

[0039] (2) The mixture is loaded into the mould under argon protection, and pressed at a pressure of 20Mpa and maintained for 10min to obtain a metal sheet; the metal sheet is placed in a graphite crucible mold, and then the metal sheet is sealed with graphite powder. upper and lower sides, and compacted, sealed.

[0040] (3) placing the sealed mold in a tube furnace under an argon atmosphere for powder sintering to obtain a sintered alloy;

[0041] Powder sintering refers to gradient sintering in which the heating rate of 10K / min is first raised to between 800°C and the temperature is k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com