Honeycomb ceramic carrier and preparation method thereof

A honeycomb ceramic carrier and raw material technology, applied in ceramic products, other household utensils, applications, etc., can solve the problems of insufficient pore size, small pitch, and reduced reaction and diffusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take by weighing 45kg of talc, 20kg of alumina, 8kg of aluminum hydroxide, 15kg of silica powder, 8kg of kaolin, 5kg of methylcellulose as a surfactant, and 8kg of 325 mesh cornstarch as a pore-forming agent. Mix well in a mixer.

[0024] Weigh 2 kg of glycerin and 2 kg of soybean oil as a lubricant, add them together with 30 kg of deionized water into the above-mentioned mixed powder, and stir evenly to obtain the mud for honeycomb ceramic carrier.

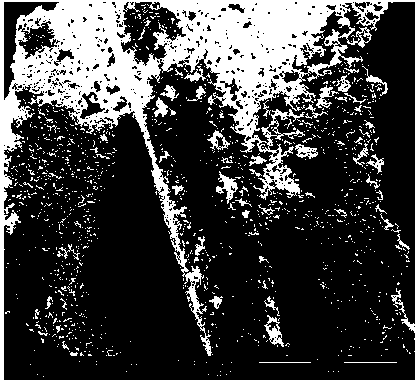

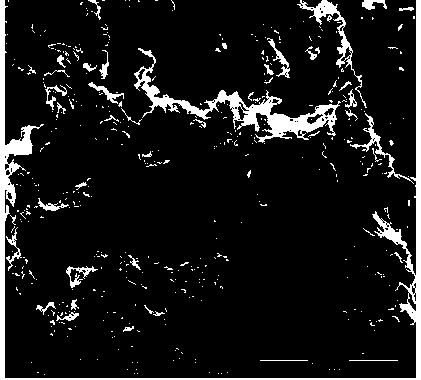

[0025] The mud was aged at 20°C for 24 hours, extruded into a honeycomb ceramic green body with a wall thickness of 0.6mm and 50 holes / square inch, and then calcined at 1400°C after microwave drying.

[0026] The obtained honeycomb ceramic carrier has a median pore size of 24 μm and a porosity of 56%.

Embodiment 2

[0028] Weigh 35kg talc, 25kg alumina, 10kg aluminum hydroxide, 20kg silica powder, 10kg kaolin, weigh 1kg polyethylene oxide, 2kg polyvinyl alcohol as surfactant, weigh 10kg 325 mesh graphite powder as pore-forming agent, mix various raw materials in a mixer evenly.

[0029] Weigh 2kg of glycerin and 3kg of tung oil as a lubricant, add them together with 28kg of deionized water into the above-mentioned mixed powder, and stir evenly to obtain the mud for honeycomb ceramic carrier.

[0030] The mud was aged at 20°C for 24 hours, extruded into a honeycomb ceramic green body with a wall thickness of 0.9 and 40 holes / square inch, dried by microwaves, and then calcined at 1410°C.

[0031] The obtained honeycomb ceramic carrier has a median pore diameter of 35 μm and a porosity of 65%.

Embodiment 3

[0033] Weigh 40kg talc, 20kg alumina, 15kg aluminum hydroxide, 15kg silica powder, 10kg kaolin, weigh 2kg polyethylene oxide, 2kg hydroxypropyl methylcellulose as surfactant, weigh 10kg 200 mesh starch As a pore-forming agent, mix various raw materials in a mixer evenly.

[0034] Weigh 2 kg of tung oil and 2 kg of palm oil as lubricants, add them together with 25 kg of deionized water into the above-mentioned mixed powder, and stir evenly to obtain mud for honeycomb ceramic carrier.

[0035] The mud was aged at 20°C for 24 hours, extruded into a honeycomb ceramic body with a wall thickness of 0.8 and 40 holes / square inch, dried by microwave, and calcined at 1420°C.

[0036] The porosity and pore size of the honeycomb carrier were measured by mercury porosimeter mercury intrusion method, and the median pore size of the honeycomb ceramic carrier was measured to be 40 μm, and the porosity was 63%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com