Method for applying coating on cordierite honeycomb ceramics and applications thereof

A technology of cordierite honeycomb and ceramics, which can be used in applications, ceramic products, and other household appliances, etc., and can solve problems such as the inability to modify aluminum sol, coating pollution, and concentration limitations of aluminum sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

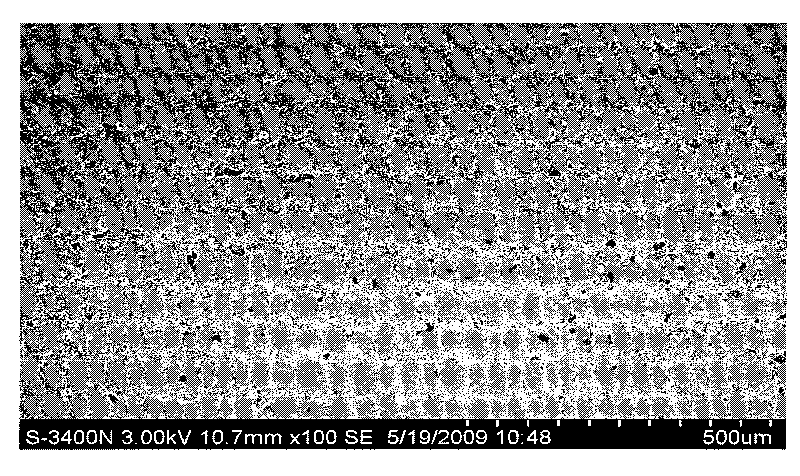

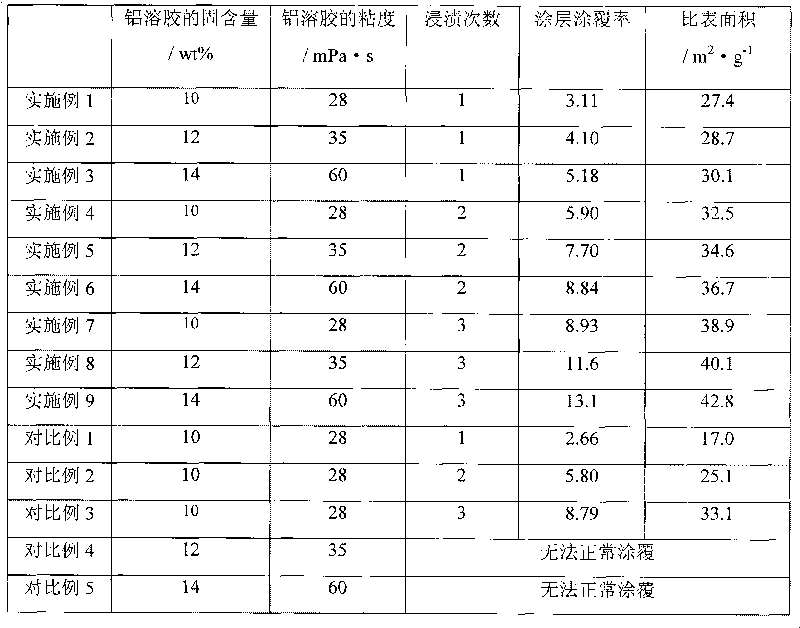

[0018] Pretreatment of cordierite honeycomb ceramics: heat and boil the cordierite honeycomb ceramics in 12wt% nitric acid solution for 20 minutes, take them out, rinse them with distilled water and dry them; cut the processed honeycomb ceramics into 15mm×15mm×25mm.

[0019] Using the pseudo-boehmite slurry with a solid content of 10wt% as raw material, add nitric acid, the acid-aluminum molar ratio is 0.1, stir and reflux in a water bath at 80°C for 4 hours, and age overnight; then the pretreated cordierite honeycomb ceramics One end is immersed in the aluminum sol impregnation solution, the other end is connected to the vacuum device through a rubber hose, and the vacuum degree is controlled to be 0.02MPa; then every 3 minutes, the vacuum device is suspended, and the reverse air is blown for 10 seconds, and then the vacuum is repeated for impregnation; finally, the vacuum is pumped After a total of 6 minutes of extraction and impregnation, turn off the vacuum device, take out...

Embodiment 2

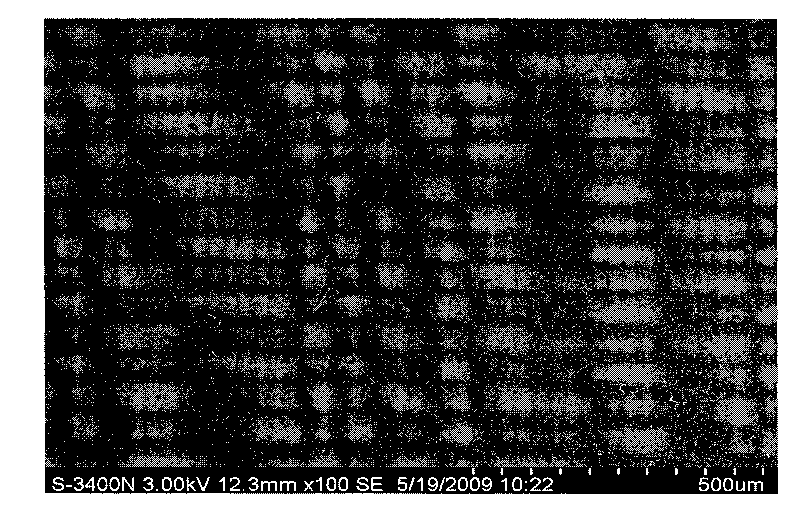

[0022] Using the pseudo-boehmite slurry with a solid content of 12wt% as raw material, add nitric acid, the acid-aluminum molar ratio is 0.1, stir and reflux in a water bath at 80°C for 6 hours, and age overnight; then the pretreated cordierite honeycomb ceramics One end is immersed in the aluminum sol impregnation solution, the other end is connected to the vacuum device through a rubber hose, and the vacuum degree is controlled to be 0.05MPa; then every 3 minutes, the vacuum device is suspended, the reverse air is blown for 20 seconds, and then the vacuum is repeated for impregnation; finally, the vacuum is pumped After extraction and impregnation for a total of 12 minutes, turn off the vacuum device, take out the honeycomb ceramics, blow off the residual liquid inside the channels, dry at 100°C for 3 hours, and bake at 500°C for 4 hours.

[0023] The aluminum sol used in this example has a solid content of 12 wt % and a viscosity of 35 mPa·s. The coating coverage and specifi...

Embodiment 3

[0025] Using the pseudo-boehmite slurry with a solid content of 14wt% as raw material, add nitric acid, the acid-aluminum molar ratio is 0.1, stir and reflux in a water bath at 80°C for 8 hours, and age overnight; then the pretreated cordierite honeycomb ceramics One end is immersed in the aluminum sol impregnation solution, the other end is connected to the vacuum device through a rubber hose, and the vacuum degree is controlled to be 0.07MPa; then every 3 minutes, the vacuum device is suspended, the reverse air is blown for 30 seconds, and then the vacuum is repeated for impregnation; finally, the vacuum is pumped After a total of 9 minutes of extraction and impregnation, turn off the vacuum device, take out the honeycomb ceramics, blow off the residual liquid inside the channels, dry at 110°C for 2 hours, and bake at 500°C for 4 hours.

[0026] The aluminum sol used in this example has a solid content of 14 wt % and a viscosity of 60 mPa·s. The coating coverage and specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com