Selective catalyst for removing oxynitrides from tail gases of diesel vehicles and preparation method thereof

A nitrogen oxide, selective technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. problem, to achieve the effect of good resistance to H2O and SO2 poisoning, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

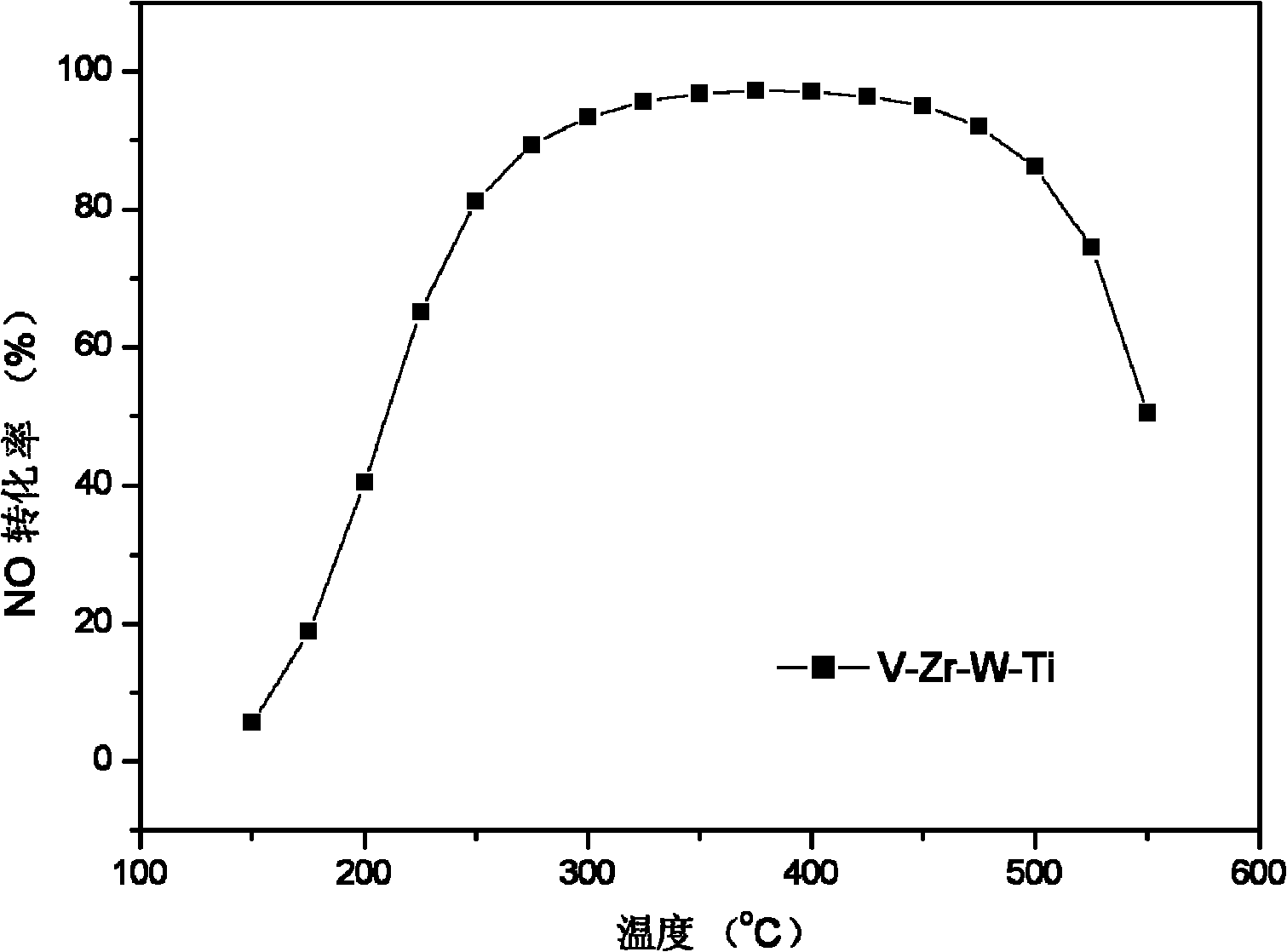

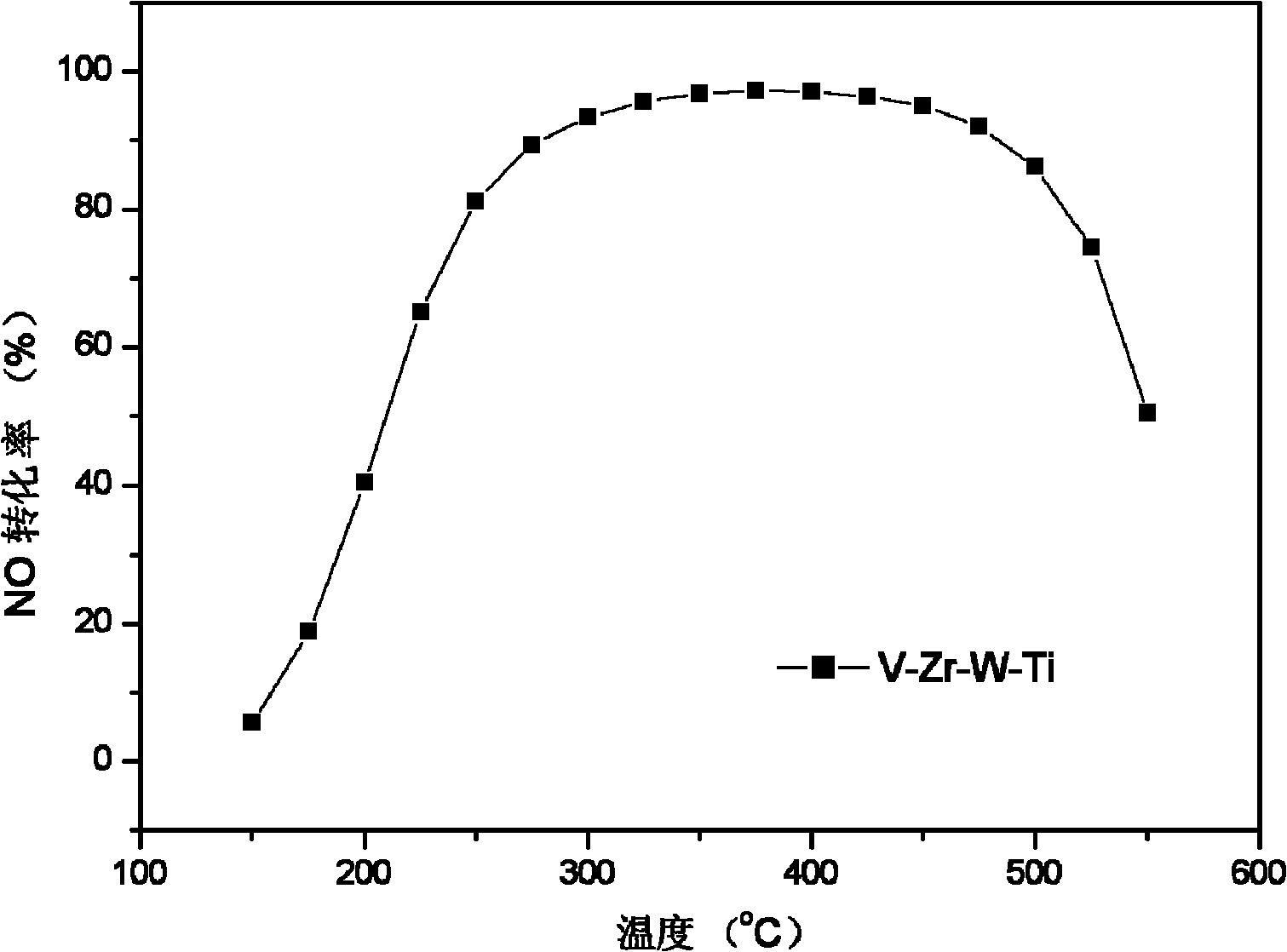

Image

Examples

Embodiment 1

[0027] Example 1 Weigh 3.33 g of oxalic acid and dissolve it in water, heat it at 80°C to completely dissolve, and prepare a 5% oxalic acid aqueous solution. Add 2g of vanadium pentoxide to the oxalic acid solution, and stir for 0.5h at a constant temperature of 70°C until it is completely dissolved. Then add 8.3 g of zirconyl nitrate to the above solution, and stir for 0.5 h at a constant temperature of 70°C until it is completely dissolved. Add 200ml of water to the system, continue to add 100g of tungsten titanium powder, that is, add 8-10g of tungsten trioxide and 90-92g of titanium dioxide, and stir at 70°C until it is completely dissolved. 20% of the mass of the mixed solution was added to polyacrylamide as a binder, and stirred at room temperature for 2 hours until completely dissolved to obtain a slurry. The blank cordierite honeycomb ceramic carrier was immersed in the slurry, and the residual liquid in the pores was blown out after removal, dried at 100°C for 1.5 hou...

Embodiment 2

[0029] Weigh 4.67 g of oxalic acid and dissolve it in water, heat it at 60°C to completely dissolve, and prepare an 8% oxalic acid aqueous solution. Add 4g of vanadium pentoxide to the oxalic acid solution, and stir for 0.5h at a constant temperature of 60°C until it is completely dissolved. Then add 6.7 g of zirconium oxychloride to the above solution, and stir for 0.5 h at a constant temperature of 60°C until it is completely dissolved. Add 200ml of water to the system, continue to add 100g of tungsten titanium powder, that is, add 8-10g of tungsten trioxide and 90-92g of titanium dioxide, and stir at a constant temperature of 60°C until completely dissolved. A silica sol with 5% of the mass of the mixed solution was added thereto as a binder, and stirred at room temperature for 2 hours until completely dissolved to obtain a slurry. The blank cordierite honeycomb ceramic carrier was immersed in the slurry, and the residual liquid in the pores was blown out after removal, dri...

Embodiment 3

[0031] Weigh 4.67 g of oxalic acid and dissolve it in water, heat it at 60°C to completely dissolve, and prepare an 8% oxalic acid aqueous solution. Add 6g of vanadium pentoxide to the oxalic acid solution, and stir for 0.5h at a constant temperature of 60°C until it is completely dissolved. Then add 11.7 g of zirconium acetate to the above solution, and stir it for 0.5 h at a constant temperature of 60°C until it is completely dissolved. Add 200ml of water to the system, continue to add 100g of tungsten titanium powder, that is, add 8-10g of tungsten trioxide and 90-92g of titanium dioxide, and stir at a constant temperature of 60°C until completely dissolved. 25% of the mass of the mixed solution is added to methylcellulose as a binder, and the mixture is stirred at room temperature for 2 hours to completely dissolve to obtain a slurry. The blank cordierite honeycomb ceramic carrier was immersed in the slurry, and after taking it out, the residual liquid in the pores was blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com