Method for removing carbon dioxide in natural gas by utilizing novel high specific surface active carbon material

A carbon dioxide, high specific surface technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, fuels, etc., can solve the problem of few applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

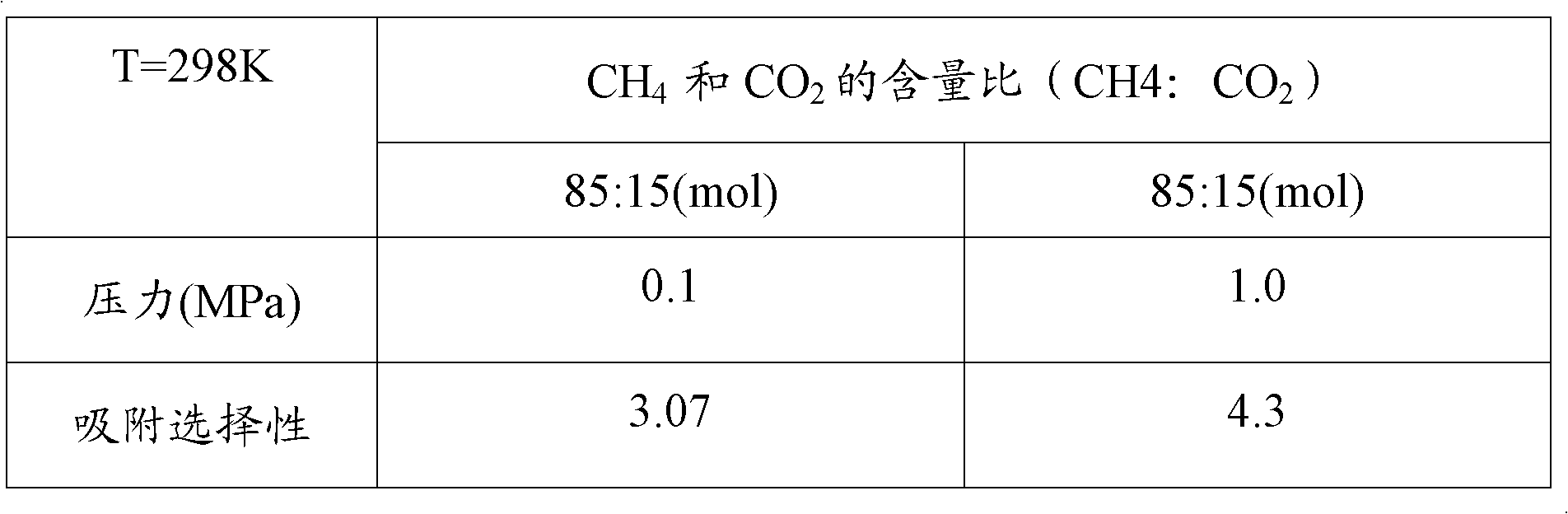

[0102] Example 1: The activated carbon material of the present invention is used to remove carbon dioxide in natural gas.

[0103] The implementation steps are as follows:

[0104] First, the cylindrical reactor to be used in this example was cleaned with an ultrasonic cleaner of the type SY1200T produced by Shanghai Ultrasonic Instrument Equipment Co., Ltd. for 3 times, 10 minutes each time, and dried after cleaning.

[0105] The activated carbon material is loaded into the cylindrical reactor. Close the reactor, let nitrogen gas pass through the reactor, clean the reactor and the pipelines connected to each equipment; use an infrared heater to heat the activated carbon material to a temperature of 550K, and perform impurity removal treatment; restart Shanghai Alphapa The diffusion vacuum pump produced by Vacuum Equipment Co., Ltd. with the trade name K.KT is vacuumed until 10 -2 Pa, close the vacuum pump, and then start the molecular pump produced by Beijing Taiyueheng V...

Embodiment 2

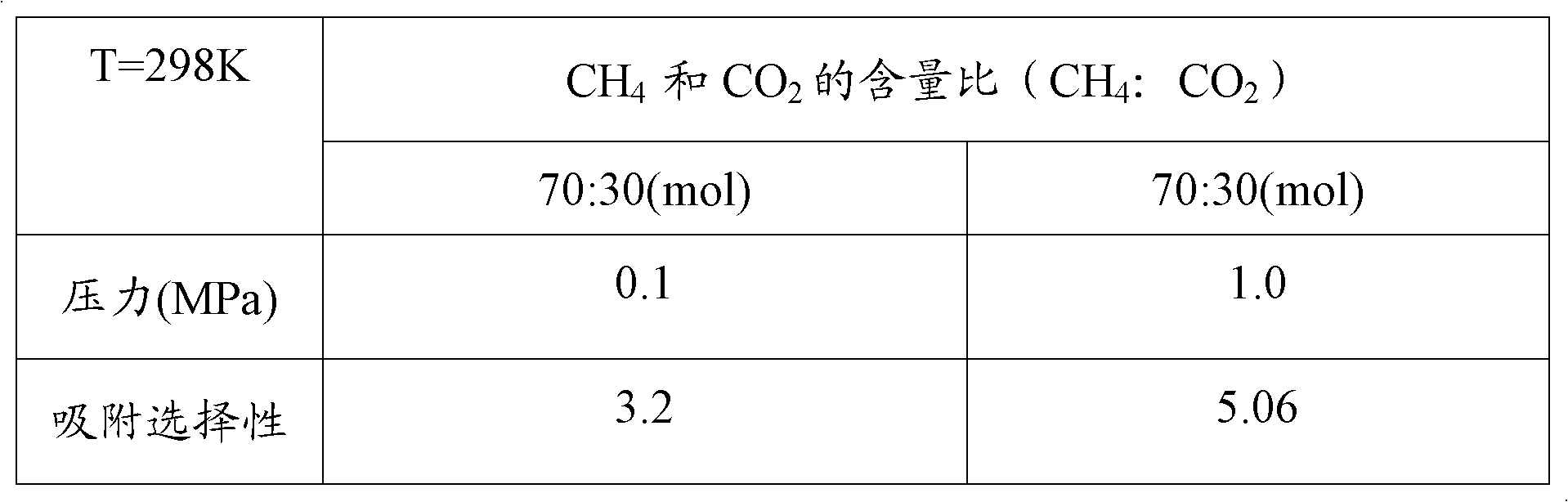

[0108] Example 2: The activated carbon material of the present invention is used to remove carbon dioxide in natural gas.

[0109] The implementation steps are as follows:

[0110] First, the cylindrical reactor to be used in this example was cleaned with an ultrasonic cleaner of the type SY1200T produced by Shanghai Ultrasonic Instrument Equipment Co., Ltd. for 3 times, 10 minutes each time, and dried after cleaning.

[0111] The activated carbon material is loaded into the cylindrical reactor. Close the reactor, let nitrogen gas pass through the reactor, clean the reactor and the pipelines connected to each equipment; use an infrared heater to heat the activated carbon microsphere adsorbent to a temperature of 520K, and perform impurity removal treatment; restart Shanghai The diffusion vacuum pump produced by Alphapa Vacuum Equipment Co., Ltd. with the trade name K.KT is vacuumed until 10 -2 Pa, close the vacuum pump, and then start the molecular pump produced by Beijing...

Embodiment 3

[0114] Example 3: The activated carbon material of the present invention is used to remove carbon dioxide in natural gas.

[0115] The implementation steps are as follows:

[0116] First, the cylindrical reactor to be used in this example was cleaned with an ultrasonic cleaner of the type SY1200T produced by Shanghai Ultrasonic Instrument Equipment Co., Ltd. for 3 times, 10 minutes each time, and dried after cleaning.

[0117] The activated carbon material is loaded into the cylindrical reactor. Close the reactor, let nitrogen gas pass through the reactor, clean the reactor and the pipelines connected to each equipment; use an infrared heater to heat the activated carbon microsphere adsorbent to a temperature of 500K, and perform impurity removal treatment; restart Shanghai The diffusion vacuum pump produced by Alphapa Vacuum Equipment Co., Ltd. with the trade name K.KT is vacuumed until 10 -2 Pa, close the vacuum pump, and then start the molecular pump produced by Beijing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com