Catalyst for producing furfuryl alcohol, preparation method thereof, and furfuryl alcohol production method

A catalyst, furfuryl alcohol technology, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the uncontrollable increase of catalyst preparation, unstable storage and use of silica sol, and no catalyst stability given and other problems, to achieve the effect of promoting high dispersion on the surface of the carrier, overcoming the infeasible barrier of carrier passivation treatment, and avoiding troubles during storage and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

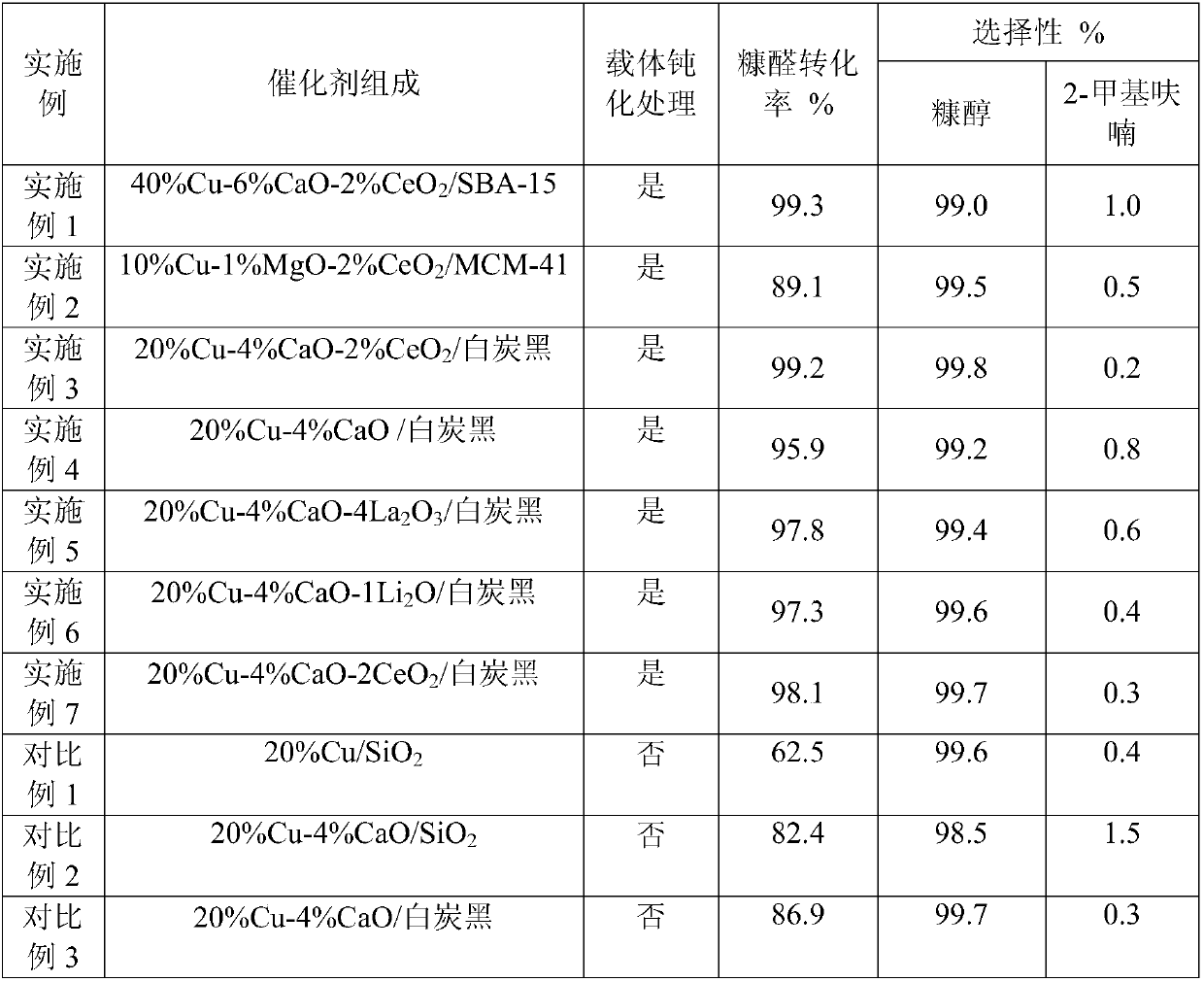

Examples

Embodiment 1

[0035] 40%Cu-6%CaO-2%CeO 2 Preparation and application of / SBA-15 catalyst

[0036] Put 10g of SBA-15 powder in 200ml of anhydrous toluene, add 2g of trimethylchlorosilane, reflux for 12h, filter to obtain a solid, and wash with ethanol aqueous solution until the filtrate is free of chlorine. The obtained solid was dried at 120° C. for 12 h. 14.62gCu(NO 3 ) 2 ·3H 2 O, 1.79g Ca(NO 3 ) 2 4H 2 O and 0.49gCe(NO 3 ) 2 ·6H 2 O was dissolved in 50ml of deionized water, and high-purity ammonia gas was pulsed into the above solution. After the pH of the system no longer increased, the ammonia gas was stopped, and the obtained solution system was stirred for 20 minutes. Weigh 5 g of the SBA-15 powder obtained from the above silanization treatment and add it into the solution, and stir at room temperature for 4 h. Transfer the uniformly stirred mixture system to a water bath at 80°C, continue stirring to remove the ammonia gas in the mixture, and remove the mixture from the wa...

Embodiment 2

[0039] 10%Cu-1%MgO-2%CeO 2 Preparation and Application of / MCM-41 Catalyst

[0040] Put 10g of MCM-41 powder in 200ml of anhydrous toluene, add 3g of aminopropyltriethoxysilane, reflux at 110°C for 12h, filter to obtain a solid, and wash the filtrate with aqueous ethanol until there is no chlorine. The obtained solid was dried at 120° C. for 12 h. 2.18g Cu(NO 3 ) 2 ·3H 2 O, 0.37g Mg(NO 3 ) 2 ·6H 2 O and 0.29g Ce(NO 3 ) 2 ·6H 2 O was dissolved in 50ml of deionized water, and high-purity ammonia gas was pulsed into the above solution. After the pH of the system no longer increased, the ammonia gas was stopped, and the obtained solution system was stirred for 20 minutes. Weigh 5g of passivation-treated MCM-41 powder and add it into the solution, and stir at room temperature for 4h. Transfer the uniformly stirred mixture system to a water bath at 80°C, continue stirring to remove the ammonia gas in the mixture, and remove the mixture from the water bath to cool down aft...

Embodiment 3

[0042] 20%Cu-4%CaO-2%CeO 2 / Preparation and application of white carbon black catalyst

[0043] 10 g of white carbon black was calcined at 750° C. for 1 hour in an air atmosphere to obtain passivated white carbon black. 5.14g Cu(NO 3 ) 2 ·3H 2 O, 0.84g Ca(NO 3 ) 2 4H 2 O and 0.34g Ce(NO 3 ) 2 ·6H 2 O was dissolved in 50ml of deionized water, and high-purity ammonia gas was pulsed into the above solution. After the pH of the system no longer increased, the ammonia gas was stopped, and the obtained solution system was stirred for 20 minutes. Weigh 5 g of passivated white carbon black and add it into the solution, and stir at room temperature for 4 h. Transfer the uniformly stirred mixture system to a water bath at 80°C, continue stirring to remove the ammonia gas in the mixture, and remove the mixture from the water bath to cool down after the pH of the system is reduced to nearly neutral. After the system was cooled to room temperature, filter cake was obtained by f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com