Organic waste anaerobic digestion-microbial electrolysis coupling reaction system and method thereof

A technology of microbial electrolysis and anaerobic digestion, applied in the field of anaerobic digestion-microbial electrolysis coupled reaction system, can solve the problems of low degradation rate of organic matter, poor methane production effect, poor system stability, etc., so as to reduce carbon dioxide content and reduce Effect of usage and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

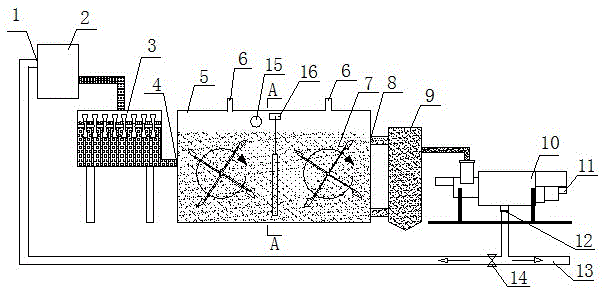

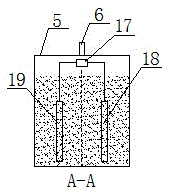

[0029] The present invention will be further described in conjunction with the accompanying drawings. Such as figure 1 As shown, the present invention includes a pretreatment device 2, a mixing device 3, an anaerobic digestion reactor 5, an extraction device 9 and a dehydration device 10, and the anaerobic digestion reactor is provided with a feed port 4 and a discharge port 8 and gas outlet 6, the extraction device is communicated with the anaerobic digestion reactor through the discharge port, the dehydration device is communicated with the extraction device, and the anaerobic digestion reactor is provided with a microbial electrolysis device 16 , the microbial electrolysis device includes an anode 19, a cathode 18 and a power supply 17, the anode is connected to the positive pole of the power supply, the cathode is connected to the negative pole of the power supply, and a cation exchange membrane 20 is arranged between the anode and the cathode of the microbial electrolysis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com