Medium-pressure recovery process of low steam/carbon ratio-three-section adsorption-evaporative ammonia-cooling carbamide production

An evaporative, water-to-carbon ratio technology, which is applied in the preparation of urea derivatives, organic compounds, chemical instruments and methods, etc., can solve the problems of high water-carbon molar ratio, slow reaction speed, and reduce energy consumption, and achieve carbon dioxide The effect of reducing content, increasing urea synthesis rate, reducing energy consumption and investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

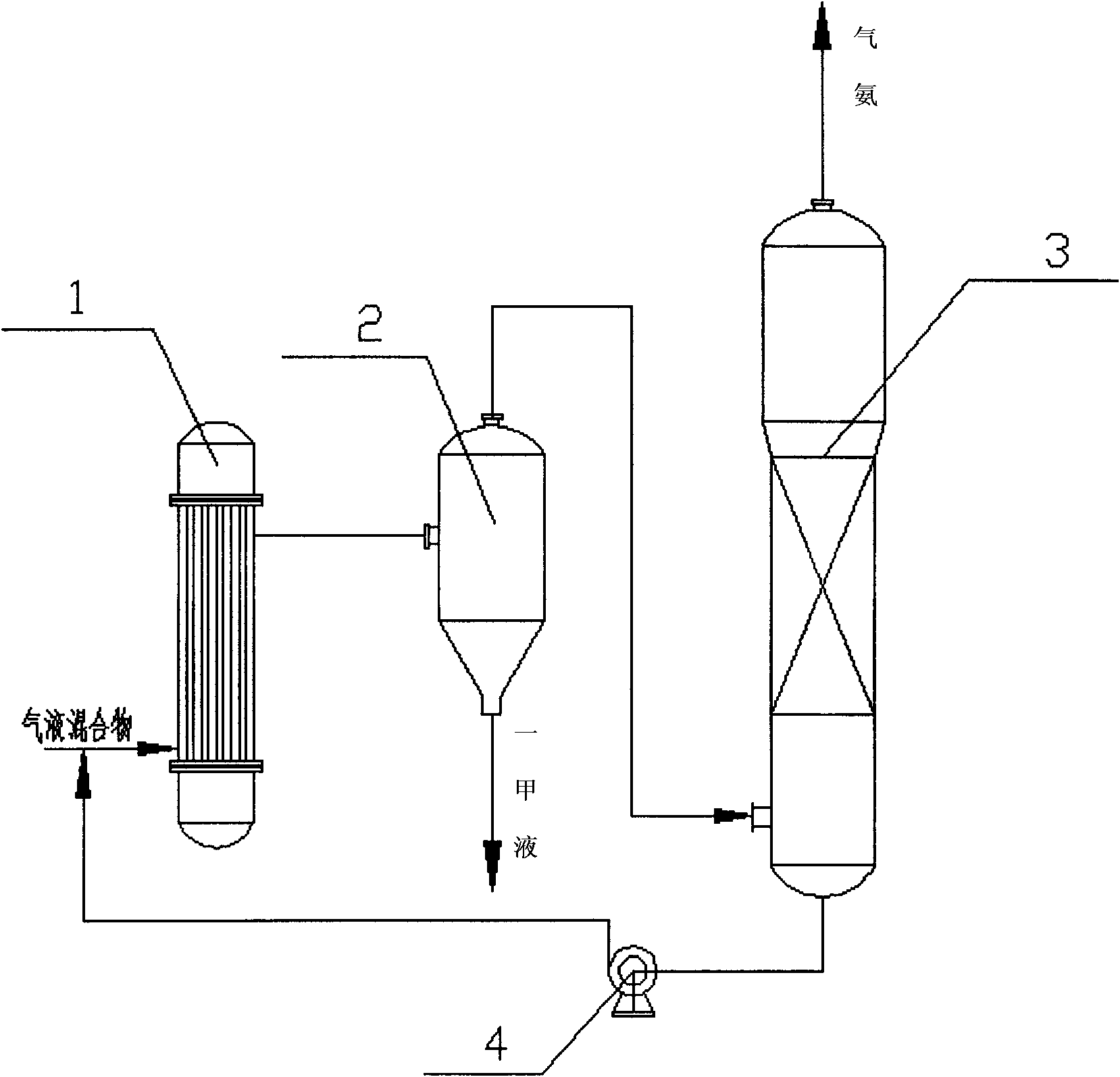

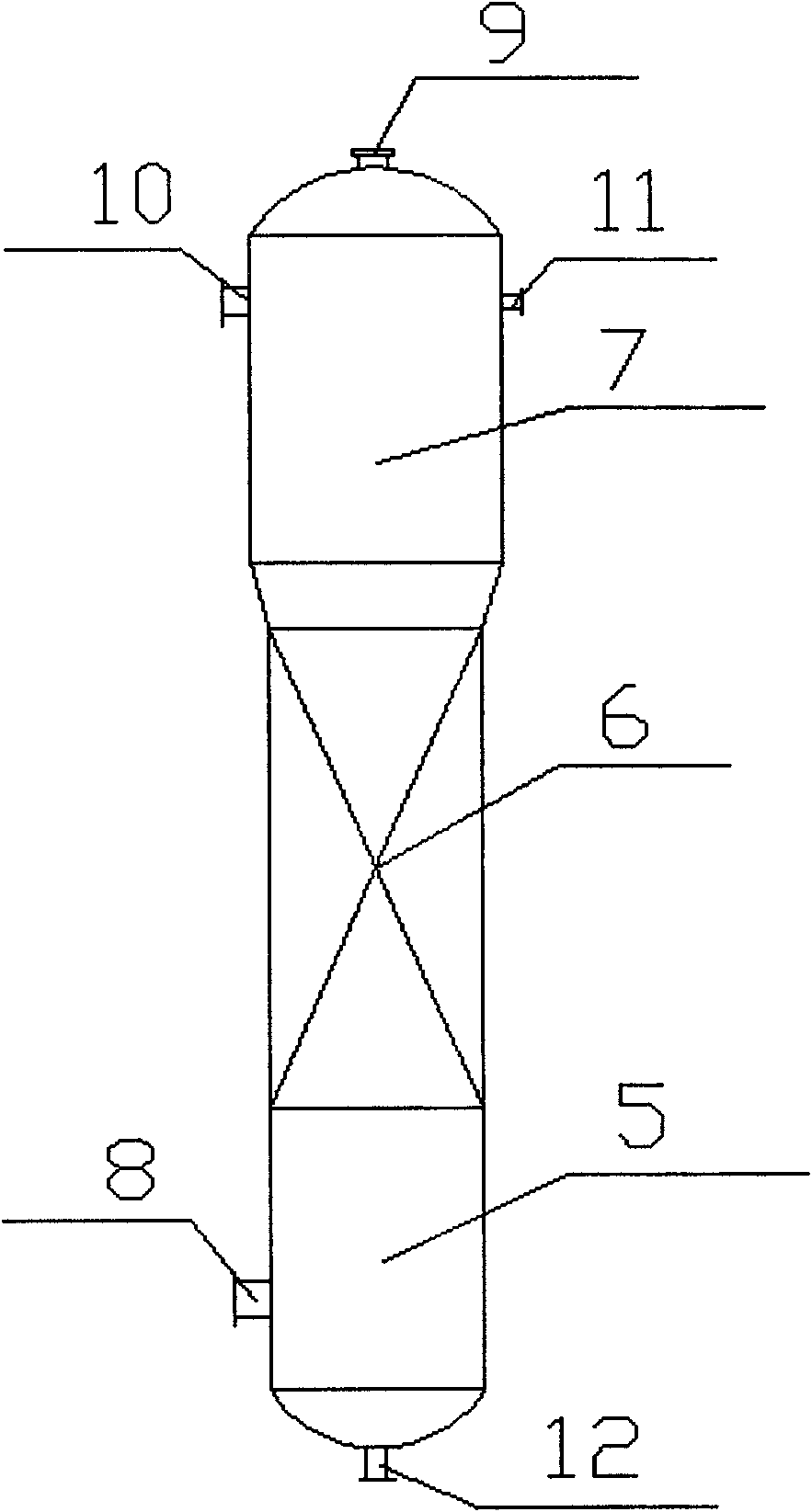

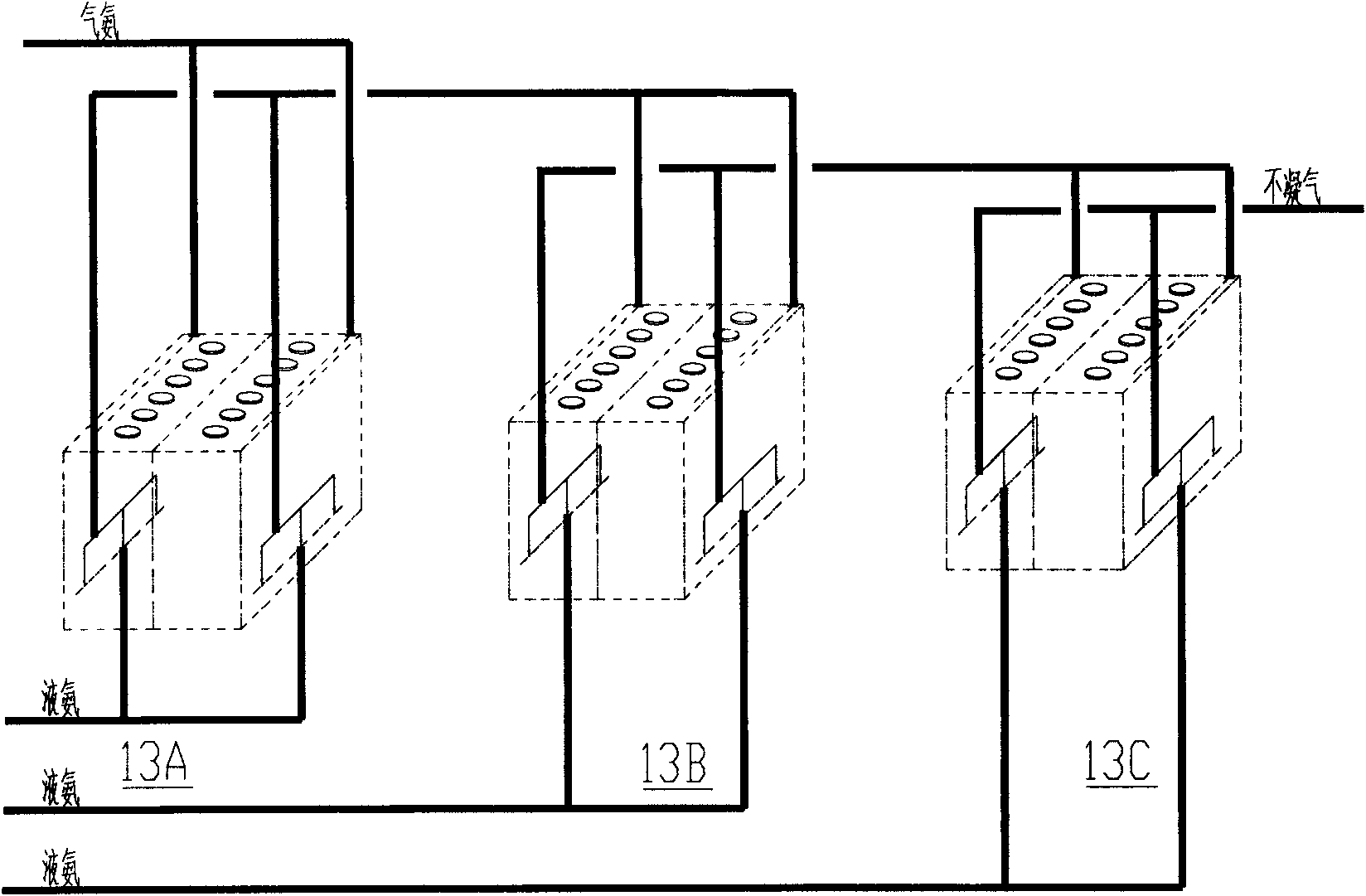

[0039] The main process equipment of the medium-pressure absorption process for urea production listed in this example includes a methylammonium condenser 1, a methylammonium separator 2, a medium-pressure absorption tower 3, a methylammonium booster pump 4, and an evaporative ammonia condenser 13. The medium-pressure absorption process of urea production of the present embodiment comprises the following steps:

[0040] (1), condensation absorption:

[0041]The gas phase separated by the medium-pressure decomposition heating system, which contains gaseous ammonia, carbon dioxide gas, and water vapor, enters the carbamate condenser 1, and the carbon dioxide gas and gaseous ammonia are absorbed at a temperature of 105°C and a pressure of 1.7MPa to form ammonium carbamate solution;

[0042] (2), separation:

[0043] The gas-liquid mixture that leaves the carbamate condenser 1 is separated in the carbamate separator 2, and the separated high-concentration ammonium carbamate solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com