Ti-Al intermetallic compound laminated composite material tube and preparation method thereof

A technology of intermetallic compounds and layered composite materials, applied in the field of Ti-Al intermetallic compound layered composite material tubes and its preparation, can solve the problems of difficult processing into tube shapes and difficult forming of Ti-Al layered composite materials , to achieve the effect of short manufacturing cycle, high forming precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

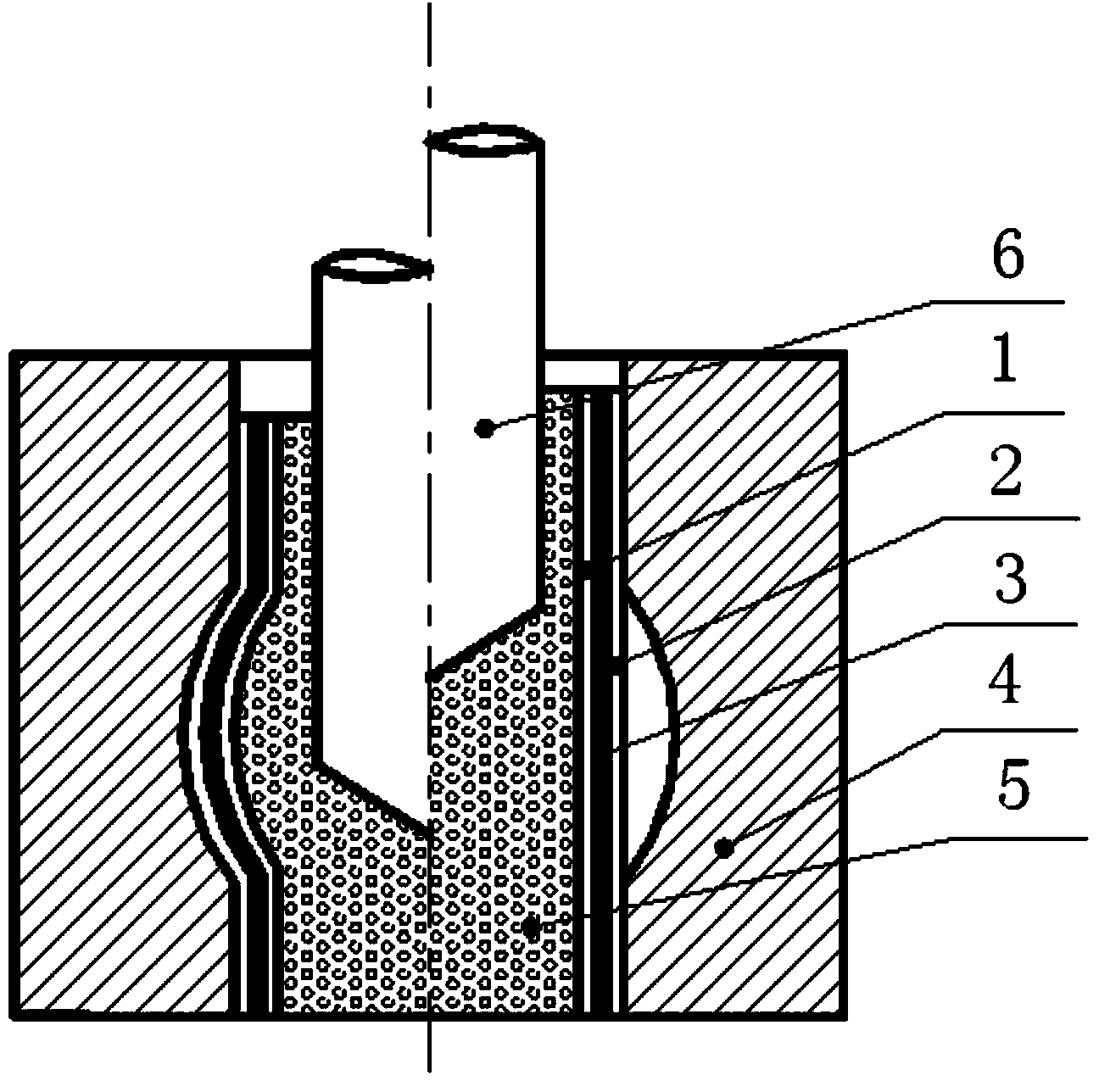

[0028] The present invention proposes a preparation method of a Ti-Al intermetallic compound layered composite material tube, such as figure 1 As shown, the preparation method of the Ti-Al intermetallic compound layered composite tube comprises:

[0029] Step A: Use titanium or titanium alloy pipes as the inner tube blank 1 and the outer tube blank 2, fill the middle of the inner tube blank 1 and the outer tube blank 2 with a metal interlayer 3, and the material of the intermediate layer is aluminum foil or aluminum powder, and the inner tube blank 1 and the two ends of the outer tube blank 2 are welded, so that the annular cavity between the inner tube blank and the outer tube blank is airtight, forming a sealed pocket, so that the inner tube blank 1 is hollow; the step A is, for example Occurs under normal temperature and pressure, which simplifies the processing conditions;

[0030] Step B: Then vacuumize the annular cavity between the inner tube blank and the outer tube b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com