Thermal molding method of high-strength aluminum alloy sheet

A technology of aluminum alloy sheet and thermoforming, which is applied in the field of forming of aluminum alloy sheet components, can solve the problems of restricting wide application, complex process path, high equipment cost, etc., achieve high forming quality, increase drawing limit, and enhance bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

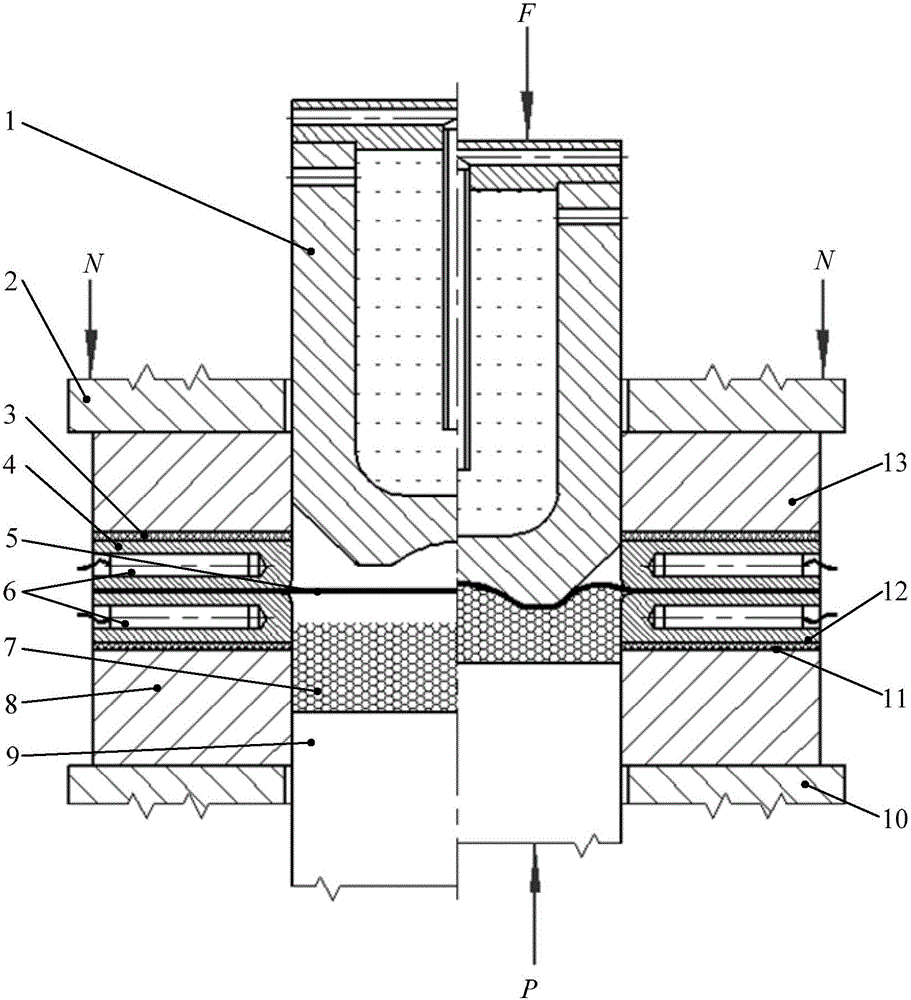

Embodiment 1

[0023] The back pressure head 9 moves to the set position, and the lower barrel 8 is filled with the heat-insulating granular medium 7, which is prepared from asbestos powder and expanded perlite products in a volume ratio of 1:1, and the average diameter of the granular body is It is 0.2mm to 0.4mm, has good fluidity, thermal conductivity is not more than 0.15W / (m·K), can maintain stable strength and hardness in the range of 0°C to 700°C, and has stable mechanical and chemical properties. In the heating furnace, heat the AA7075 aluminum alloy plate 5 to 480°C and keep it warm for 30 minutes; the upper and lower pressure edge rings 4 and 12 of the mold are heated to 480°C with the resistance heating device 6 provided, and the closed-loop temperature control system is used to keep the temperature constant. The edge ring is separated from other parts of the mold by the upper and lower heat insulation boards 3 and 11; the heated high-temperature plate is quickly moved to the heate...

Embodiment 2

[0025] The back pressure head 9 moves to the set position, and the lower barrel 8 is filled with the heat-insulating granular medium 7, which is prepared from asbestos powder and expanded perlite products in a volume ratio of 1:1, and the average diameter of the granular body is It is 0.2mm to 0.4mm, has good fluidity, thermal conductivity is not more than 0.15W / (m·K), can maintain stable strength and hardness in the range of 0°C to 700°C, and has stable mechanical and chemical properties. In the heating furnace, heat the AA6061 aluminum alloy plate 5 to 560°C and keep it warm for 30 minutes; the upper and lower pressure rings 4 and 12 of the mold are heated to 560°C with the resistance heating device 6 provided, and the closed-loop temperature control system is used to keep the temperature constant. The edge ring is separated from other parts of the mold by the upper and lower heat insulation boards 3 and 11; the heated high-temperature plate is quickly moved to the heated upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com