Aircraft gate area step-like wrap angle part drawing and forming method

A ladder-shaped, aircraft door technology, applied in the fields of thin material, sheet metal parts forming, and deep drawing of stainless steel plate parts, can solve the problems of thinning and cracking of edging, wrinkling of flange outer edge, etc. The effect of extreme, stable product quality and strong structural versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

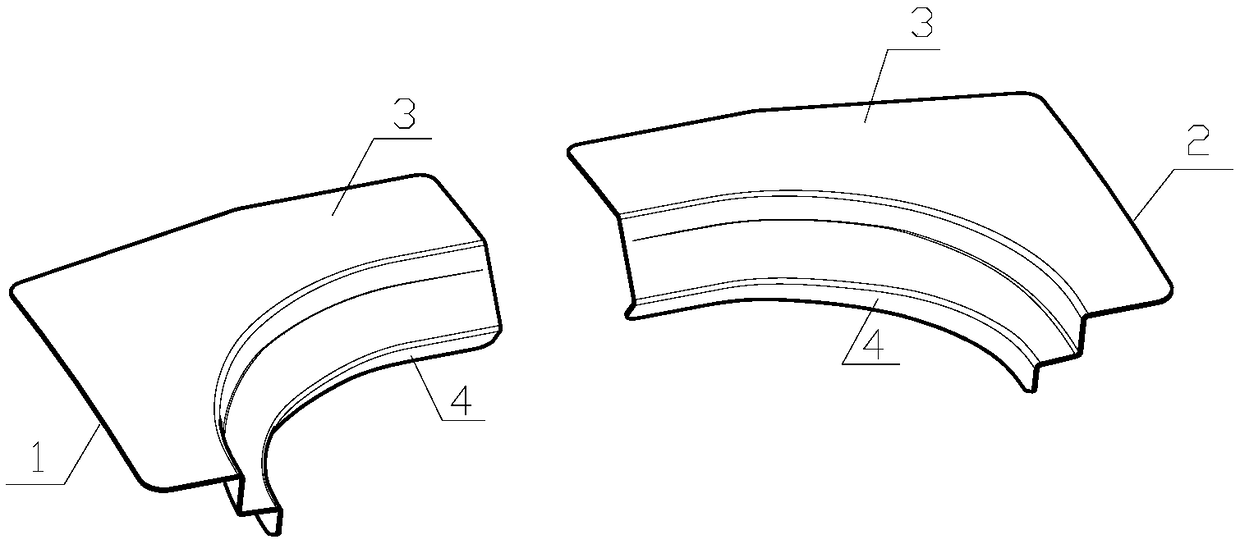

[0030] Referring to the accompanying drawings, the aircraft corner parts provided by the embodiment are as figure 1 As shown, this type of part is a large flange, stepped shape, variable curvature and complex door body with left corner part 1 and right corner part 2. The parts are simply divided into outer flange 3 and multi-bending side according to their appearance characteristics. wall 4. The biggest problem is that the outer edge flange 3 is seriously wrinkled and the lower part of the side wall 4 is thinned and cracked by using the existing technology to form integral parts, which cannot meet the requirements of the parts.

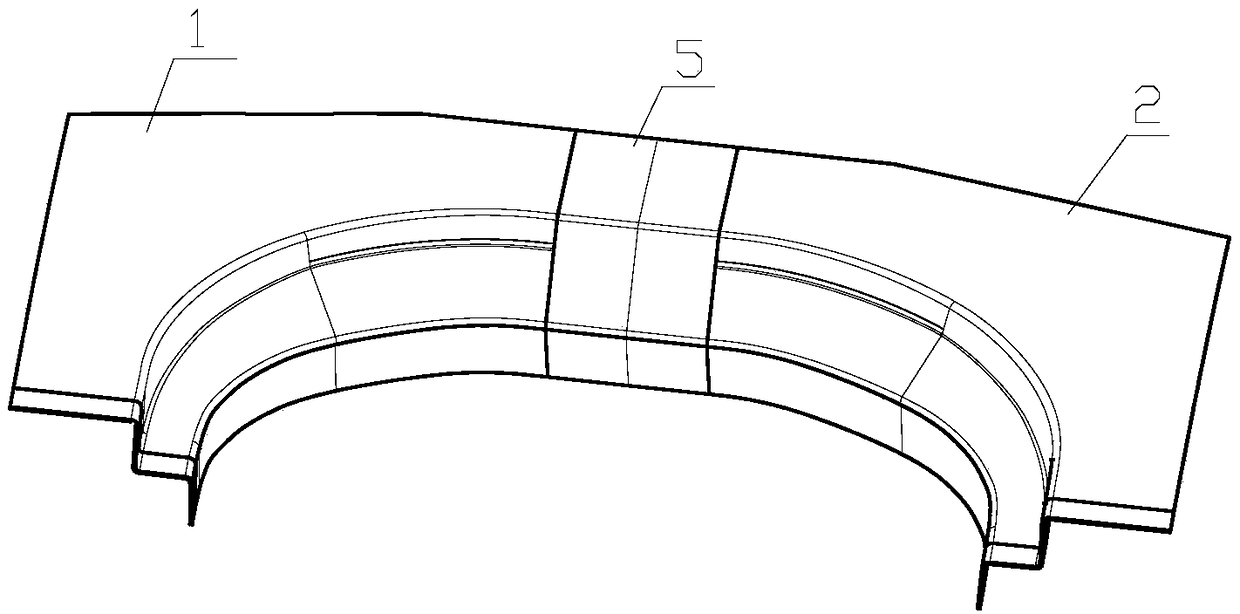

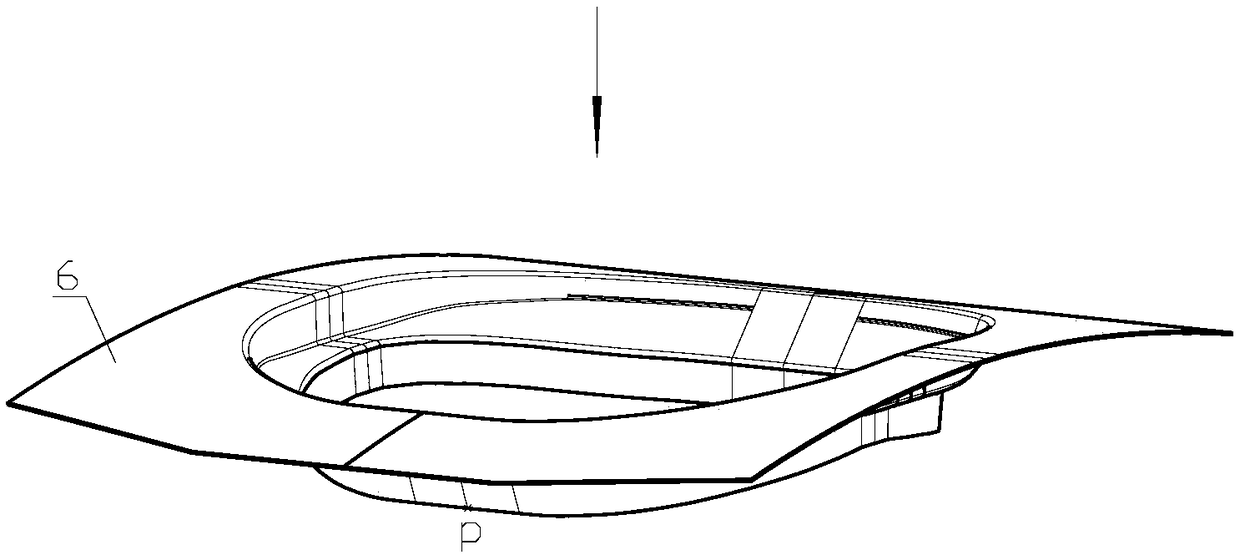

[0031] Such as Figure 2-8 As shown, a novel method for deep-drawing and forming of ladder-shaped corner-wrapped parts in the aircraft door area includes the following steps:

[0032] Step 1: Construct a process piece

[0033] The application constructs a process piece 10 such as Figure 2-4 shown. A group of left corner-wrapping pieces 1 and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com