Three-dimensional ultrasonic vibration assisted deep drawing processing device for miniature metal thin-walled cups

A metal thin, ultrasonic technology, applied in metal processing equipment, forming tools, fluids using vibration, etc., can solve the problems of complex structure and low production efficiency, and achieve the improvement of the drawing limit, the reduction of friction, and the reduction of friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

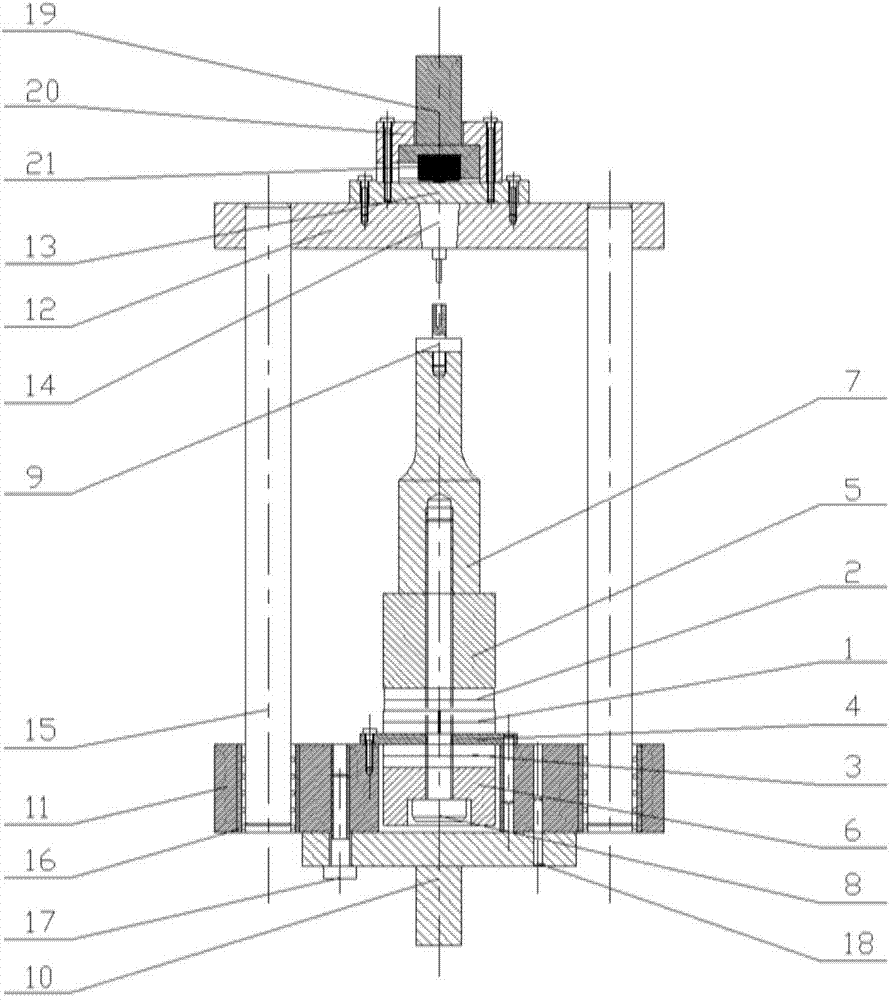

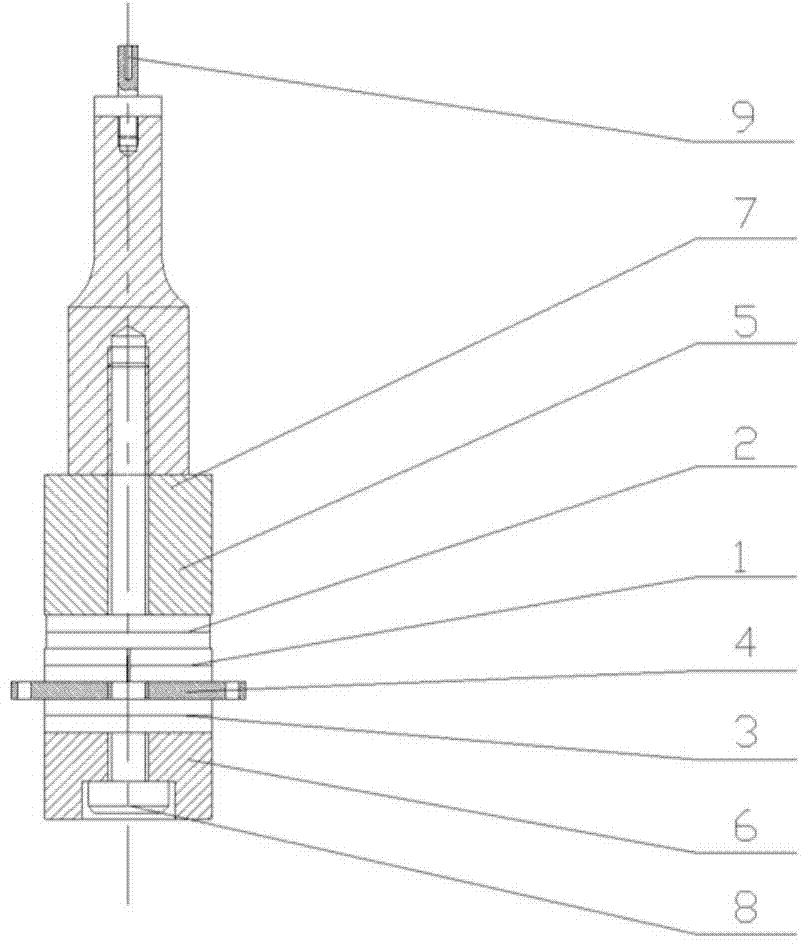

[0019] like figure 1 As shown, the present embodiment includes: guide post 15, guide sleeve 16, lower mold handle 10, lower template 11, bolt 17, pin 18, upper mold mechanism and vibration generating device. The upper mold mechanism includes: a punch 14 , an upper template 12 , an upper mold handle 19 , a mold handle fixing plate 20 , a force sensor 21 and a sensor fixing plate 13 . The upper die mechanism is connected with the press through the upper die handle 19, and in this embodiment, the upper die mechanism moves along the guide post 15 in the vertical direction to realize the drawing action. The punch 14 is embedded in the upper template 12 . The upper template 12, the sensor fixing plate 13, and the mold handle fixing plate 20 are connected successively from bottom to top. Force sensor 21 is placed in the groove in the big head of upper die handle 19, and the big part of upper die handle 19 is blocked by die handle fixed plate 20, thereby makes force sensor 21 lower ...

Embodiment 2

[0025] Utilize the three-dimensional ultrasonic vibration assisted drawing processing device of the miniature metal thin-walled cup described in embodiment 1 to carry out the processing of miniature metal parts, adopt the following steps:

[0026] 1) Fix the upper mold handle 19 and the lower mold handle 10 on the upper and lower clamps of the press respectively, and move the upper clamp of the press down so that the lower end of the guide post 15 penetrates into the guide sleeve 16.

[0027] 2) Place the blank on the die 9, move down the clamp on the press, and stop the press when the punch 14 just touches the blank.

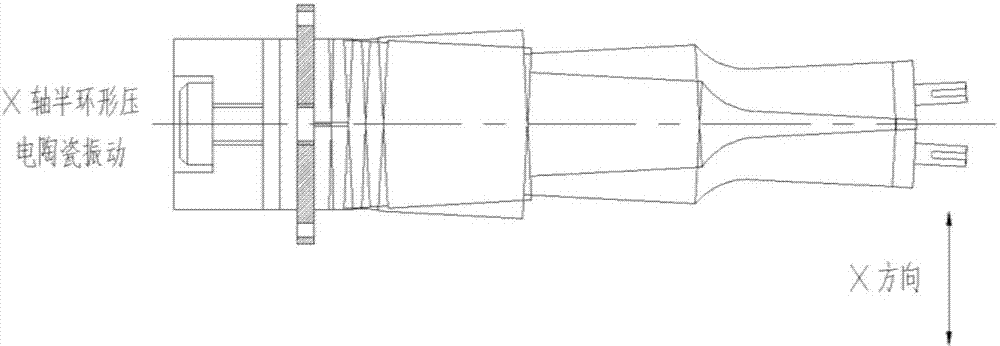

[0028] 3) Turn on the signal power of the X-axis semi-annular piezoelectric ceramic 1, the Y-axis semi-annular piezoelectric ceramic 2 and the Z-axis annular piezoelectric ceramic 3 respectively, so that they vibrate at the working frequency. And after being amplified by the horn 7, the three-dimensional amplitude is transmitted to the die 9.

[0029] 4) Start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com