Shaft sealing device for high-temperature pressure-proof star-type feeder

A shaft sealing and feeder technology, which is applied in the directions of engine sealing, combustion type, mechanical equipment, etc., can solve the problems of short service life of the shaft end sealing device, insufficient high temperature resistance and pressure resistance performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

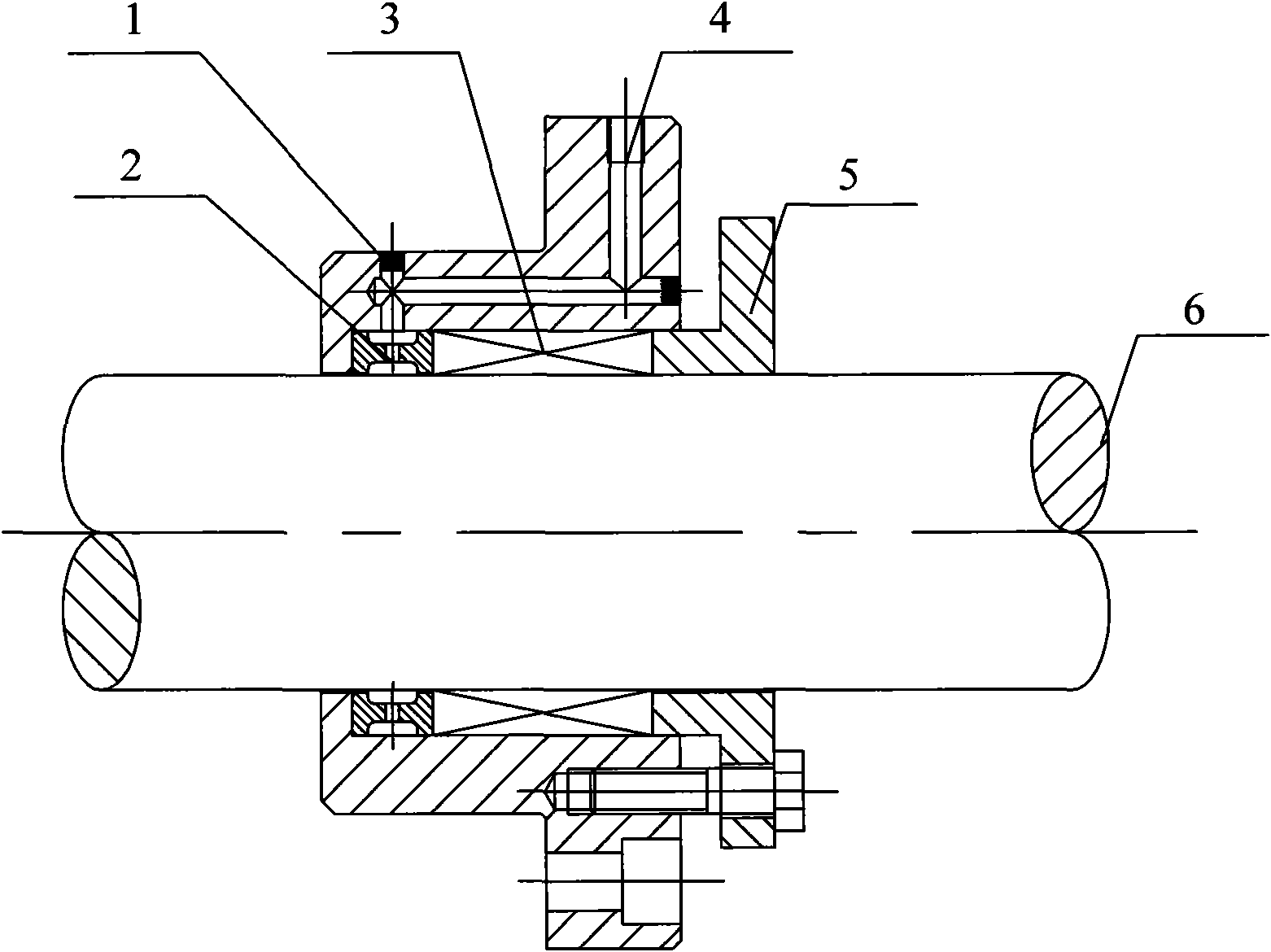

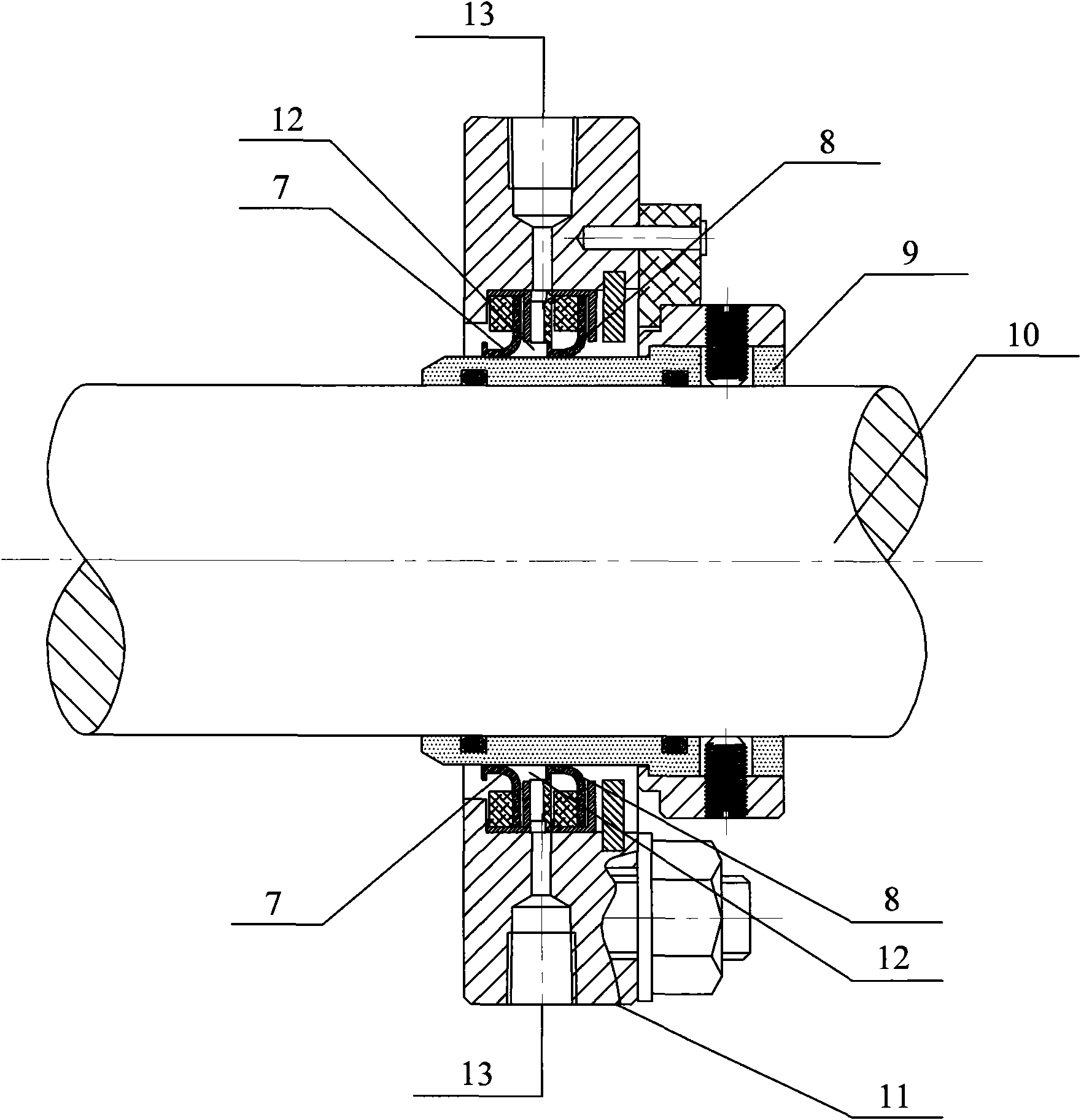

[0013] combine figure 1 It is a structural schematic diagram of the high-temperature and pressure-resistant star feeder shaft sealing device of the present invention, the rotating shaft 10 is the main transmission shaft, and the high-wear-resistant shaft sleeve 9 is installed on it, and the high-wear-resistant shaft sleeve 9 is made of high-wear-resistant alloy material Manufactured, for example, it can be silicon carbide composite SS316L, the shaft 10 and the shaft sleeve 9 are sealed by an O-ring, and there are two seals on the shaft sleeve 9: the first lip seal 7 and the second lip seal 8, which are connected to the shaft The seal of the sleeve 9 is a dynamic seal, and two air-tight holes 13 are provided between the first lip seal 7 and the second lip seal 8 .

[0014] In the pneumatic slag conveying system, the inlet of the feeder using this device is installed at the outlet of the conveying tank, and the conveying pipeline is installed under the outlet. The actual temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com