Laser scanning method for selective laser firing

A technology of laser sintering and laser scanning, which is applied in the field of laser scanning, can solve the problems of not proposing a better solution, increasing the cost of equipment and process, and increasing the difficulty of the system, so as to reduce the number of filling scans, improve the accuracy, and improve the scanning efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

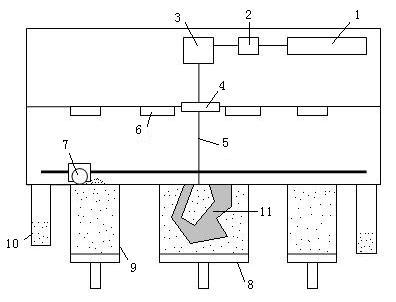

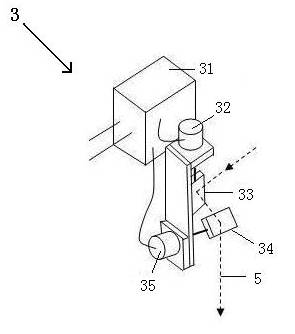

[0028] The equipment that the inventive method adopts is as figure 1As shown, in the SLS equipment, the powder feeding device 9 sends a certain amount of powder to the worktable, and after the powder is preheated, the powder spreading roller 7 evenly spreads the powder on the upper surface of the molded part 11 in the working cylinder 8 , the excess powder is recovered to the overflow powder cylinder 10, the heating device 6 heats the laid powder to a temperature just below the sintering point of the powder, the laser beam 5 emitted from the laser 1 is reflected by the prism 2 to the vibrating mirror system 3, and vibrates The mirror system 3 controls the laser beam 5 to pass through the laser window 4 to the working table for filling and scanning sintering of the cross-section powder of the workpiece 11 . The laser galvanometer system in SLS equipment 3 such as figure 2 As shown, two vibrating mirrors are included: x-axis vibrating mirror 33 and y-axis vibrating mirror 34, ...

Embodiment 2

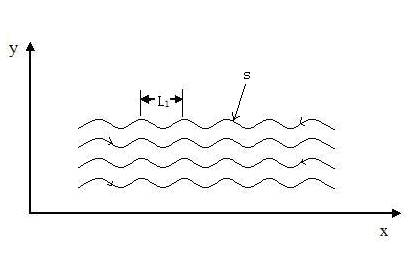

[0030] In this embodiment, the filling scanning path s of the laser beam is a spiral regular curve, and during a single scanning process of the spiral filling scanning, both the x-axis vibrating mirror and the y-axis vibrating mirror need to alternately swing in positive and negative directions. like Figure 4 As shown, the laser beam fills, scans and sinters the cross-section of the workpiece from the starting position according to the spiral scanning path, the galvanometer system controls the position of the laser beam, the scanning line waveform changes periodically, and the pitch L 2 1mm~5mm. For the first time, the overall scanning line grows spirally along the +x direction. When scanning to point a of the spiral coil, the growth direction of the scanning line changes to the -x direction, and when scanning to the point b of the spiral coil, the growth direction of the scanning line on the x-axis changes to +x direction, several changes in the x-axis direction will occur ...

Embodiment 1、2

[0031] In addition to Embodiments 1 and 2, the method of the present invention can also control the filling scanning path of the laser beam to be a curve of any shape as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com