Blank preparation method for rubber bladder formed thin-walled part

A thin-walled parts, rubber bag technology, applied in special data processing applications, instruments, electrical digital data processing and other directions, can solve the problems of insufficient accuracy, much manual experience, affecting production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

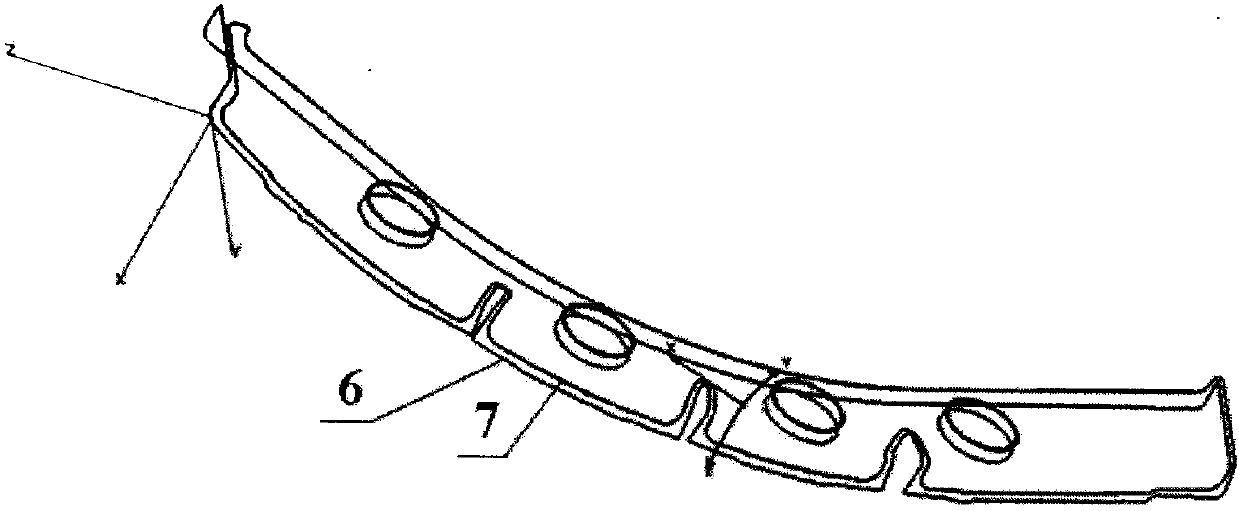

[0029] Such as figure 1 Shown, a kind of blank preparation method of rubber bag forming thin-walled parts, comprises the following steps:

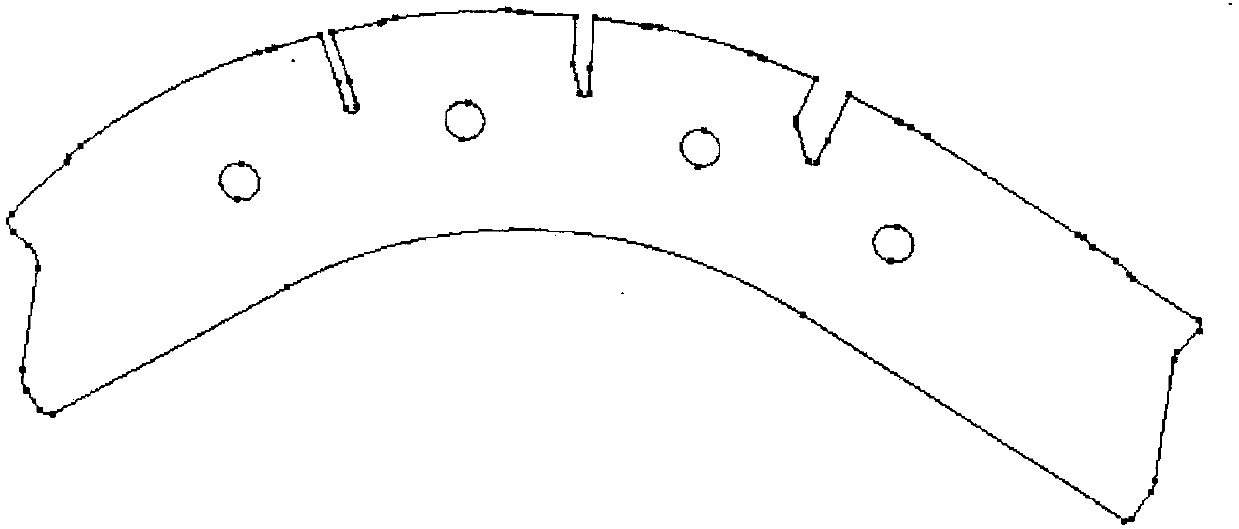

[0030] 1) In the CAD software CATIA V5, design a piece of wool according to the digital model of the part and the mold, such as figure 2 As shown, try to ensure that the wool is larger than the area of the part;

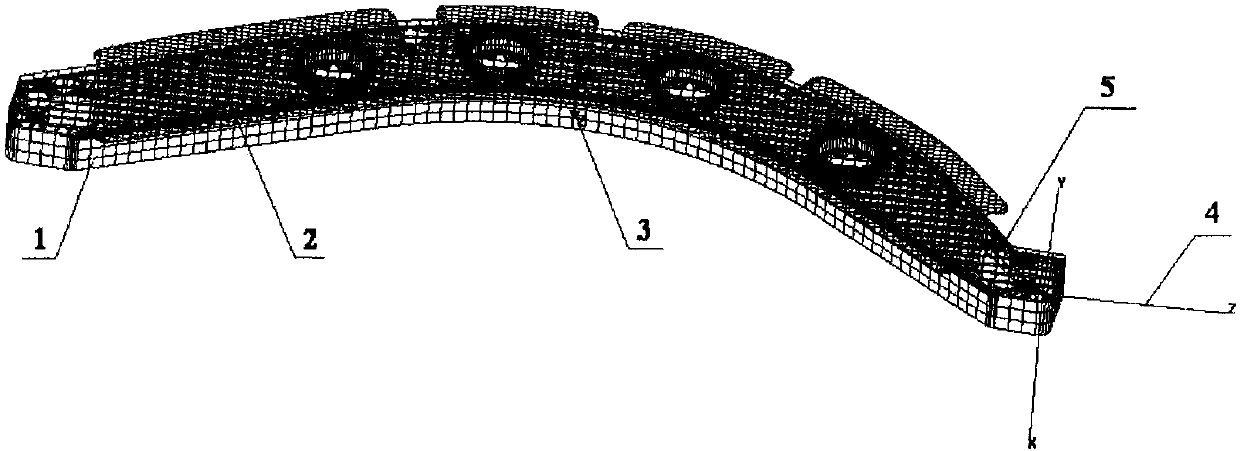

[0031] 2) In the CAE software PAMSTAMP2G, the precise forming simulation analysis of the rubber bag process is carried out on the wool, and the numerical model assembly relationship is as follows: image 3 shown;

[0032] 2.1) Create a new task in the pre-processing module, import the mold and wool IGS files, and perform grid division, using adaptive grid, the mold grid is 3mm, and the sheet grid is 2mm;

[0033] 2.2) Establish the system forming coordinate system 3, the positive direction of the Z axis is the forming direction of the rubber bag, and the global coordinate system is not used as a reference;

[0034] 2.3) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com