Probe card assembly

a technology of probe card and assembly, which is applied in the field of probe cards, can solve the problems of complex and costly, high cost, and high cost of vertical probe cards, and achieve the effects of avoiding permanent deformation of probes, reducing electrical interference or high-frequency cross talk, and low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Please refer to the drawings attached, the present invention will be described by means of an embodiment below.

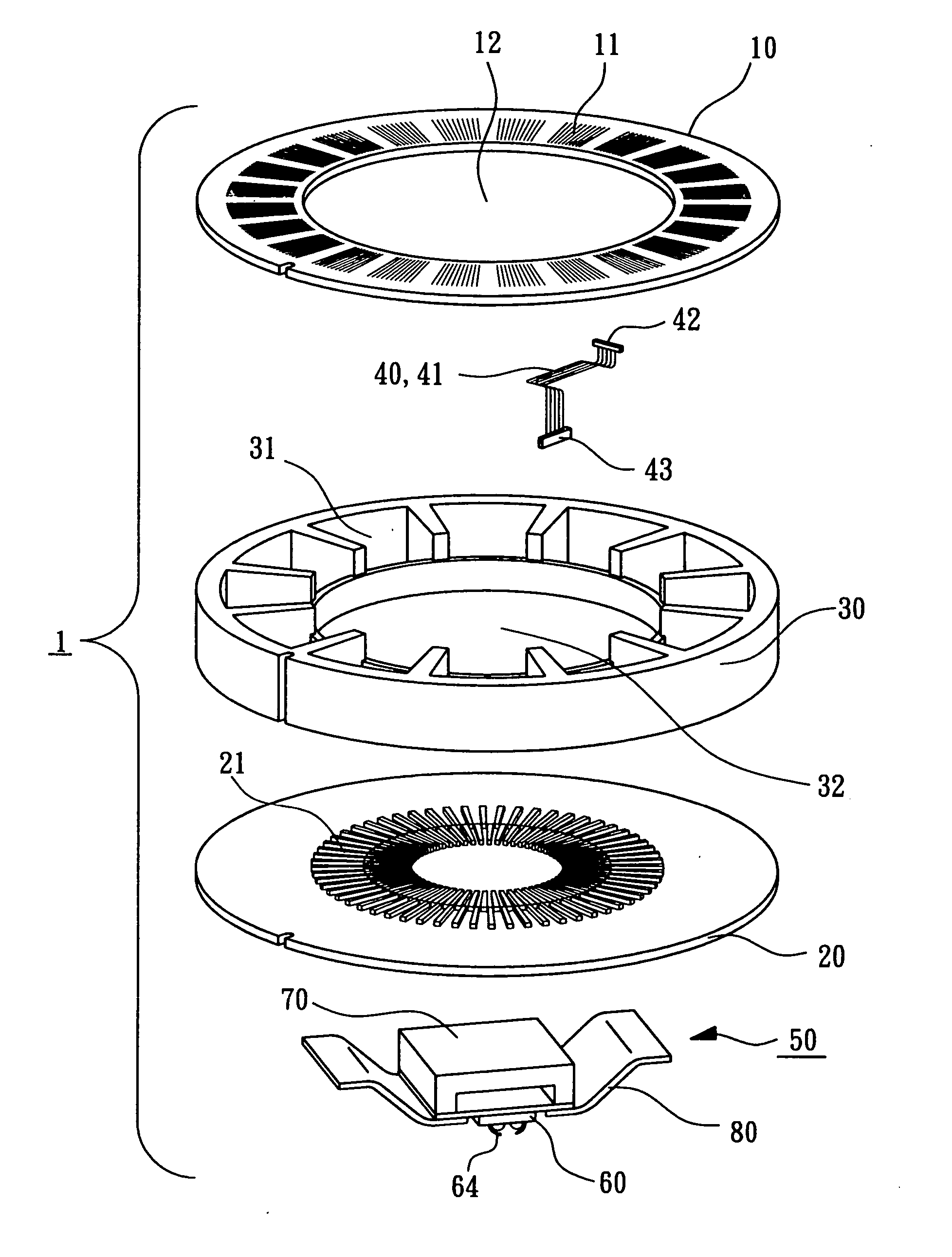

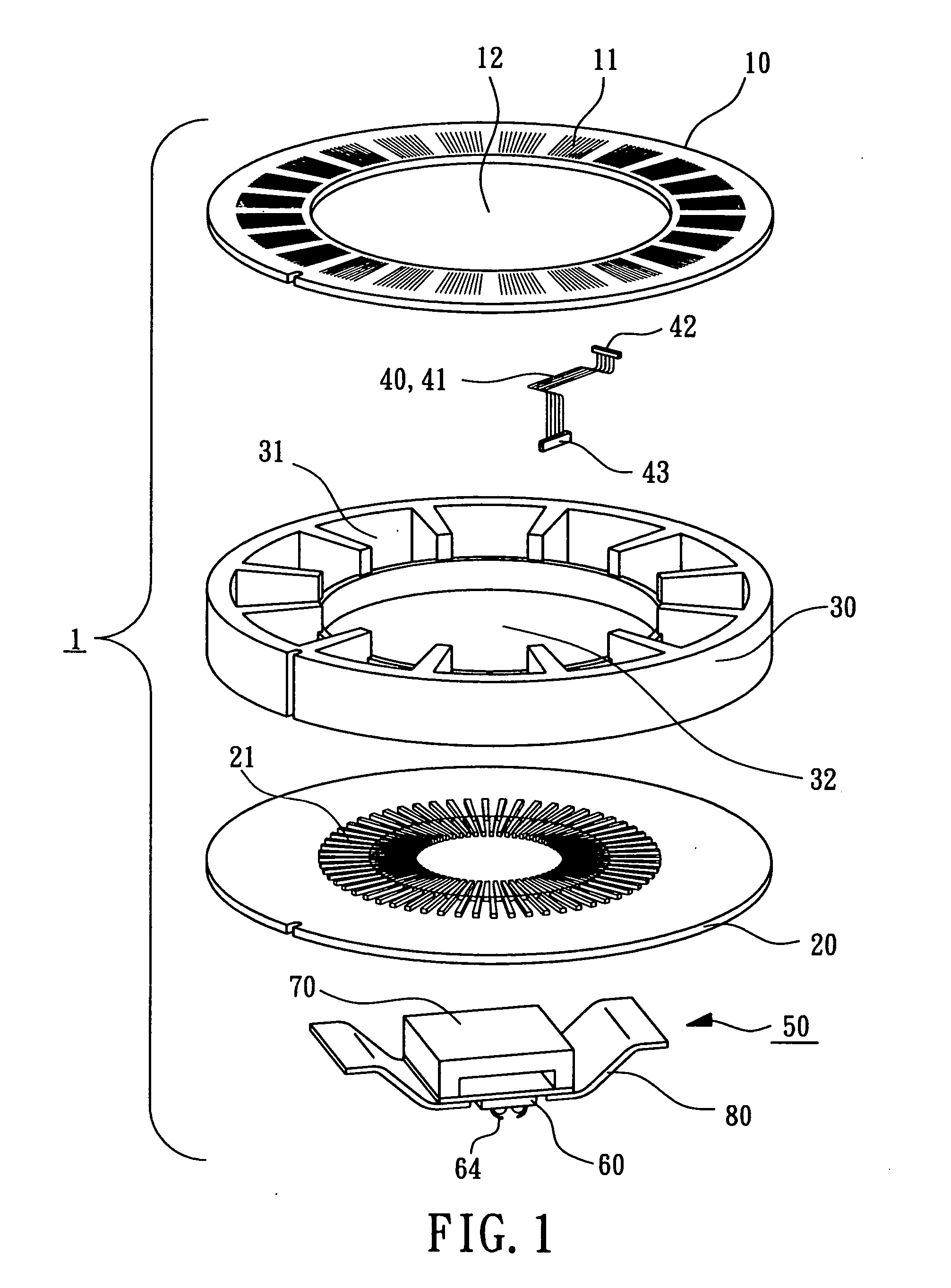

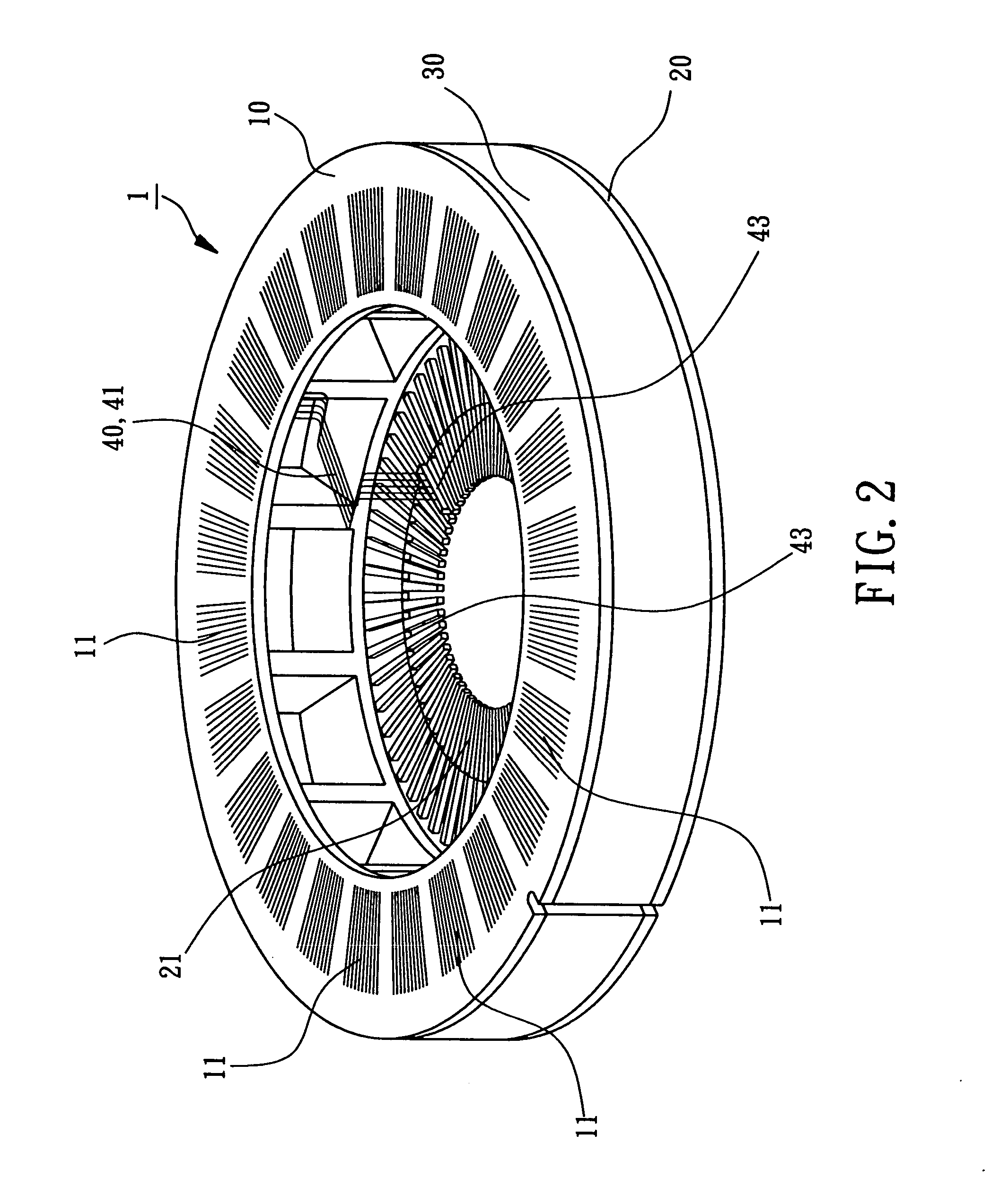

[0014] The first embodiment according to the present invention is shown in FIGS. 1, 2, and 3. A probe card assembly 1 is provided to install on the test head of a tester. The probe card assembly is electrically connected to the tester for electrically contacting with the wafer under test, and allows the tester to perform chip probing or wafer sorting on the wafer. The probe card assembly 1 mainly comprises a stiffener ring 30, an upper printed circuit board 10, a lower printed circuit board 20, a modularized probe head 50, and a plurality of coaxial transmitters 40. Wherein the stiffener ring 30 is functioned as a spacer between the upper and lower printed circuit board 10,20, and to enclose the coaxial transmitters 40. The stiffener ring 30 has an upper opening 31 and a lower opening 32 with different size.

[0015] The upper printed circuit board 10 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com