Voltage increase circuit for elevated voltage charge

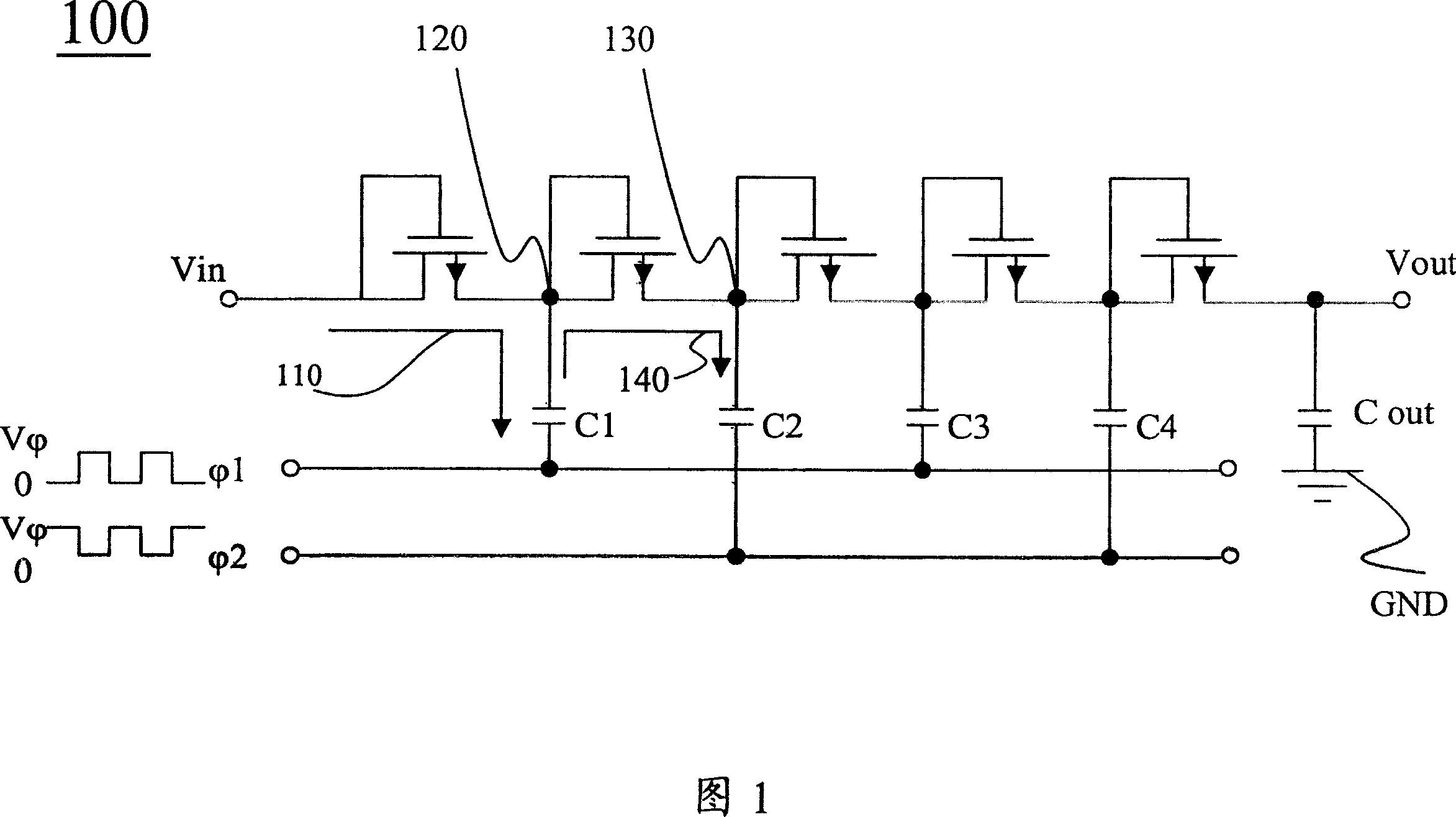

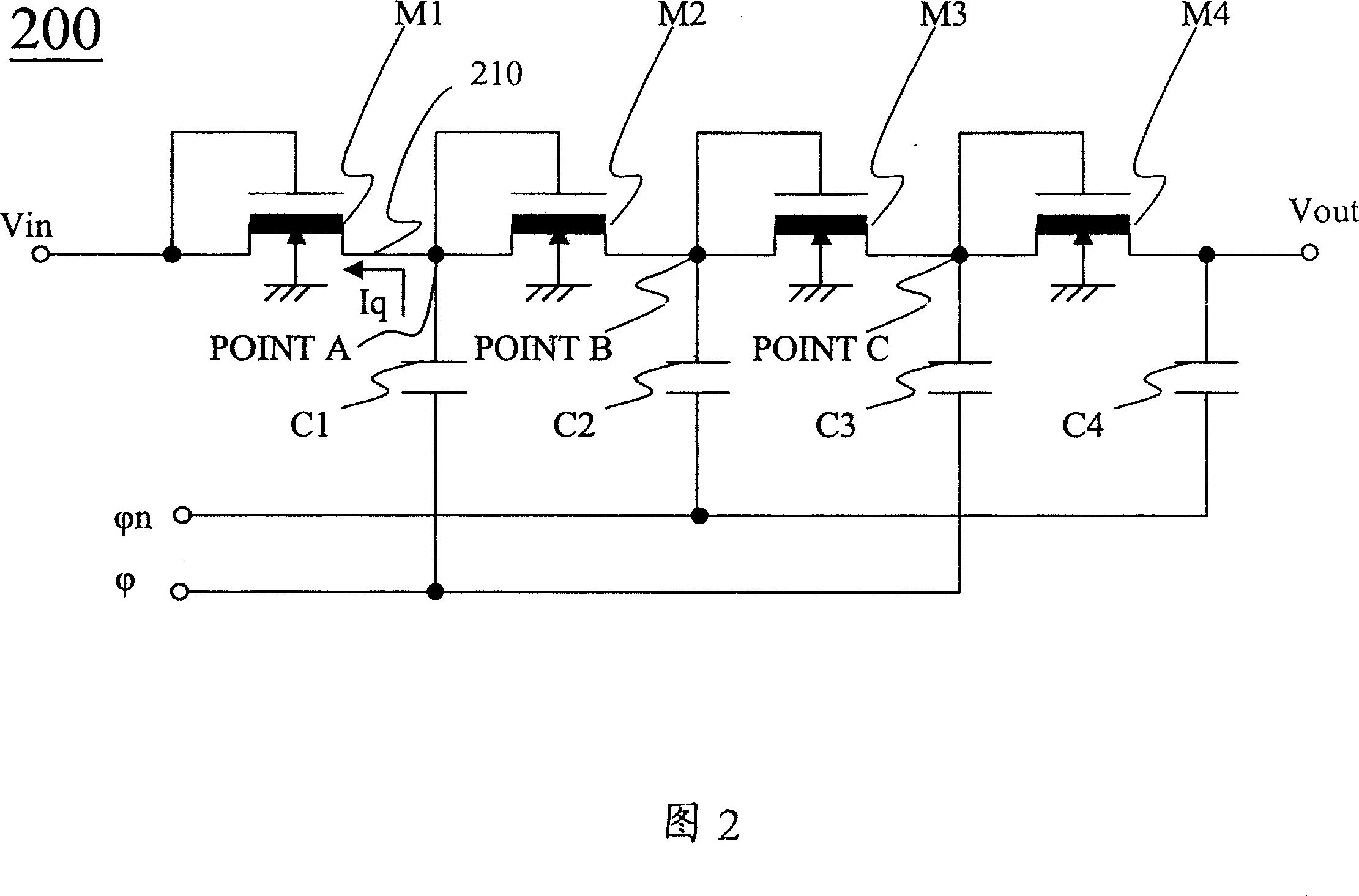

A technology for boosting capacitors and charges, which is applied in the direction of conversion equipment without intermediate conversion to AC, and can solve problems such as system damage, cost rise, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

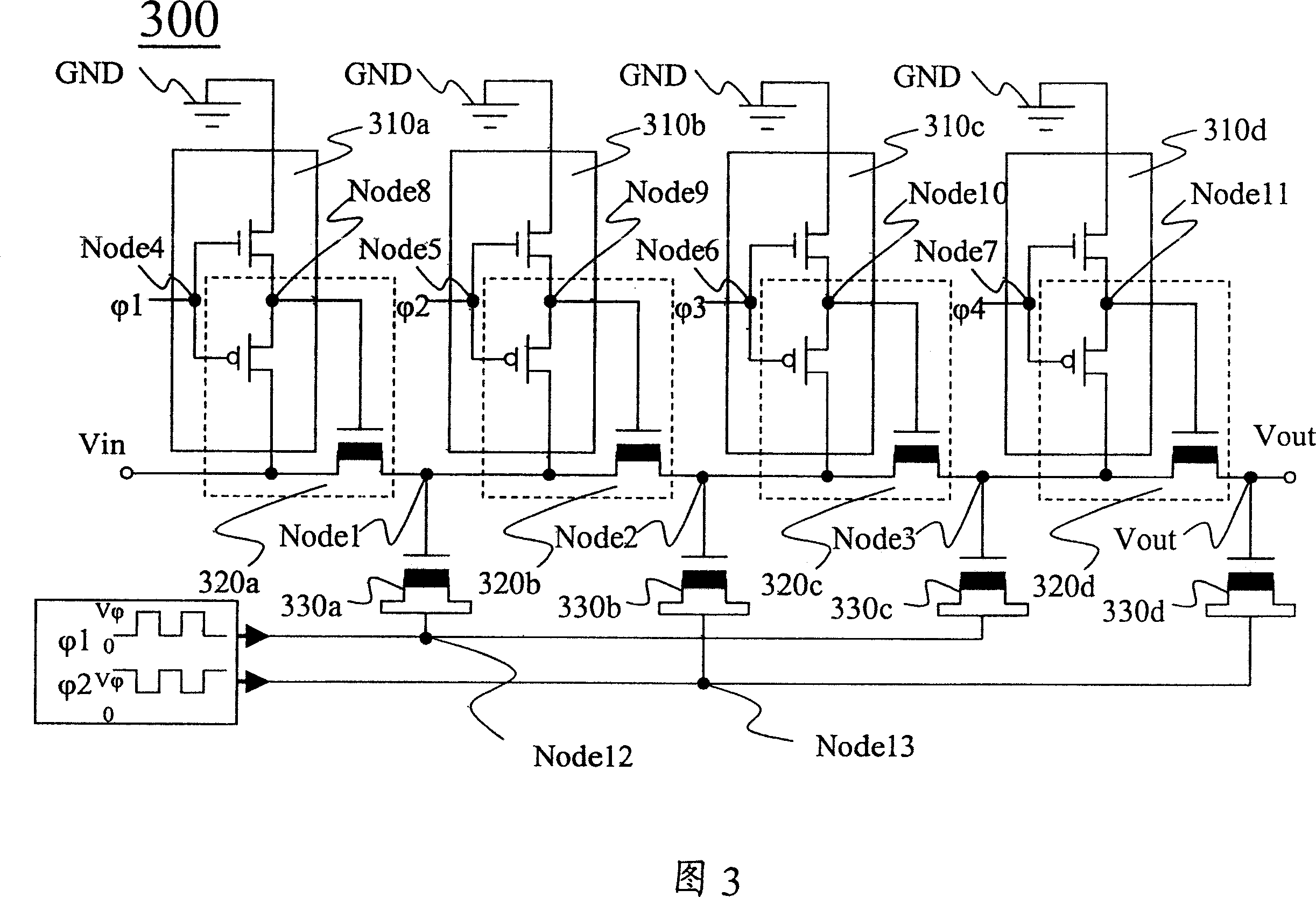

[0039]FIG. 3 is a schematic diagram of a four-order boost charge boosting circuit (4-order Chareg-pump Circuit) 300 disclosed in one of the embodiments of the present invention. The four-order boost charge boost circuit 300 includes a A first reverse current cut-off circuit 310a, a second reverse current cut-off circuit 310b, a third reverse current cut-off circuit 310c, a fourth reverse current cut-off circuit 310d, a first equivalent diode 320a, a second equivalent diode 320b , a third equivalent diode 320c, a fourth equivalent diode 320d, a first boost capacitor 330a, a second boost capacitor 330b, a third boost capacitor 330c and a fourth boost capacitor 330d, wherein Each reverse current cut-off circuit 310 includes a switch pair. In this embodiment, the reverse current cut-off circuit 310 is respectively composed of an enhanced N-channel metal oxide semiconductor transistor (Enhancement-type N-channel Transistor) and an enhanced P channel metal oxide transistor. Semicond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com