Catalysis degreasing type adhesive for powder injection moulding and preparation of material feeding thereof

A technology of powder injection molding and catalytic degreasing, applied in the direction of adhesives, etc., can solve the problems of high production cost, achieve low cost, promote wide application, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A catalytic degreasing binder suitable for 17-4PH stainless steel powder injection molding, which consists of the following components (volume percentage ratio): 89% polyoxymethylene 100P, 5% high-density polyethylene, 3% paraffin, 1% ethylene-vinyl acetate copolymer (EVA) with a vinyl acetate (VA) content of 26, 1% dibutyl phthalate, 1% zinc stearate.

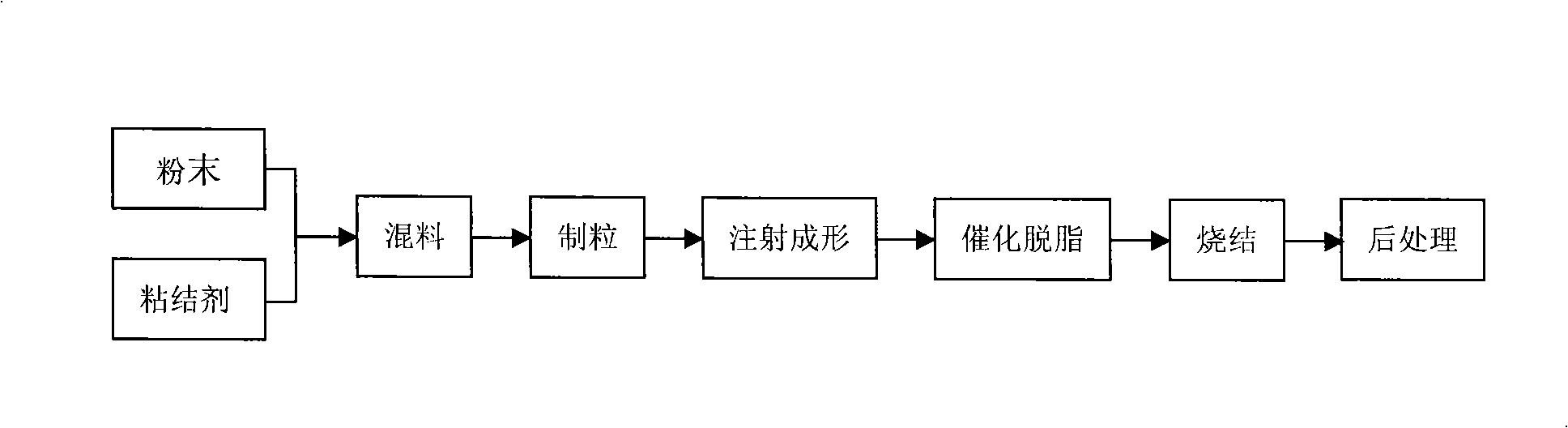

[0040] Such as figure 1 Shown, the preparation method of the present embodiment comprises the following steps:

[0041] (1) 89% polyoxymethylene 100P, 5% high-density polyethylene, 1% ethylene-vinyl acetate copolymer (EVA) with a vinyl acetate (VA) content of 26, and 17-4PH with a powder loading of 62% The stainless steel powder was added into a three-dimensional rotator and dry mixed for 1 hour to obtain a uniform mixture of powder and binder.

[0042] (2) Put the above homogeneous mixture into the internal mixer, raise the temperature to 185°C, and knead for 30 minutes.

[0043] (3) Reduce the mixing temperature to...

Embodiment 2

[0046] A catalytic degreasing binder suitable for zirconia ceramic powder injection molding, which consists of the following components (volume percentage ratio): 90% polyoxymethylene 500P, 4% high-density polyethylene, 3% paraffin, 1 Ethylene-vinyl acetate copolymer (EVA) with a % vinyl acetate (VA) content of 24, 1.5% dibutyl phthalate, 0.5% zinc stearate.

[0047] The preparation method of this embodiment:

[0048] (1) 90% polyoxymethylene 500P, 4% high-density polyethylene, 1% ethylene-vinyl acetate copolymer (EVA) with a vinyl acetate (VA) content of 24, and zirconia ceramics with a powder loading of 53% The powder was added to a three-dimensional rotator and dry mixed for 1 hour to obtain a uniform mixture of powder and binder.

[0049] (2) Put the above homogeneous mixture into the internal mixer, raise the temperature to 190°C, and knead for 25 minutes.

[0050] (3) Reduce the mixing temperature to 165°C, then add 3% paraffin, 1.5% dibutyl phthalate and 0.5% stearic ac...

Embodiment 3

[0053] A catalytic degreasing binder suitable for YG12 hard powder injection molding, which consists of the following components (volume percentage ratio): 89% polyoxymethylene 100P, 5% high-density polyethylene, 3% paraffin, 1 Ethylene-vinyl acetate copolymer (EVA) with a vinyl acetate (VA) content of 26%, 1% dibutyl phthalate, 1% zinc stearate.

[0054] The preparation method of this embodiment:

[0055] (1) 89% homopolyoxymethylene 100P, 5% high-density polyethylene, 1% ethylene-vinyl acetate copolymer (EVA) with a vinyl acetate (VA) content of 26, and YG12 rigid with a powder loading of 56% The powder was added to a three-dimensional rotator and dry mixed for 1 hour to obtain a uniform mixture of powder and binder.

[0056] (2) Put the above homogeneous mixture into the internal mixer, raise the temperature to 185°C, and knead for 30 minutes.

[0057] (3) Reduce the mixing temperature to 170°C, then add 3% paraffin wax, 1% dibutyl phthalate and 1% stearic acid into the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com