A kind of uv debonding adhesive, its preparation method and uv debonding film

An adhesive and debonding technology, which is applied in the field of UV debonding adhesives and UV debonding films, can solve the problems of inconvenient peeling of wafer slices, high peeling force, and limited performance, and achieve good adhesion and peeling force. High, fast debonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

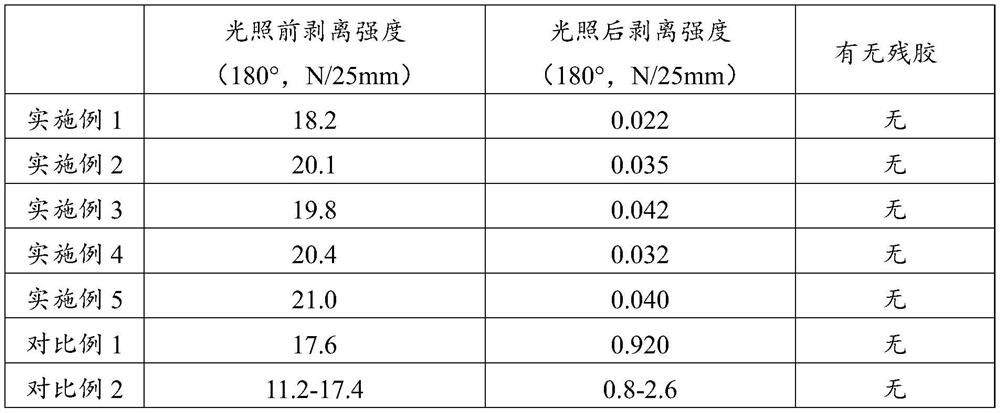

Examples

Embodiment 1

[0025] 1. Preparation of Raw Gum

[0026] Weigh 40 parts of isooctyl acrylate, 48 parts of methyl acrylate, 2 parts of acrylic acid, 2 parts of methyl methacrylate, 3 parts of carboxyethyl acrylate, 5 parts of vinyl acetate, 0.1 part of azobisisobutyronitrile, 0.15 parts of amyl peroxypivalate, 150 parts of ethyl acetate, and 65 parts of toluene. Stir each component evenly at room temperature in the reactor, and the temperature of the reactor is raised to 65-80°C to carry out the polymerization reaction. The reaction time is 8-80°C. 10h, the original gum was obtained.

[0027] 2. Preparation of Adhesive

[0028] Weigh 100 parts of the above raw rubber, 5 parts of terpene phenolic resin (softening point 120°C), 5 parts of rosin modified phenolic resin (softening point of 120°C), 4 parts of trifunctional aliphatic urethane acrylate oligomer, six-functional 12 parts of aliphatic urethane acrylate oligomer, 0.1 part of epoxy resin curing agent, 2 parts of 1-hydroxycyclohexyl phe...

Embodiment 2

[0032] 1. Preparation of Raw Gum

[0033] Weigh 40 parts of isooctyl acrylate, 48 parts of methyl acrylate, 2 parts of acrylic acid, 2 parts of methyl methacrylate, 3 parts of carboxyethyl acrylate, 5 parts of vinyl acetate, 0.1 part of azobisisobutyronitrile, 0.15 parts of amyl peroxypivalate, 150 parts of ethyl acetate, and 65 parts of toluene. Stir each component evenly at room temperature in the reactor, and the temperature of the reactor is raised to 65-80°C to carry out the polymerization reaction. The reaction time is 8-80°C. 10h, the original gum was obtained.

[0034] 2. Preparation of Adhesive

[0035] Weigh 100 parts of the above raw rubber, 2 parts of terpene phenol resin (softening point 125°C), 4 parts of three-official aliphatic urethane acrylate oligomer, 20 parts of nine-official aliphatic urethane acrylate oligomer, epoxy 0.2 parts of resin curing agent, 2 parts of 1-hydroxycyclohexyl phenyl ketone, 2 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide,...

Embodiment 3

[0039] 1. Preparation of raw gum:

[0040] Weigh 40 parts of isooctyl acrylate, 48 parts of methyl acrylate, 2 parts of acrylic acid, 2 parts of methyl methacrylate, 3 parts of carboxyethyl acrylate, 5 parts of vinyl acetate, 0.1 part of azobisisobutyronitrile, 0.15 parts of amyl peroxypivalate, 150 parts of ethyl acetate, and 65 parts of toluene. Stir each component evenly at room temperature in the reactor, and the temperature of the reactor is raised to 65-80°C to carry out the polymerization reaction. The reaction time is 8-80°C. 10h, the original gum was obtained.

[0041] 2. Preparation of Adhesive

[0042] Weigh 100 parts of the above raw rubber, 4 parts of terpene phenol resin (softening point 140°C), 4 parts of three-official aliphatic urethane acrylate oligomer, 24 parts of nine-official aliphatic urethane acrylate oligomer, epoxy 0.2 parts of resin curing agent, 2 parts of 1-hydroxycyclohexyl phenyl ketone, 2 parts of 2,4,6-trimethylbenzoyl-diphenylphosphine oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com