Machining device and machining method for enhancing sapphire laser back wet etching rate

A wet etching and processing device technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of liquid can not overflow in time, difficult to process, reduce processing efficiency, etc., to enhance the laser etching rate, Reduced pressure difference and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

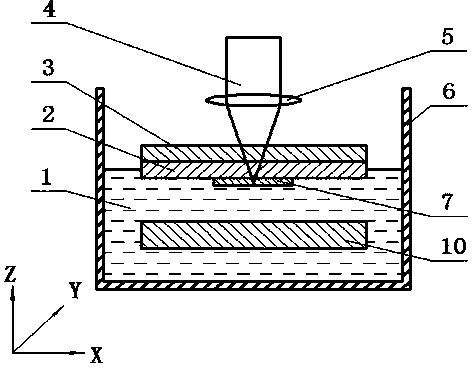

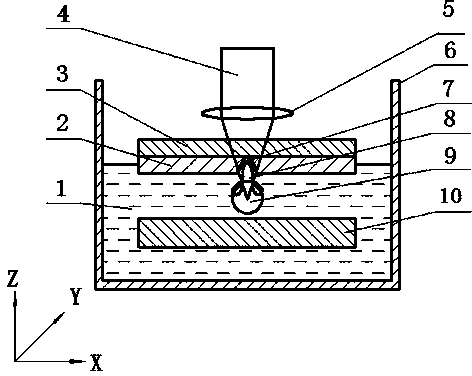

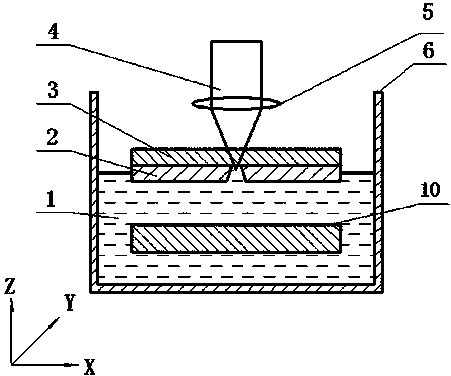

[0024] The structure diagram of the present invention is as figure 1 , 2 , 3, the processing device of the strong sapphire laser facing away from the wet etching rate of the present invention includes a protection device 3, a laser beam 4, a lens group 5, a container 6, and a confinement layer 10, wherein the container 6 is set in a hollow cavity A working fluid 1 is installed, the workpiece 2 is placed on the surface of the working fluid 1 and is in contact with the working fluid 1, the protection device 3 is installed on the top surface of the workpiece 2, the limiting layer 10 is installed under the workpiece 2, and the laser beam 4 passes through The lens group 5 illuminates the back side of the workpiece 2 .

[0025] The above-mentioned working liquid 1 is CuSO with a mass concentration that can be adjusted within the range of 1 to 25% for laser-induced photochemical deposition. 4 solution or CuSO 4 mixture. In the present embodiment, the above-mentioned working liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com